Table of Contents

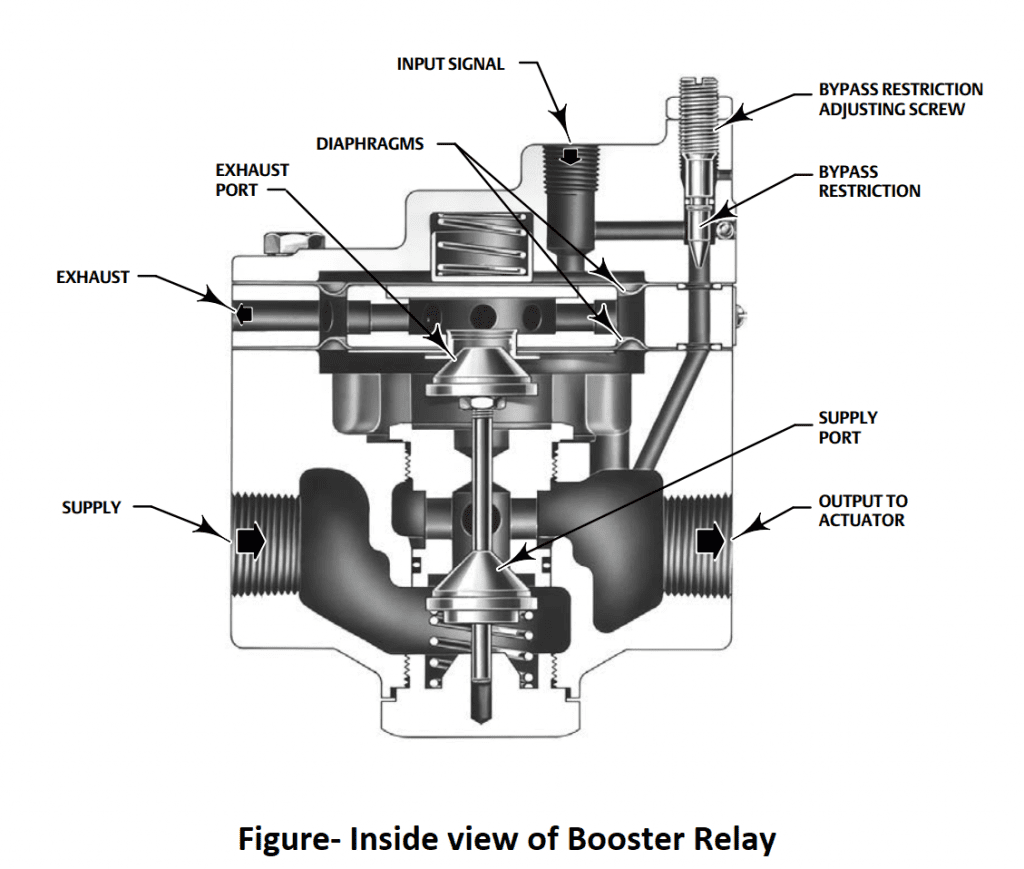

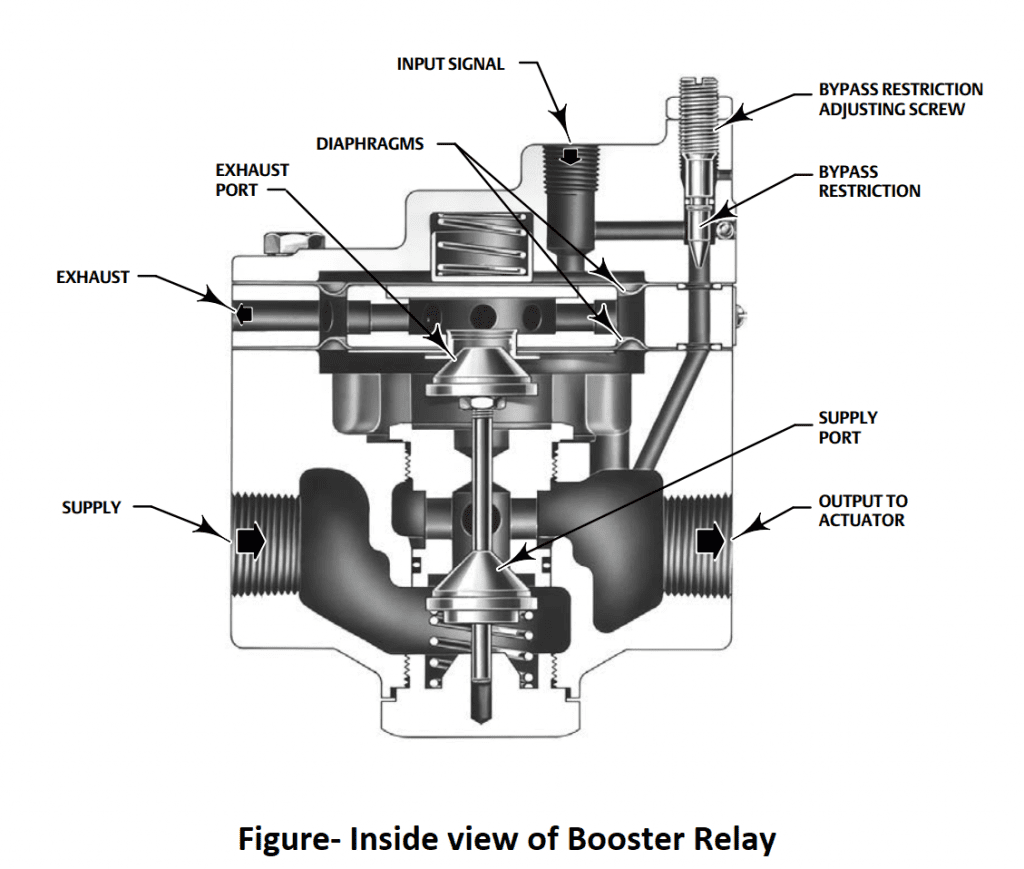

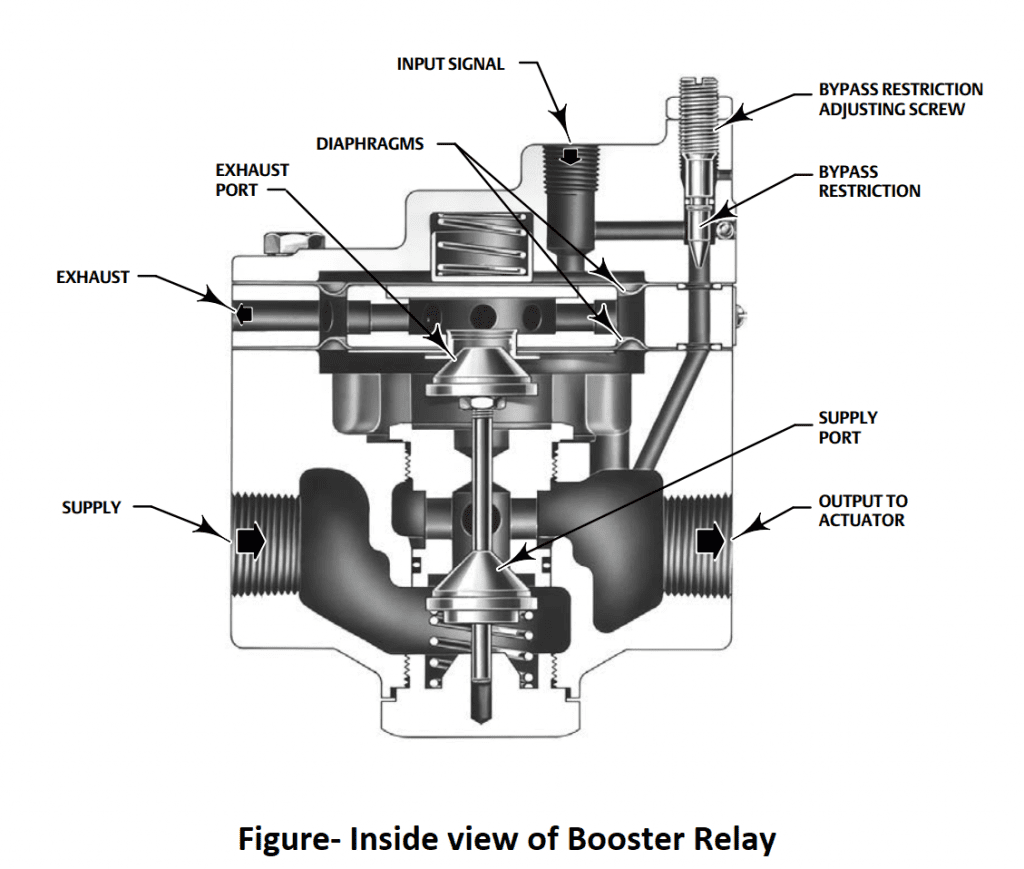

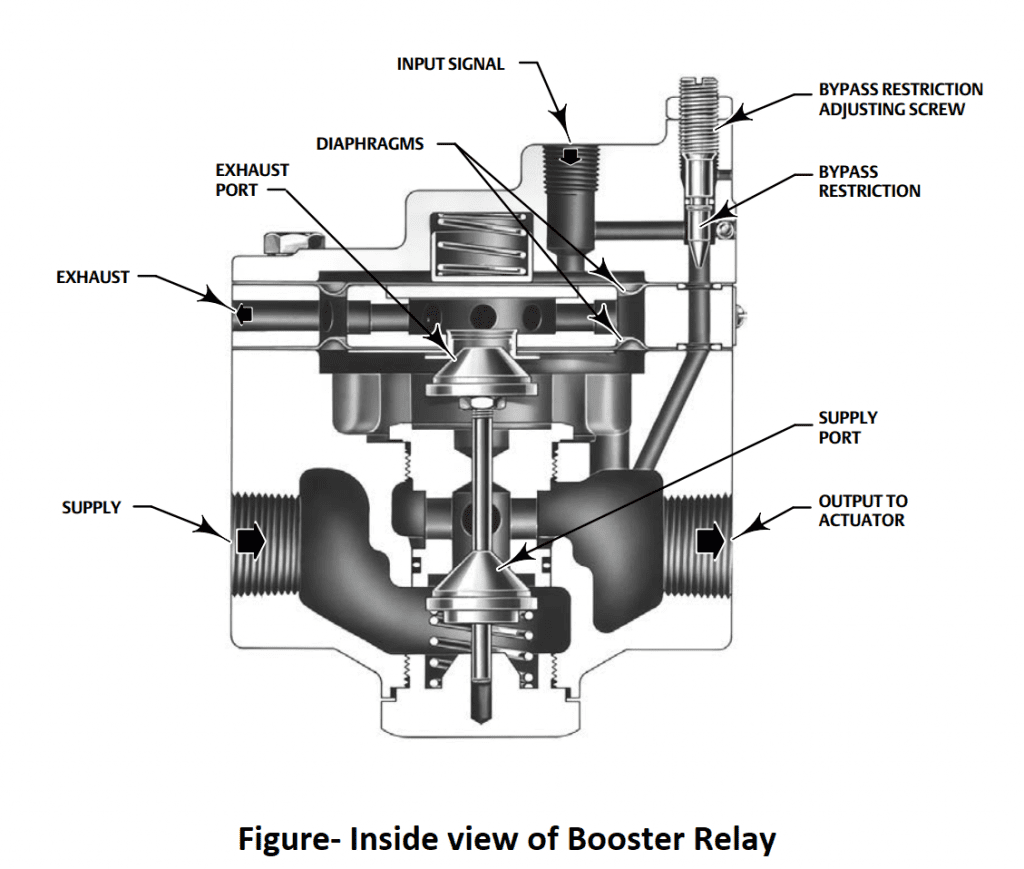

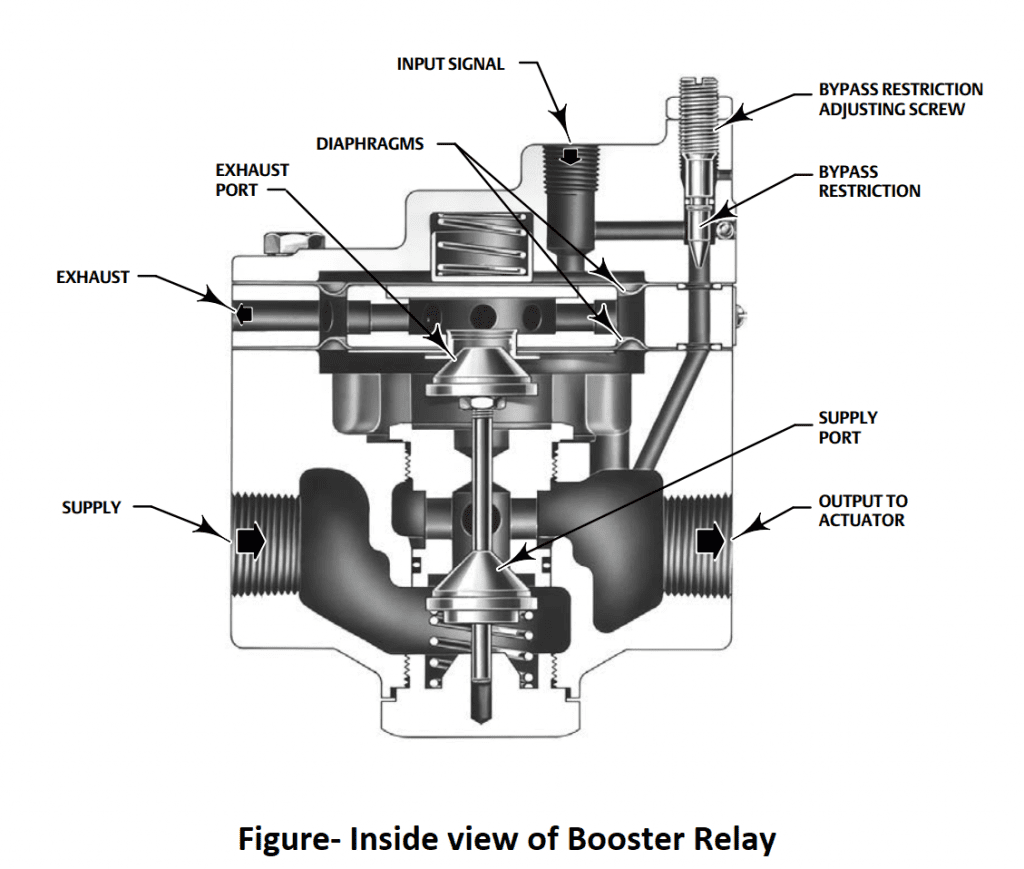

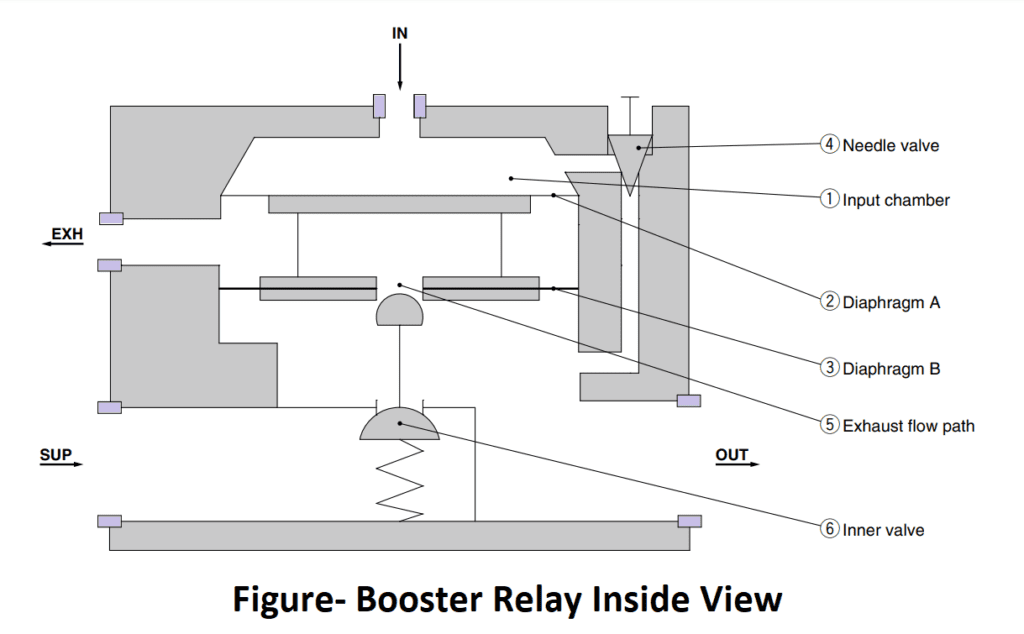

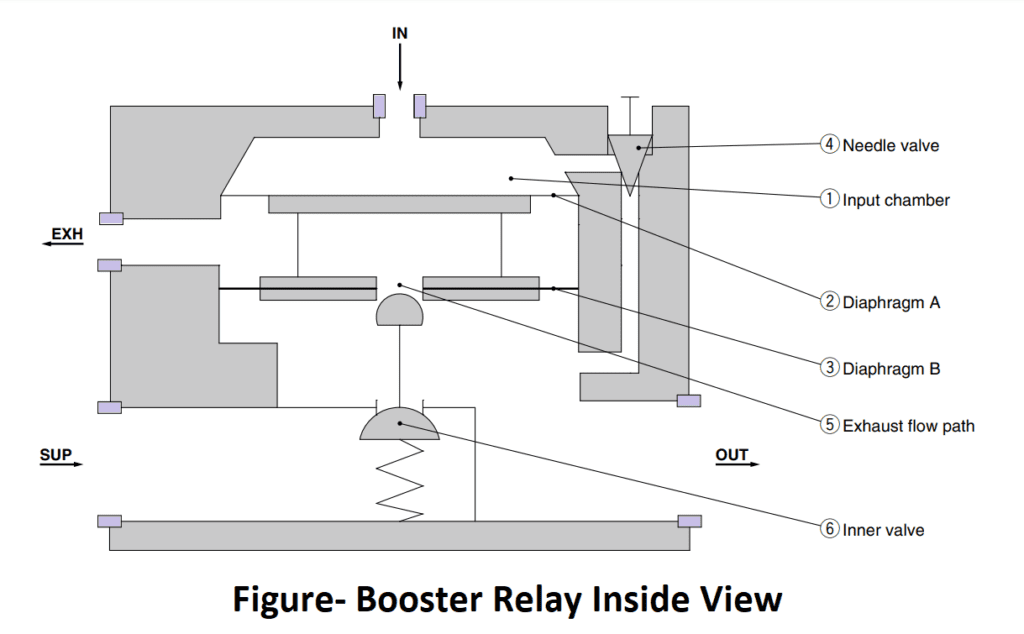

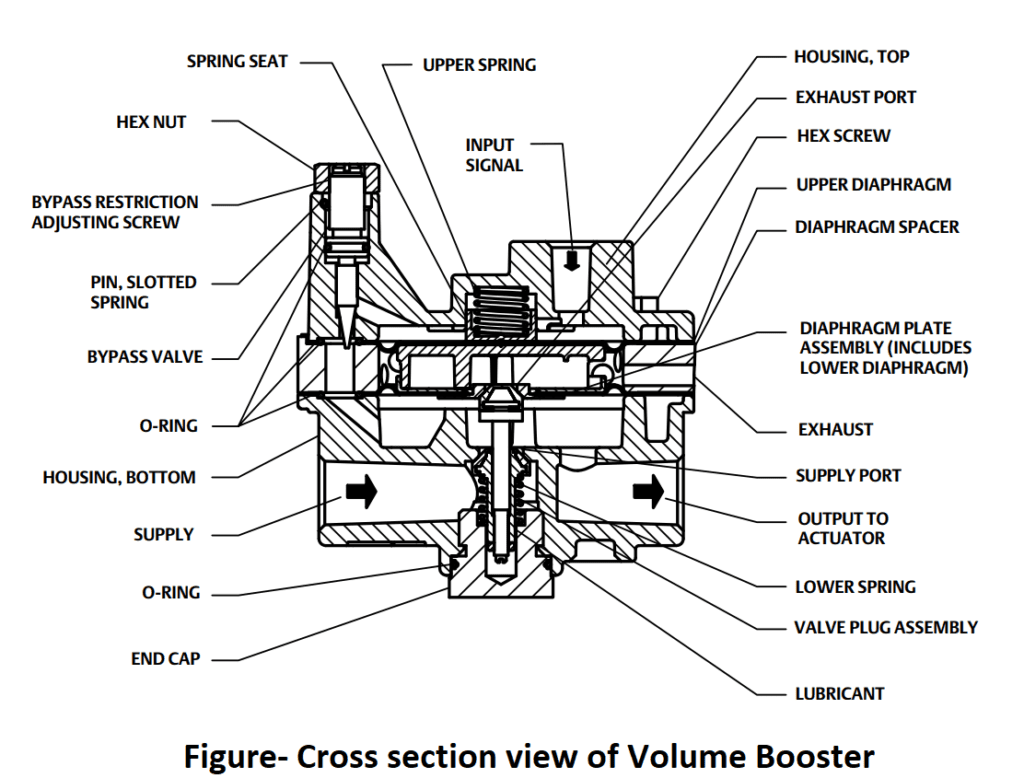

Booster relays (From SMC), sometimes called as volume boosters are pneumatic devices designed to reproduce a pneumatic pressure signal (1:1 ratio), but with far greater output flow capacity. Volume boosters are typically increase volume / flow of instrument air supply for faster control valve operation. A diagram of booster relay is shown below-

Working principle

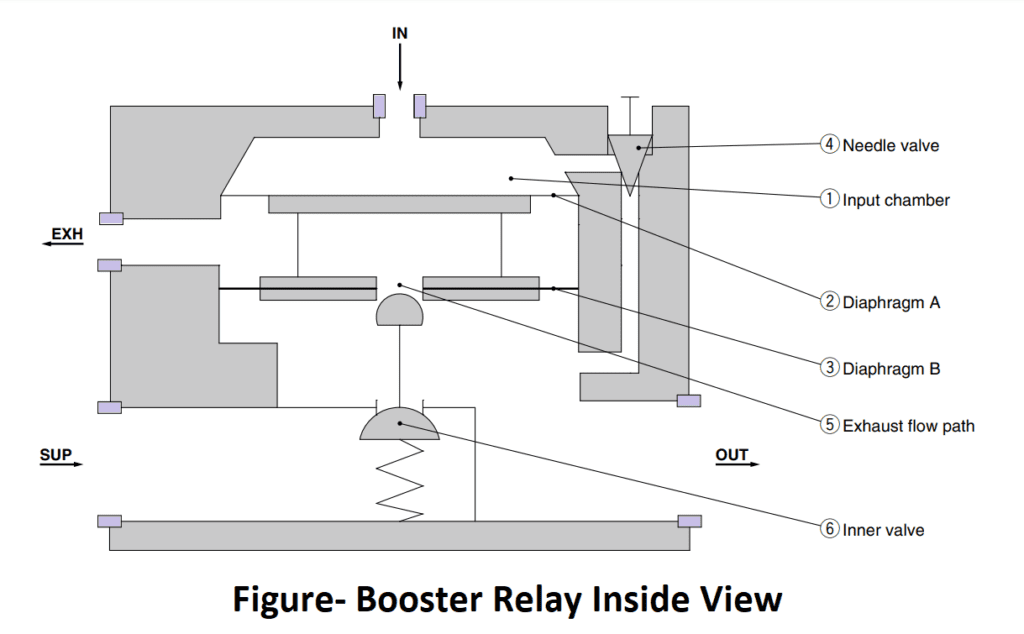

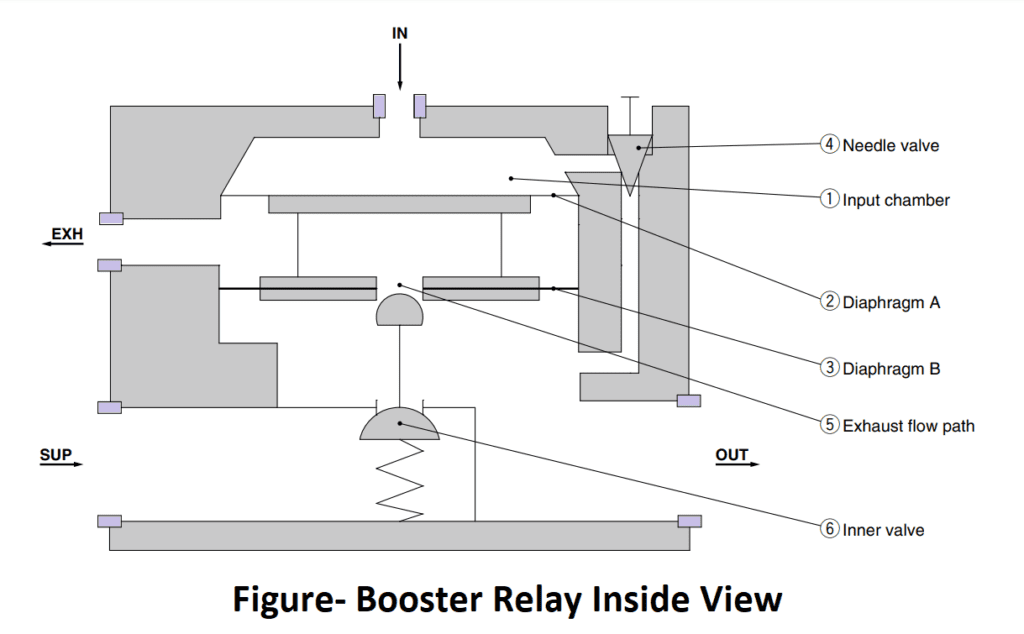

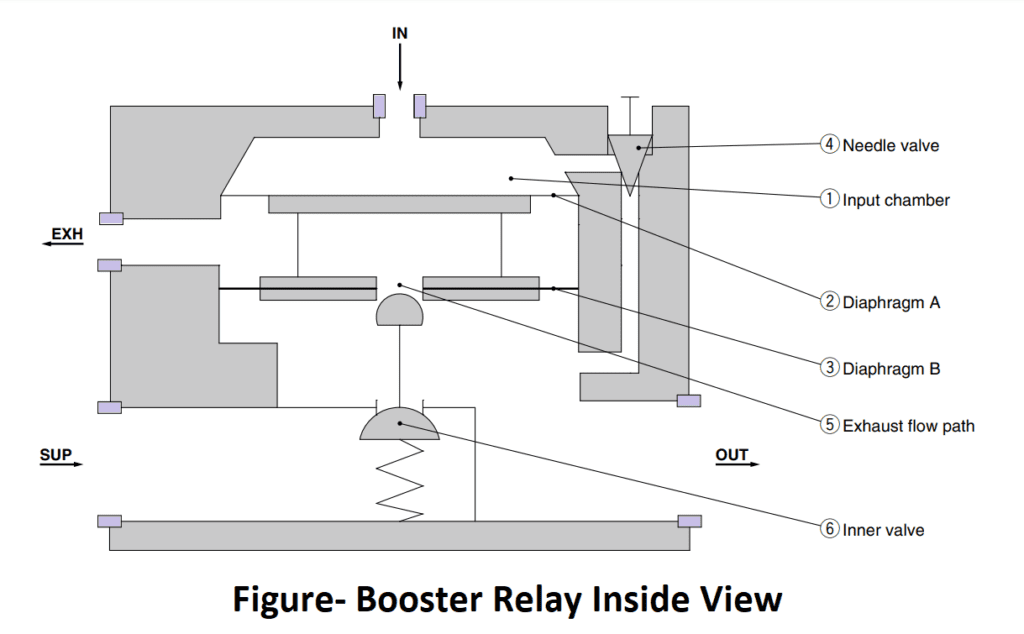

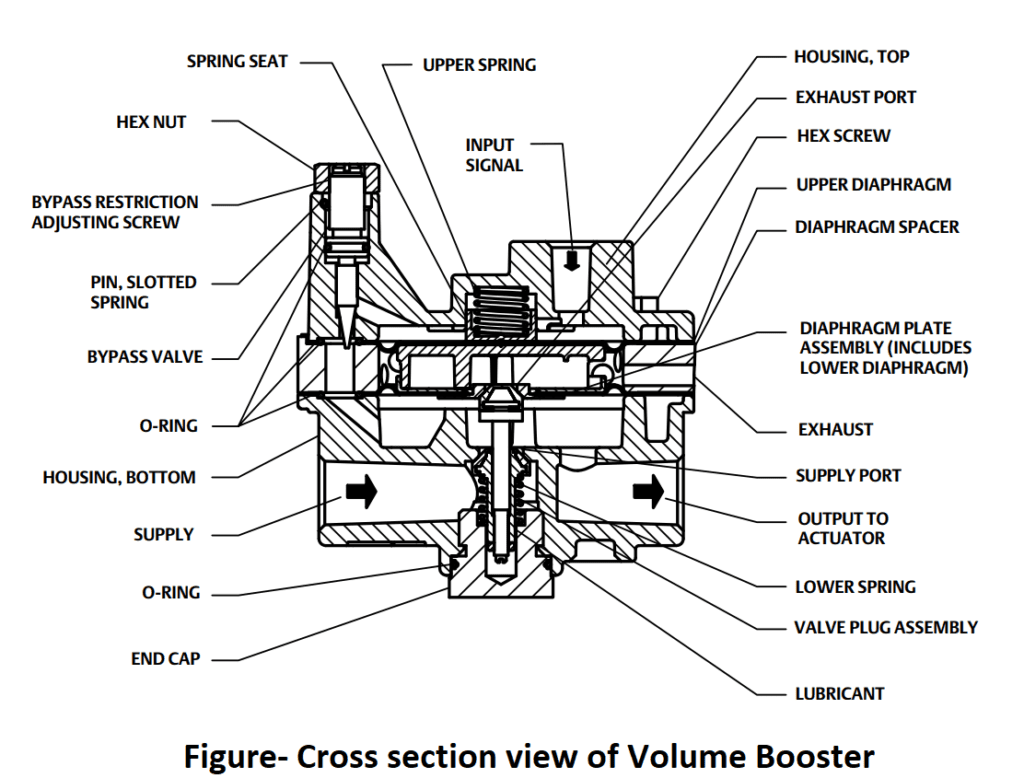

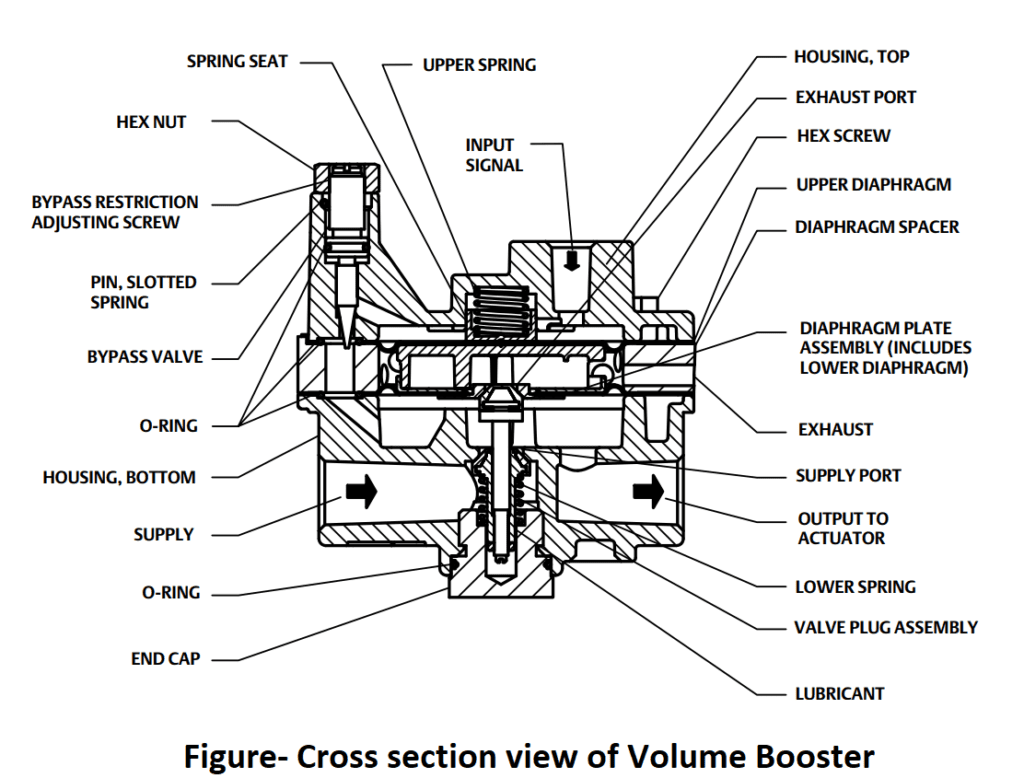

To understand working principle, an exploded diagram of booster relay is showing below-

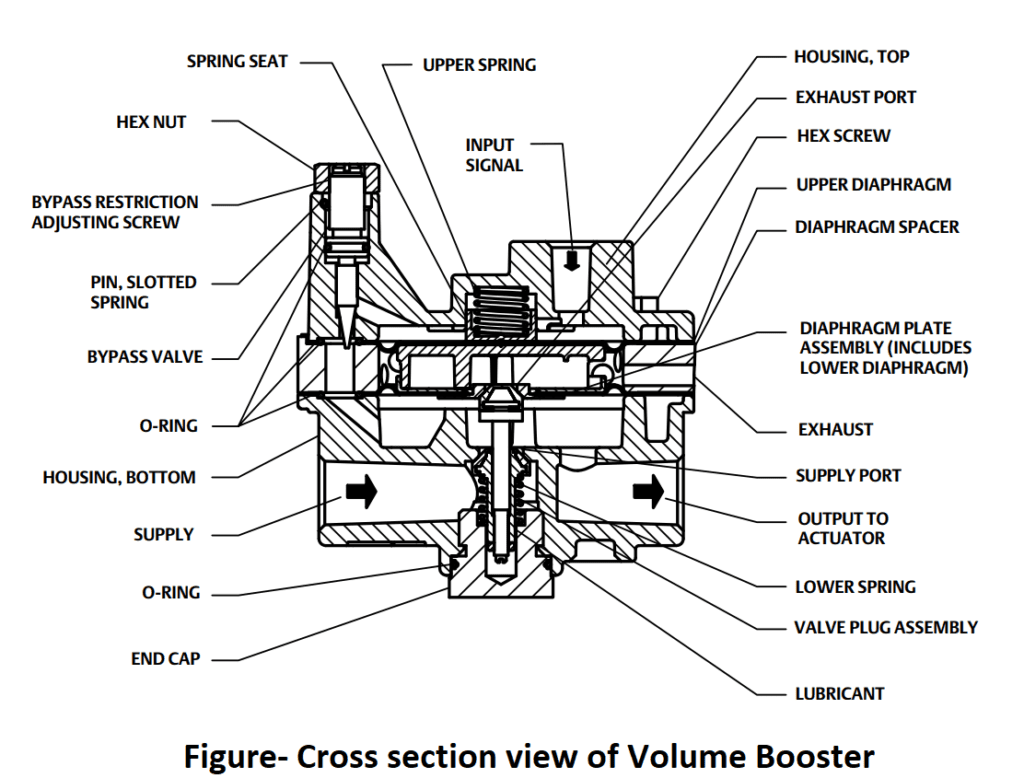

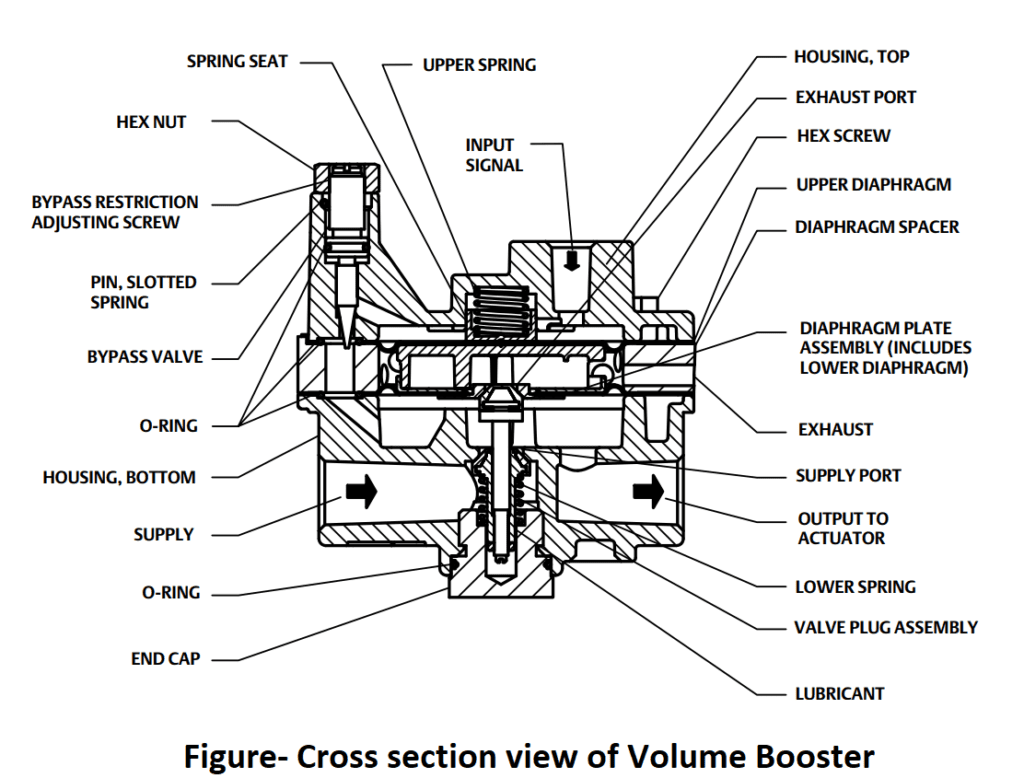

Refer to figures, when input signal pressure is applied to volume booster, diaphragm-A exerts a downward force on diaphragm B. When the force of the input chamber exceeds the force of diaphragm B, inner valve is depressed allowing air flow out the secondary supply port. On signal pressure exhaust, the supply valve closes and exhaust flow path is opened to allow exhaust of the secondary air supply to atmosphere. Input and output ports are connected by the needle valve. Adjustment ensures that exact equalization occurs between the signal and output supply. The above function allows a low volume signal to provide high volume output with pressure ratio remaining (1:1) for signal to output. Because of the bypass restriction, large input signal changes register on the booster input diaphragm sooner than in the actuator. A large, sudden change in input signal causes a pressure differential to exist between the input signal and the output of the booster. When this occurs, the diaphragms move to open either the supply port or the exhaust port, whichever action is required to reduce the differential. The port remains open until the difference between the booster input and output pressures returns to within the dead band limit of the booster.

Different parts showing in a volume booster are given below-

Main Features of booster relay

- Fast Response— Booster delivers the volume needed for rapid actuator stroking when large input changes suddenly occur.

- Adjustable Response—Integral bypass restriction tunes the booster response so that smooth actuator motion follows the slow signal changes.

- Efficient Operation—Soft seats provide tight shutoff to reduce unnecessary air consumption and eliminate saturation of positioner relays.

- Maintains Accuracy—Booster permits high actuator stroking speeds upon demand without degrading the positioner steady-state accuracy.

Read Also:-

Related Search:-

Displacer type level switch working principle

How Infra Red(IR) Gas analyzer Work

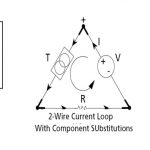

Fundamentals of 4-20 mA Current Loops

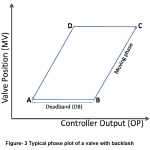

Control Valve performance parameters