Table of Contents

In This article we will discuss various type of load cell which are being defined by the manufacturers. Also we will know “Load cell manufacturers in India”.

Load cell manufacturers in India

There are many Load cell brands, manufactures and suppliers available. Here some of Load cell manufacturers in India are mentioned below. Follow the link to read more about them.

- Zemic Load cell

- Load cell arduino

- Adi load cell

- Aditech load cell

- Rudrra load cell

- flintec load cell

- hbm load cell

- Sensomatic load cell

- Sensotec load cell

- Keli load cell

- Digikey load cell

- Mettler toledo load cell

- Syscon load cell

- Scaime load cell

- Gefran load cell

- Nmb load cell

- Wika load cells

- Tecsis load cell

- Ipa load cell

- Burster load cell

- Sushma load cell

- Jisl load cell

- Scaime load cell

- Honeywell load cell

- Laumas load cell

- Epoch load cell

- Omega load cell

- Kistler load cell

- Thames load cell

- Rice lake load cells

- Vishay load cell

- Siemens load cell

- Unipulse load cell

Various Types of load cell-

Based on different characteristics like size, shape, capacity and applications accordingly, several other load cell types are as mentioned below-

Single Point load cells-

Single point load cells are a type of load cell, they are a very popular choice and account for the largest percentage of load cells worldwide. Single point load cells provide high accuracy and high reliability, they are also known as “platform load cells” because this is their most common application. They are typically used in compact weighing systems with low capacity. Single point load cells are unique in that they can accept an off-center load, which means they will measure weight accurately if it is placed anywhere on the scale, therefore, they are highly accurate in industrial applications. is allowed to happen.

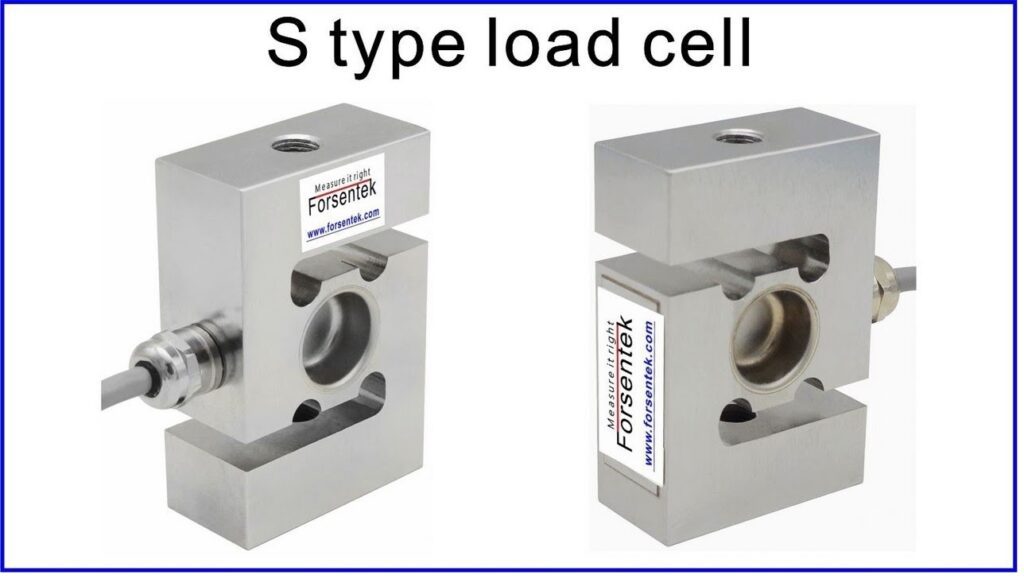

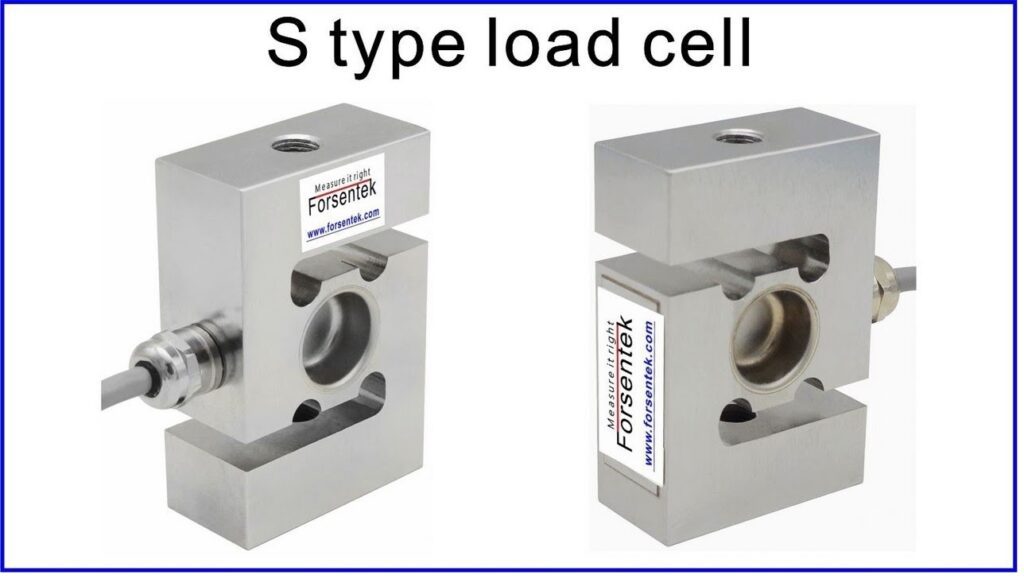

S-type load cell

Unlike other typical load cells, they are known by their shape like “S type” as shown in figure. sometimes it is referred as term “Z type”. S type load cells are primarily used for mechanical-to-electronic scale conversions, but are also used for many other different applications such as hanging scales, hopper scale, crane scaling, tank weighing etc. The capacity of S type load cells we can supply ranges from 25kg to about 30tons mainly using metal foil strain gauge technology. These s type cells are a successful choice for applications as they provide accuracy and have compact design features. Installation using a rod end or load button means that S Type load cells deliver excellent performance in both tension and compression applications.

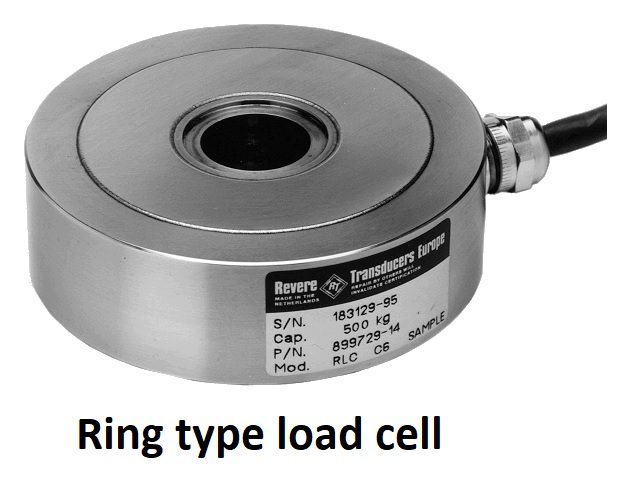

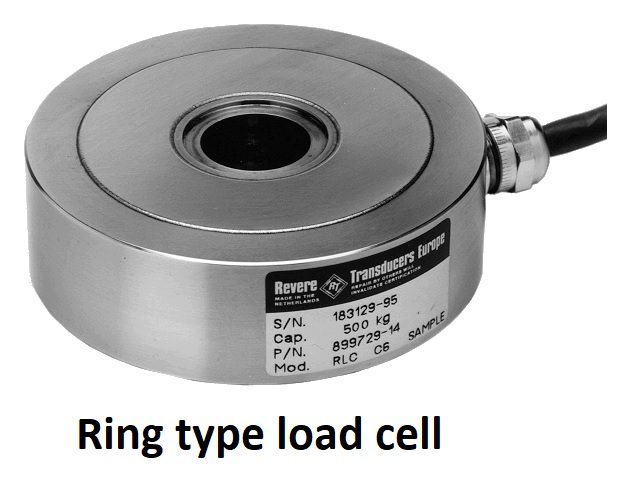

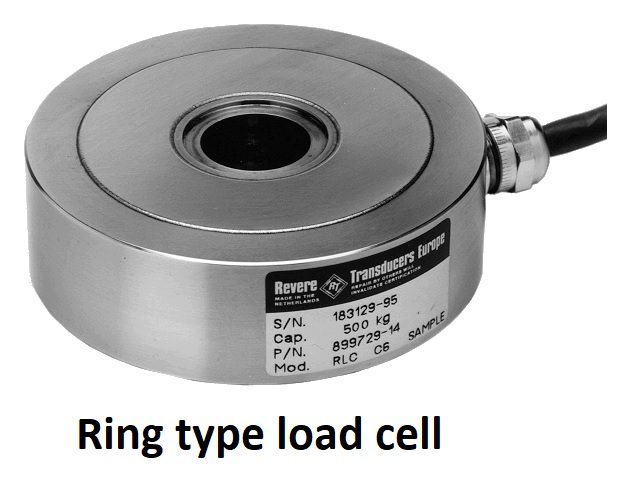

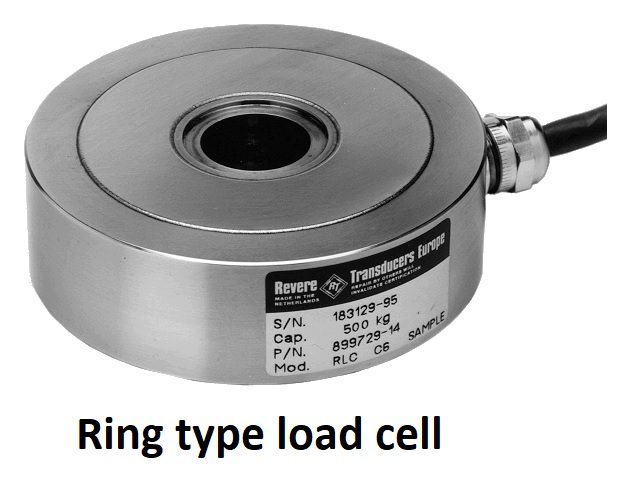

Ring type load cell

As like S type load cell, Ring load cell also known by their shape like a “ring”. They are also called as Ring Torsion load cells. Ring-torsion load cell strain gauges are based on the basic principle of load cells. Ring-torsion measurement theory offers a wide range of applications. For example, it is suitable for load levels for which previously only shear and load beams could be used. From a design perspective, this specification covers a predominantly flat ring load cell of stainless steel with multiple circular DMS load cells arranged in a full-bridge circuit. They offer excellent versatility and is now available for platform scales as well as for weighing applications like hoppers, silo’s, platforms and pallet scales etc. a diagram of ring type load cell is given below-

Canister load cell-

Canister load cells are cylindrical shaped cells and ideal for high accuracy applications. They are used in applications such as weighing, quality control, tactile forces, and static material test machines, Canister style load cells also include a built-in mounting base for a simplified installation in both tension and compression applications. these load cells are often used in truck scales, vessel weighing, and press applications. Canister load cells are desirable when medium to high capacities and high accuracy are required. Standard capacities are available from as low as 25,0 lbs to capacities as high as 200,000 lbs.

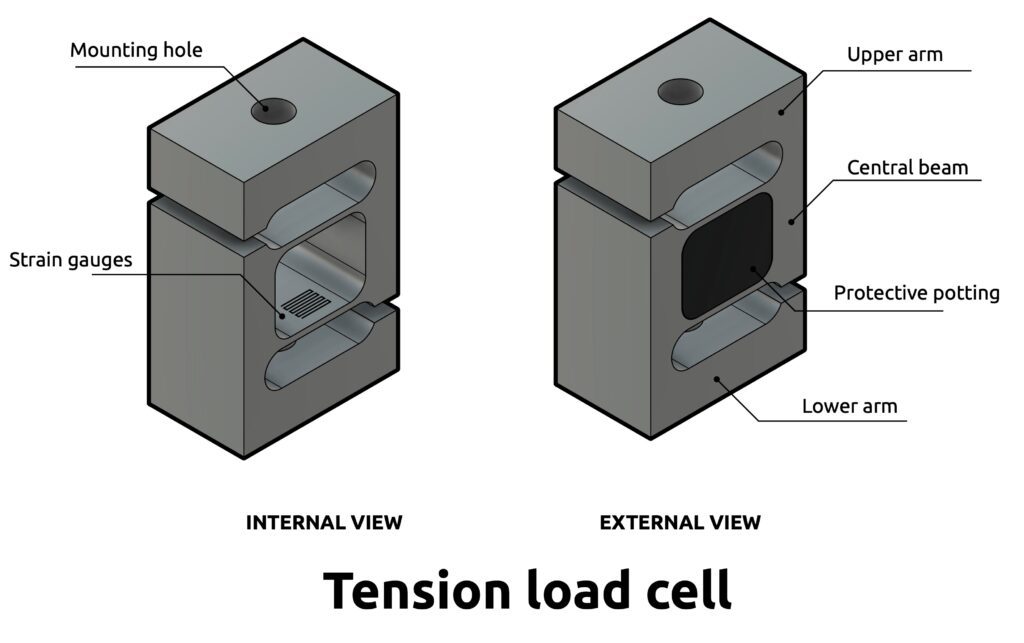

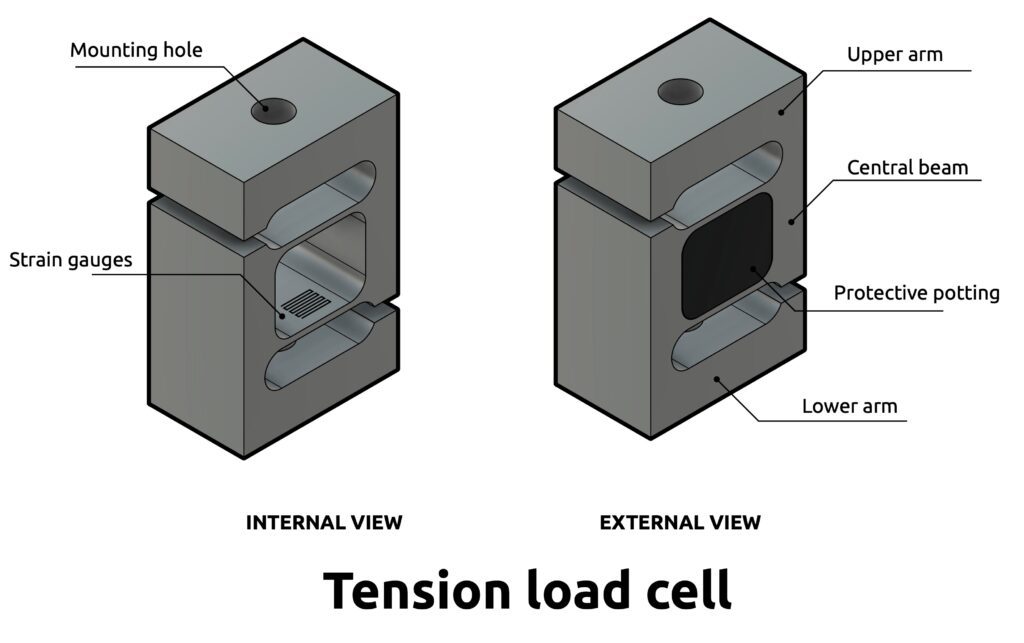

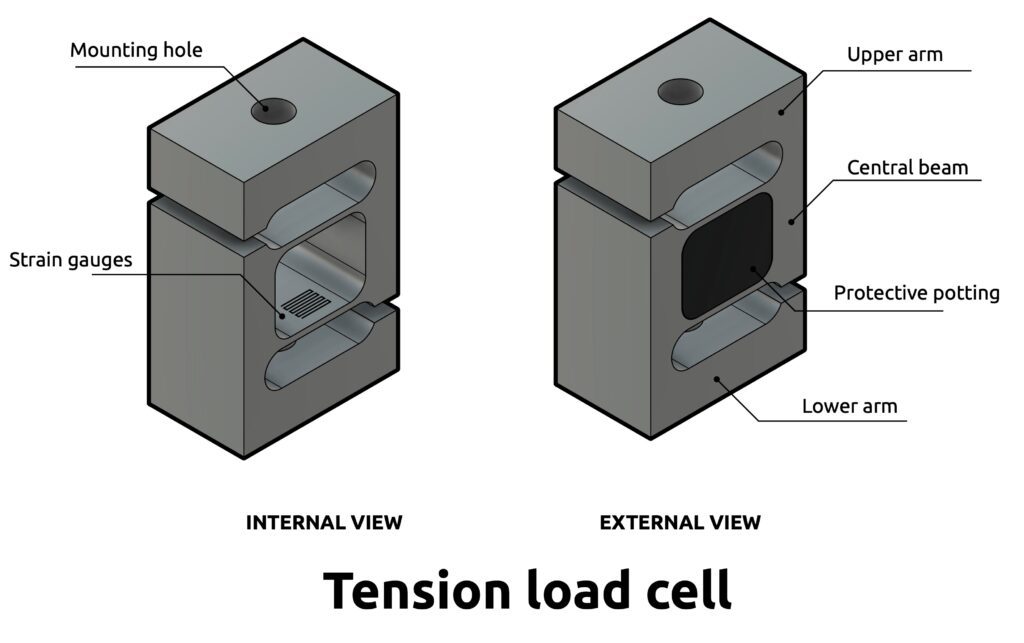

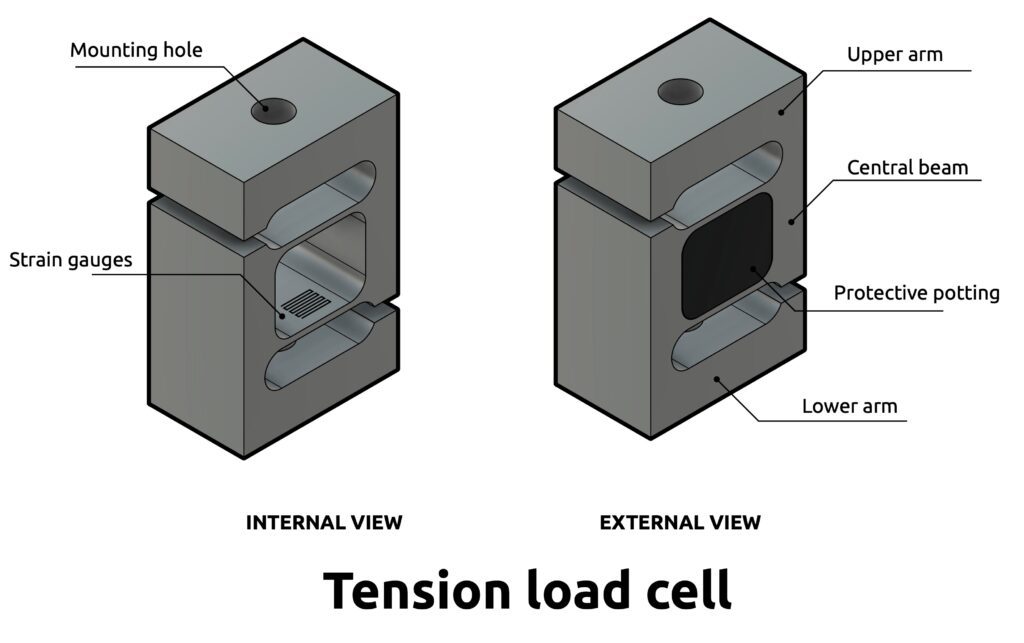

Tension load cell

Tension load cells are one of the major categories commonly found within the weighing industries. Tension load cells are primarily used to sense tensile force, load, stress, and convert to electrical form. A tensile load cell is pulled apart rather than bent or compressed. Many tensile load cells have bi-directional sensitivity, so they can also measure compression. Tension load cells are designed to be adapted to applications that involve suspended loads. As such, they are often required to sit in line with the dependent object, which is usually integrated into the accessories. Tension links, S-type load cells, crane scales, canisters and pancakes are examples of tension load cells. A diagram for tension load cell is shown below-

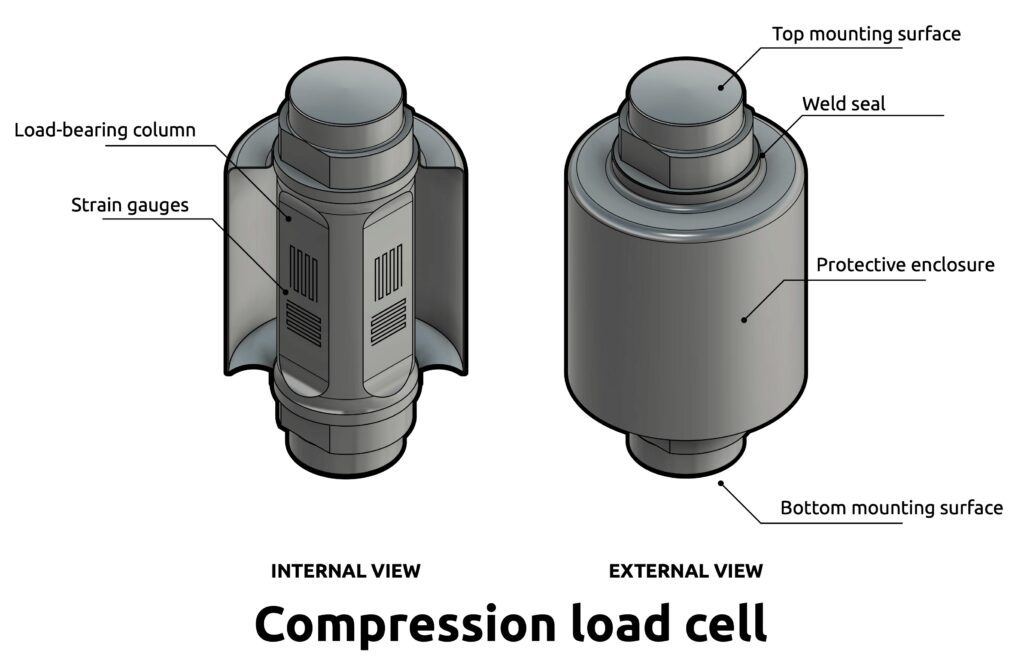

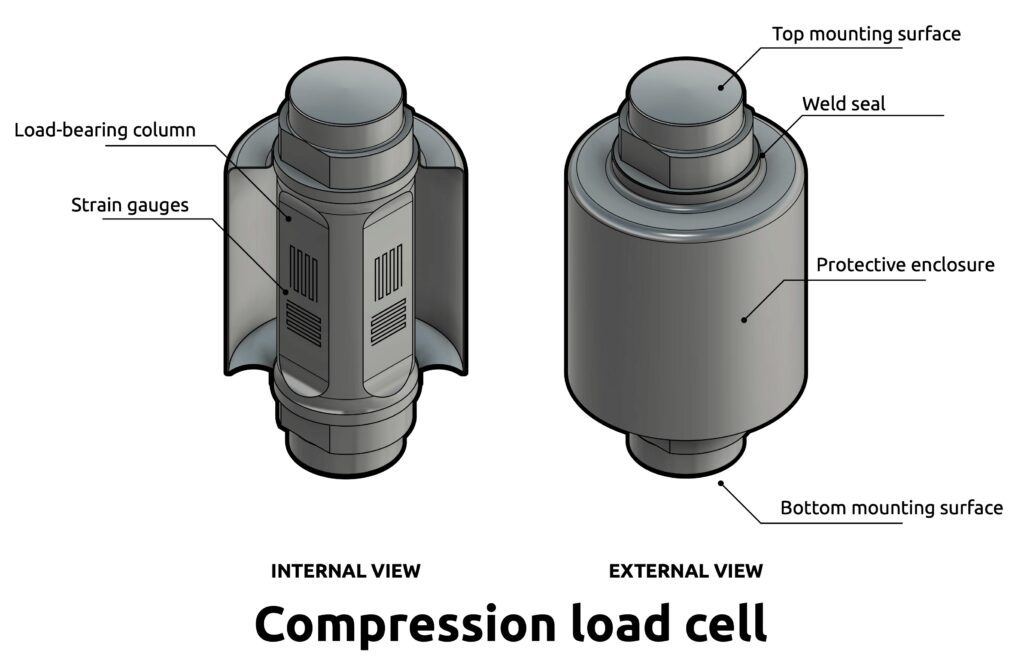

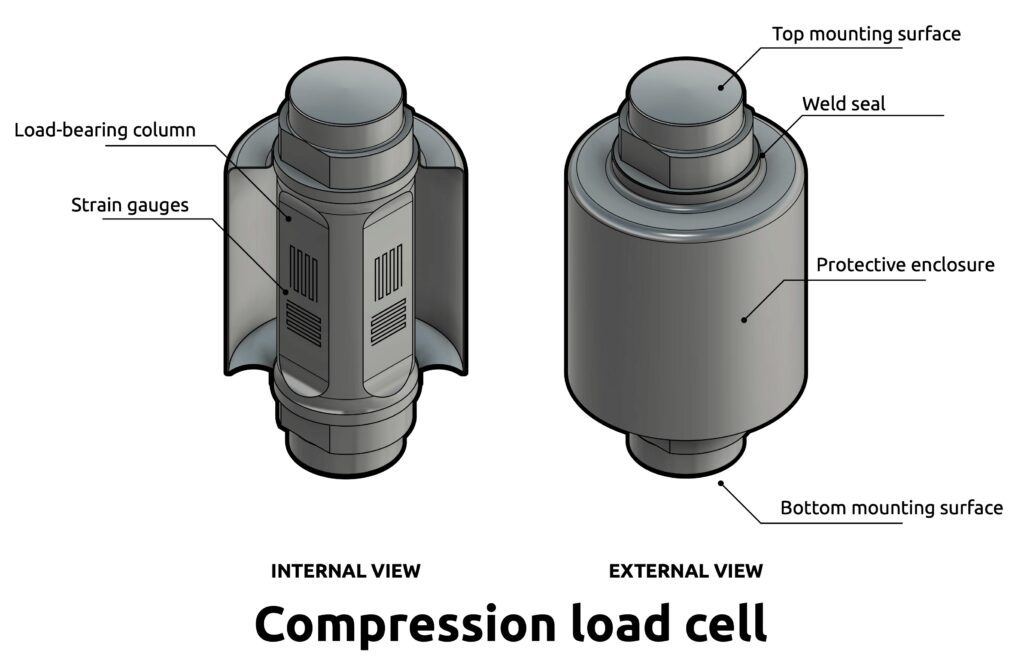

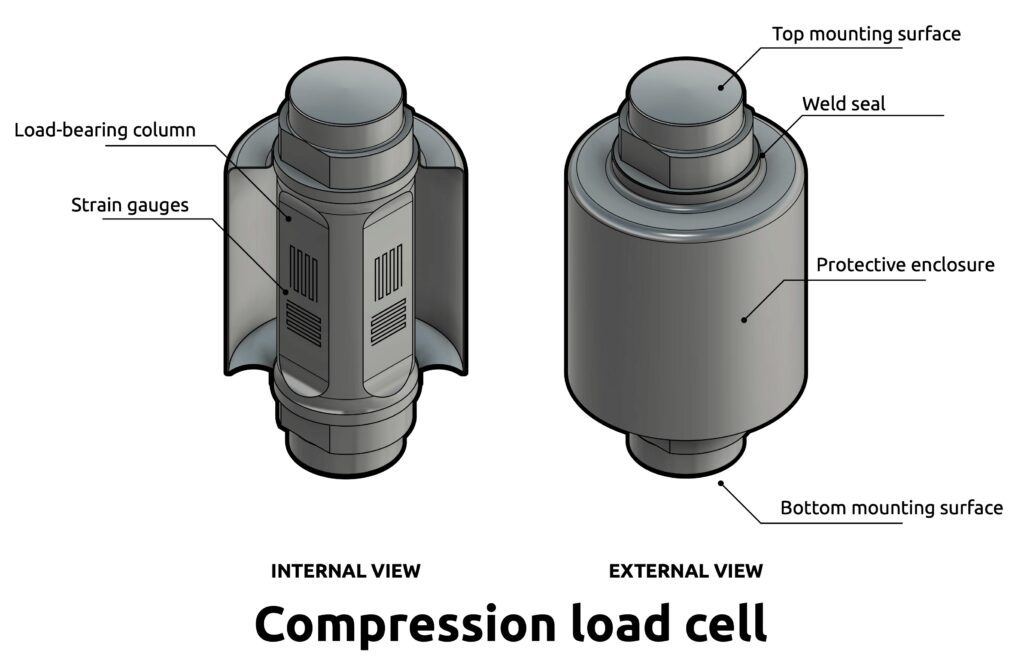

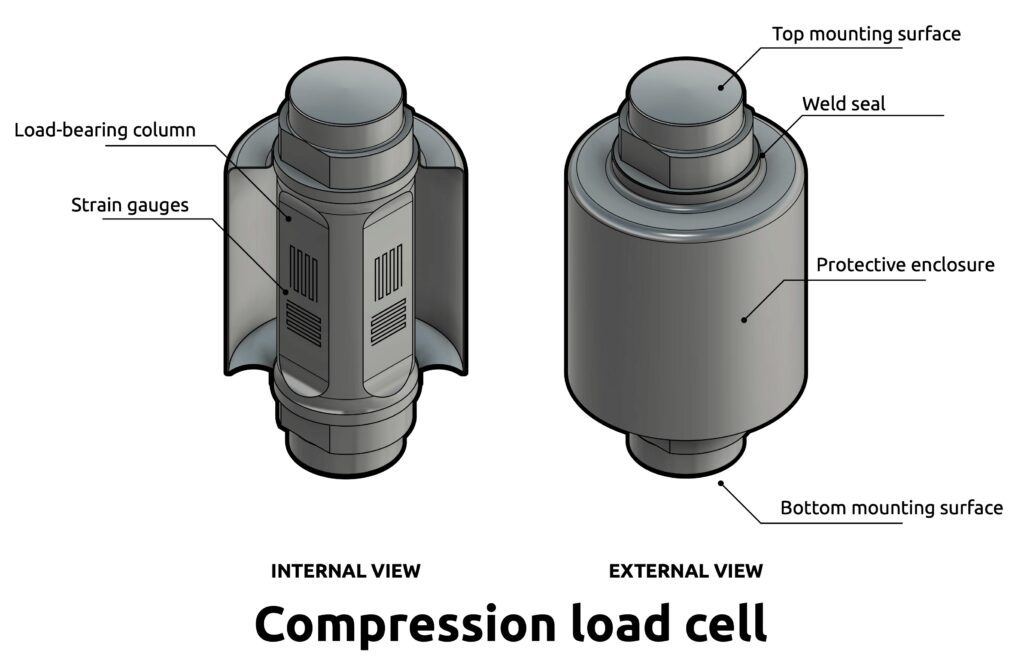

Compression load cell

Compression load cell is another major category commonly found within the weighing industries. Compression load cells are mostly column shaped force sensors or canister style load cell. These load cells are primarily used for deflection of compression or compressive load strain as name suggest. , compression load cell measures a pushing force along a single axis. Generally, a compression load cell is placed beneath the object that’s weight, or compressive load to be measured. The strain gauge gets deformed on applying compression load, and this deformation is used to produce the measurement. These load cells are highly accurate and specifically designed for application where space is limited, as they can be built to be extremely compact. They are ideal for use for extremely high capacity loads. A diagram for compression load cell is shown below-

Beam load cell

A beam load cell is based on a simple cantilever beam that is flexible to either bend when subjected to a weight/ load or shear when applying a shearing force. Typically bending beam load cell are used to measure longitudinal force or load. Bending beam cell application includes filling machinery, industrial floor scales, tank and silo weighing, on-board vehicle weighing etc. while shear beam cell offers excellent stability in the case of lateral forces. Shear strains do not vary when the load application point moves within a certain range. Shear beam load cells are installed in industries where goods are produced or transformed. Shear beam load cell are having a wide range of applications such as platform scales or fixed suspended weigh systems, medical equipment and process control or process weighing and low profile installations. Both the types of beam load cells diagram is mentioned below-

There are several categories to define beam load cell as mentioned below-

- S beam load cell

- Bending Beam load cell

- Shear beam load cell

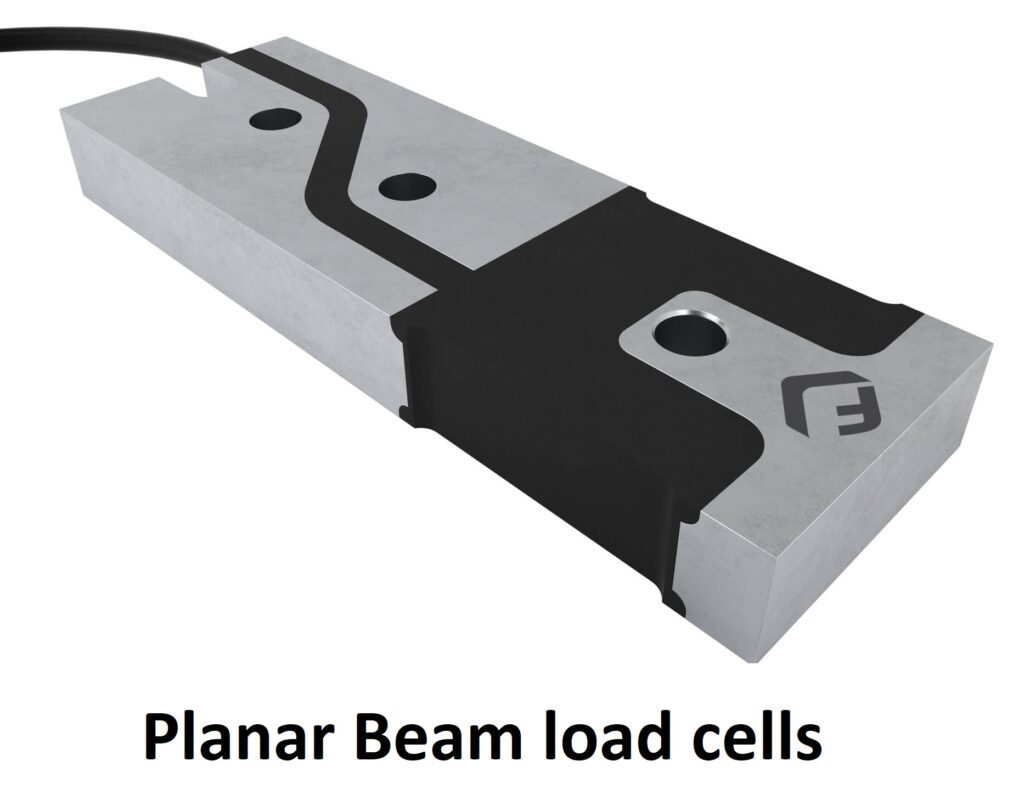

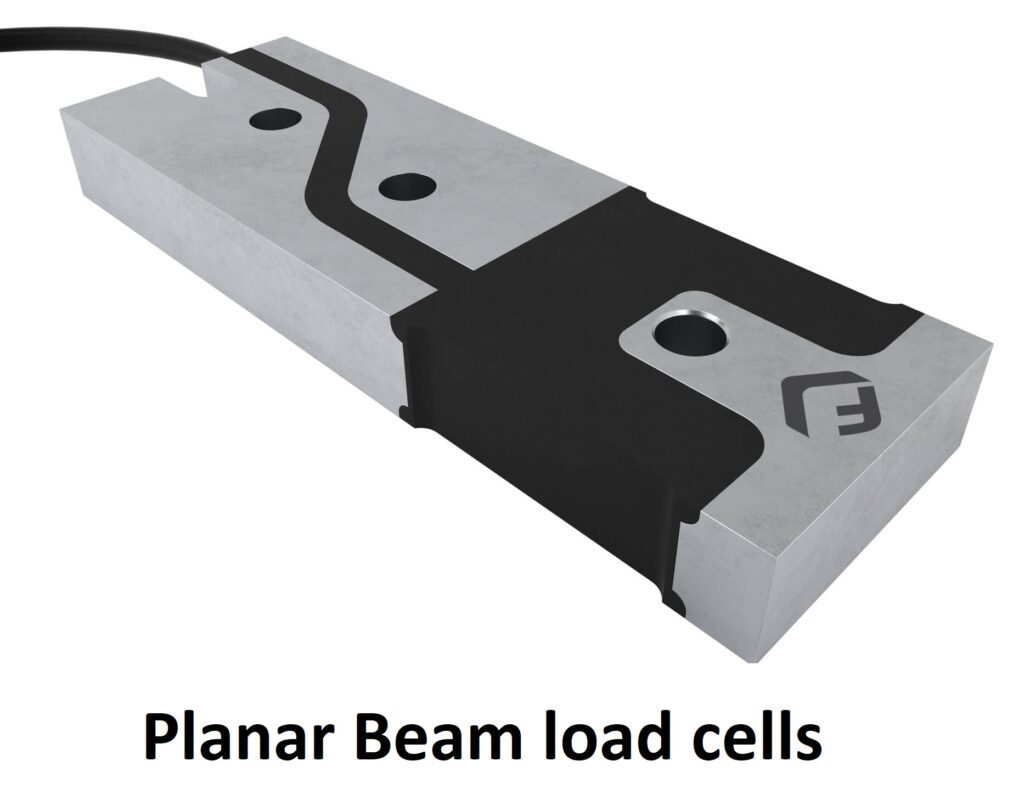

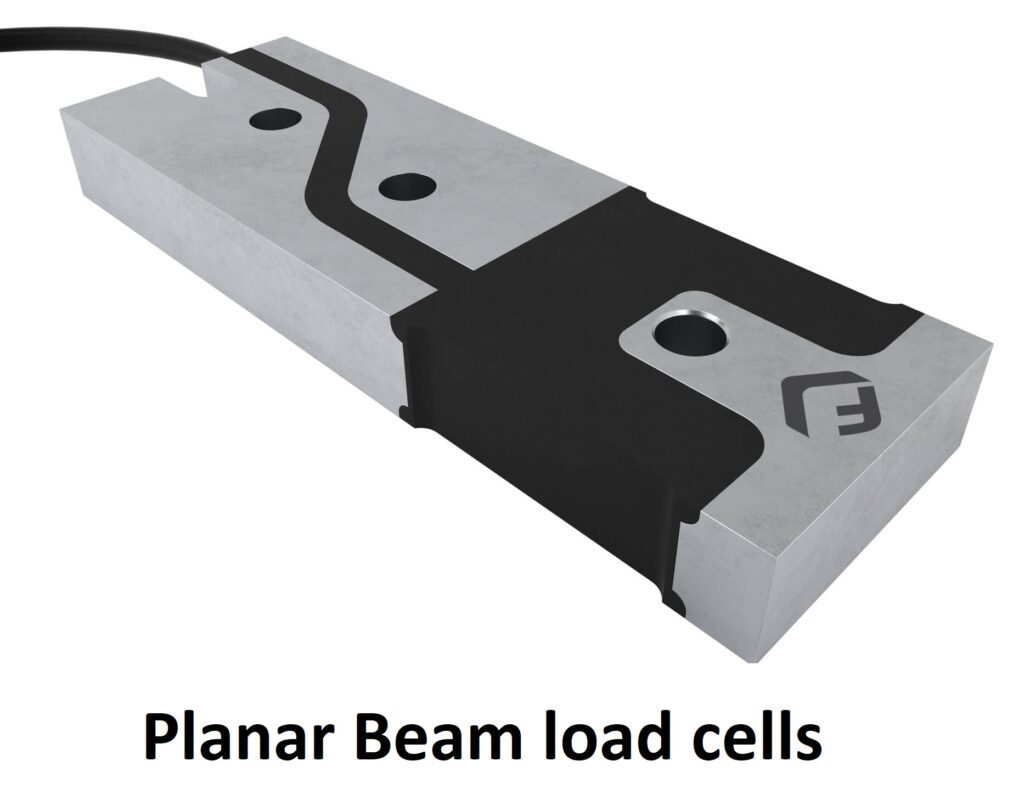

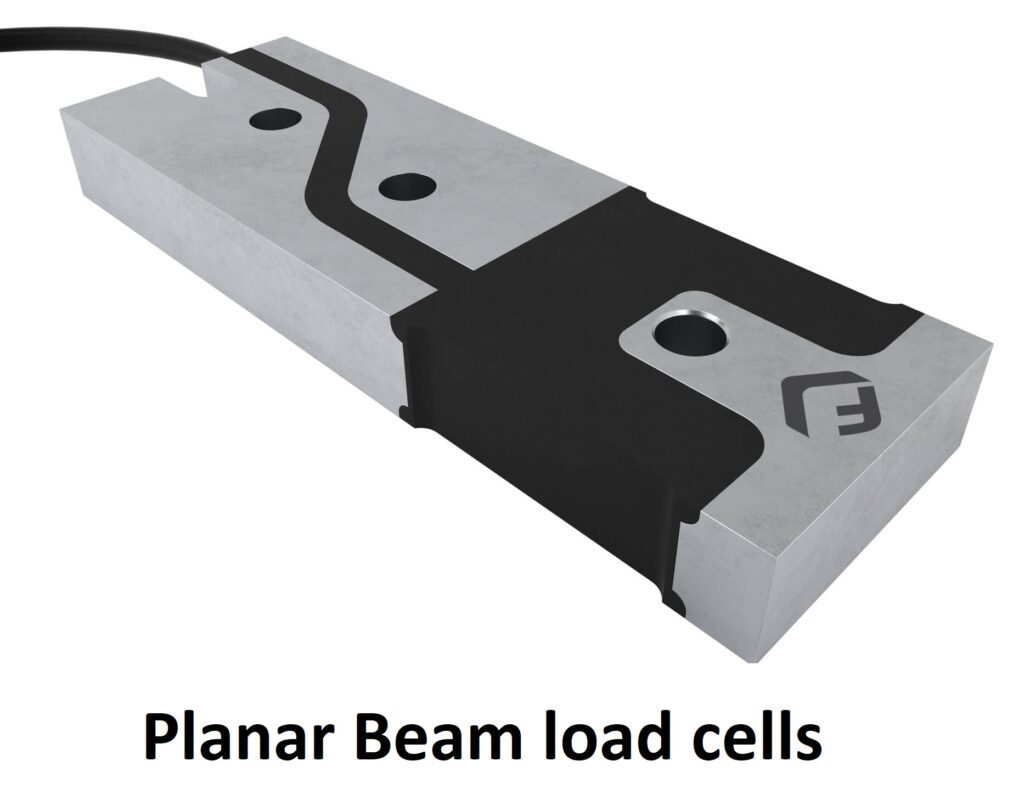

- Planar Beam load cells

- Dual Shear Beam load cells

- Double ended beam load cell

- Single ended shear beam load cell, etc.

To read more about other related topics click on individual links here-

- What is a Load cell?

- Load Cell Types based on working principle

- Digital Load cell

- Load cell wiring and calibration

- What is strain gauge?

- Types of strain gauges

- What is Gauge Factor?