Table of Contents

Pressure transmitter is an instrument that is designed for pressure measurement in gases, liquids, air or oil. Pressure transmitters are widely used in various industrial processes, such as filtration plants, chemical feed, wastewater industries, food industries, pumping stations, and more. Due to their general demand, pressure transmitters are highly customizable by variables such as pressure range, accuracy, connection type, output, IP class and even more.

With so many applications, in order to choose the right pressure transmitter, we need to look at what types of pressure transmitters are there, what do pressure transmitters do and how do pressure transmitters work?

Pressure Transmitter Function

Pressure transmitters measure pressure in various mediums (liquids, liquids, gases) and alert their users when there is a wide difference in range. Thus pressure transmitters help prevent accidents in industrial processes. Although all pressure transmitters have the same pressure measurement function, the applications may vary slightly depending on the different types of pressure transmitters.

Types of pressure transmitters

Pressure transmitters are of different types according to the requirement such as – liquid, gas. There are also different methods according to the condition such as – high temperature, very working temperature, high pressure.

1. Standard Pressure Transmitters

They are compact, universal devices designed for almost all industrial applications and have a main purpose of measuring the pressure range.

2. Hydrostatic Pressure Transmitters

Often called level transmitters because of their working principle and ability to measure levels. Hydrostatic pressure transmitters work on the premise that the amount of pressure increases with depth.

3. Absolute pressure transmitter–

Used in cases when the pressure of gases or liquids is different from changes in atmospheric pressure. These pressure transmitters will be used when the pressure being measured is not affected by any change (such as temperature).

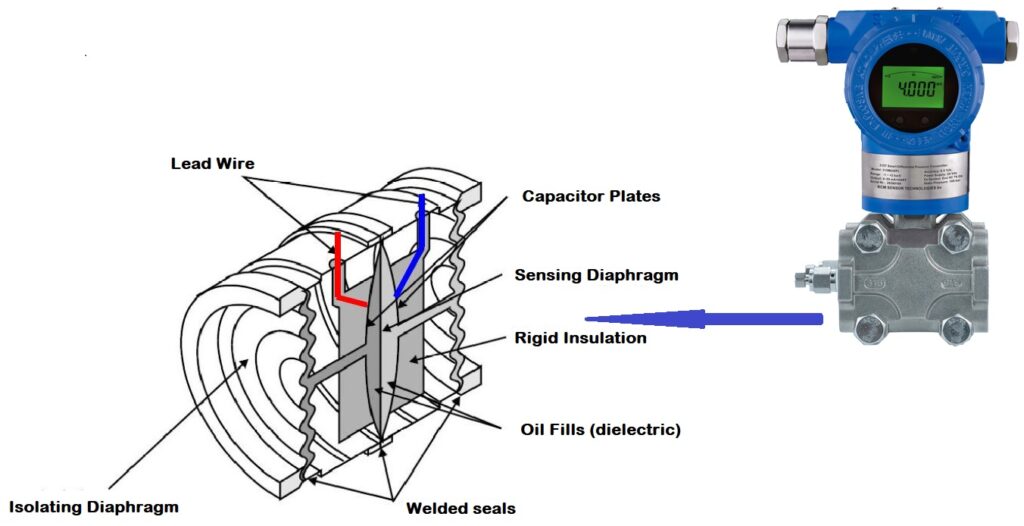

4. Differential pressure transmitter

Differential pressure transmitter has two sensing diaphragms and can measure the difference between two pressures. Differential pressure transmitters will produce an o/p signal on behalf of calibrated pressure range. These devices are commonly used in monitoring various industrial processes.

Pressure transmitter Working principle

Pressure transmitters convert mechanical pressure into an analog electrical signal. Pressure measurement is based on capturing changes in voltage. The pressure on the pressure transmitter acts as a force on the diaphragm – depending on the pressure applied the diaphragm either expands or contracts, and the resistance value changes accordingly. The value is then transmitted as an electrical signal. When a certain change of pressure occurs, pressure transmitters can be used to inform their users that something needs attention.

Capacitive pressure transmitter Working Principle

Capacitive pressure Transmitter works on parallel plate capacitor principle. When pressure acts directly on the surface of the measuring diaphragm, the diaphragm produces a small deformation. The high-precision circuit on the measuring diaphragm converts this small distortion into a highly linear voltage proportional to the pressure and proportional to the excitation voltage signal, and then use a dedicated chip to convert this voltage signal into an industry standard 4-20mA current signal or 1-5V voltage signal.

Diffused Silicon Pressure Transmitter Working Principle

The pressure of the measured medium acts directly on the sensor’s diaphragm (usually a 316L diaphragm), causing the diaphragm to generate a subtle displacement proportional to the pressure of the medium, changing the resistance value of the sensor, and detecting the Wheatstone circuit. This changes, and converts and outputs a standard measurement signal corresponding to this pressure.

Monocrystalline Silicon Pressure Transmitter Working Principle

Piezoresistive pressure sensors are manufactured using the piezoresistive effect of single crystal silicon. the elastic element is Single crystal silicon wafer . When the pressure changes, the single crystal silicon generates stress, so that the stress resistance directly exerted on it produces a change in proportion to the measured pressure, and then the corresponding voltage output signal is received by the bridge circuit.

Potentiometer Pressure Transmitter Working Principle

The most commonly used strain gauges are pressure transmitter metal resistance strain gauges and semiconductor strain gauges. Metal Resistance Strain Gauge is a kind of sensitive instrument which converts the strain change on the test piece into an electric signal. There are two types of wire strain gauge and metal foil strain gauge. Usually the strain gauge is tightly bonded to the mechanical strain matrix by means of a special adhesive. When the matrix is subjected to a strain change, the resistance strain gauge also deforms, causing the resistance value of the strain gauge to change, so that the voltage applied to the resistor changes. Potentiometer pressure transmitters are relatively rare on the market.

Sapphire pressure transmitter Working principle

The sapphire pressure transmitter uses the stress resistance working principle, adopts high-precision silicon-sapphire sensitive components, and converts the pressure signal into a standard electrical signal through a dedicated amplifier circuit.

Sputtering Film Pressure Transmitter Working Principle

The sputtering pressure sensitive element is manufactured by microelectronics technology, which forms a firm and stable Wheatstone bridge on the surface of the elastic stainless steel diaphragm. When the pressure of the measured medium acts on the elastic stainless steel diaphragm, the Wheatstone bridge on the other hand generates an electrical output signal proportional to the pressure. Because of its good impact resistance, sputtered films are often used in occasions that frequently have pressure impact, such as hydraulic equipment.

Output Of Pressure transmitter

Pressure transducers are generally available with three types of electrical output; millivolt, amplified voltage and 4-20mA. Below is a summary of the outputs and when they are best used.

(a). Millivolt Output Pressure Transducers

Transducers with millivolt output are normally the most economical pressure transducers. The output of the millivolt transducer is nominally around 30mV. The actual output is directly proportional to the pressure transducer input power or excitation. the output signal is so low, the transducer should not be located in an electrically noisy environment. The distances between the transducer and the readout instrument should also be kept relatively short.

(b). Voltage Output Pressure Transducers

The output is normally 0-5Vdc or 0-10Vdc. Although model specific, the output of the transducer is not normally a direct function of excitation. This means unregulated power supplies are often sufficient as long as they fall within a specified power range. Because they have a higher level output these transducers are not as susceptible to electrical noise as milli volt transducers and can therefore be used in much more industrial environments.

(c). 4-20 mA Output Pressure Transducers

These types of transducers are also known as pressure transmitters. Since a 4-20mA signal is least affected by electrical noise and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances. It is not uncommon to use these transducers in applications where the lead wire must be 1000 feet or more.

Selection of pressure Transmitter

There are many points for selecting a pressure transmitter, keeping in mind that the new transmitter should be installed. some points are given below-

1. Application and measurement type

Common type of pressure measurement include: Absolute, gauge, differential, vacuum. The application will determine the most appropriate measurement type.

2. Pressure range

Probably the single most important decision in selecting a pressure transducer is the range. One must keep in mind two conflicting considerations:

1. The instrument’s accuracy and its protection from over pressure. From an accuracy point of view, the range of a transmitter should be low (normal operating pressure at around the middle of the range), so that error, usually a percentage of full scale, is minimized.

2. On the other hand, one must always consider the consequences of over pressure damage due to operating errors, faulty design (water hammer), or failure to isolate the instrument during pressure-testing and start-up. Therefore, it is important to specify not only the required range, but also the amount of over pressure protection needed.

3. Process media

The process fluid that is going to be measured.

4. Temperature range and installation environment

Extremes in temperature or vibration will limit what transmitters will function properly. For temperature extremes, thin-film technology is superior. The extreme temperatures also create errors in the output of the transducer. The error is often expressed in percent full scale over 1°C (%FS/°C).

5. Accuracy

Pressure gauges come in many different accuracies. Accuracy of common pressure transducers could range from 0.5% to 0.05 % of the full-scale output. Higher accuracies are desired when it is necessary to read very low pressures for critically demanding applications.

6. Output

There are several types of outputs for pressure transducers. These include: mV output, amplified voltage output, mA output.

Pressure Transmitter Calibration – click here for step of Pressure transmitter calibration

Read Also