Table of Contents

Float Type Level switch | Water Level float switch | Float level switch

Float Type Level switch working principle is given below. Basically float level switches are general liquid level switches, and are used to detect liquids. These level switches have been used in various locations where liquid levels must be detected. A mechanical switch known as a float level switch floats on top of a medium and moves up or down when the medium rises or dips. They frequently work with alarms, pumps, and valves. Float switches can be utilised with a variety of media and are a reliable and affordable level switch.

Working principle of float type level switch | Functioning of flat level switch

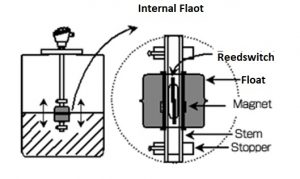

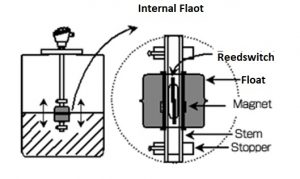

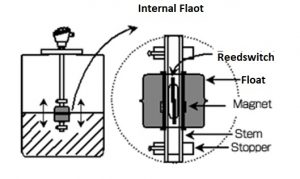

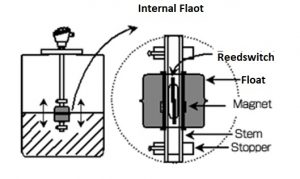

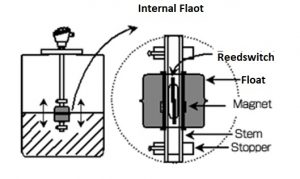

The principle of float type level meter is that a float moves up and down due to buoyancy. A reed switch in a stem is actuated by a magnet in the float, and gives a digital output as signal. A float will be pushed up or down as the level rises and falls. The float may be fastened to a hinge that glides along a shaft or opens and closes. There are several ways to detect the position of the float along the shaft or the opening and closing of the hinge. A permanent magnet will be built into the float of a sliding float level switch that is mounted vertically and slides up and down the shaft. Along the shaft, a magnetic reed switch is placed at the necessary level set point. The level switch circuit is opened or closed depending on whether the float passes over the reed switch. A microswitch or a magnetic reed switch that is actuated by an actuator or lever attached to the float will be included in a horizontal mount hinged type float level switch. With the addition of additional switches, a shaft-type float switch can manage the liquid level for a number of distinct processes that are engaged at various levels. Material compatibility must be taken into account because a float level switch will come into direct contact with the liquid being measured.

Construction of float level switch

A float switch’s design involves a hollow body that houses a switch or sensor, typically a reed switch with an internal magnet. Due to gravity and the media level, the switch opens or closes. Float switches are programmed to activate when the level exceeds the predetermined limits. A linked device can be opened or closed by the switch by sending a signal to a mechanism.

Advantages of float type level switch

following are the advantages of float type level switch.

Various models are offered for bottom, side, or top entry mounting.

most affordable kind of liquid level switch.

Simple structure and design.

Not affected by variations in SG and density.

Some varieties can run without electricity.

Performance is unaffected by surface imperfections including bubbles, foaming, and ripples.

Operation will not be impacted by the fluid’s conductivity or dielectric constant.

It is possible to specify several materials for media compatibility.

Operating conditions are unaffected by vapours, condensation, or mist.

The buoyancy of the float will not be compromised by a vacuum or low pressure sealed tank.

Disadvantages of float level switch

Following are the the disadvantages of float level switch.

Moving components prone to congestion, deterioration, and damage.

Fouling may result in erratic movement or float actuation seizure.

Liquid contact is required for float actuation.

The float could move due to fluid turbulence.

The float may not be able to move if the fluid is thick or sticky.

routine maintenance to make sure nothing is impeding the movement of the float.

Side entrance type single point level switch.

Float assembly sticking out into the liquid, which causes obstruction, draws fouling, and causes hygienic cleaning problems.

Float level switch application

Following are the some application of float level switch.

Pump or valve control

The most typical application in the sector is likely the automatic opening and closing of a valve using two float switches. This setup can be used to drain a full tank or fill one that is running low in order to maintain a precise liquid level in tank.

High of low level alarm

Protecting against and alerting to a potential hazardous spill requires the use of a float switch to trigger tank level alarms. Tank overfilling can result in expensive damage, deadly chemical spills, and oil spills that endanger both the environment and personnel. A reliable, high-quality float switch with an audible and visual alarm can help businesses save time and money.

Heater Protection

Using a float switch can assist avoid hazardous situations and safeguard heaters and other equipment from serious damage. Immersion heaters are employed in a variety of settings to maintain a specific temperature or prevent the freezing of liquids. To make sure that the fluid level stays above the heating element, liquid level float switches are employed. The float switch may turn off the heater’s electricity if the level falls too low.

Read Also:-

Related Search:-

How to Measure Conductivity?

How to Measure Conductivity?

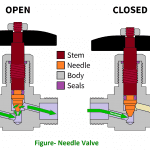

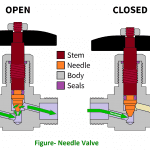

Control Valve Classification

Control Valve Classification

Working principle of electromechanical Pressure Switch

Working principle of electromechanical Pressure Switch

How to control boiler drum level

How to control boiler drum level

Displacer type level switch working principle

Displacer type level switch working principle