Table of Contents

Optical level switch | Optical Liquid level switch

Optical level Switch Working principle is given below. Basically the optical level switch has many uses, especially in a wide range of machines to determine high or low levels of various fluids.The advantages of an optical level switch typically include their compact size, high reliability and relatively low cost.

Working Principle of optical level switch

An optical level switch works by emitting a beam of infrared light within a prism and measuring the amount of light received. When the measured fluid reaches the sensor the amount of emitted light received drops thus triggering the contacts. As the sensor is detecting the state between material covering or not covering the prism it can be used to detect the presence or absence of fluid.

Construction of optical level switch | Parts of optical level switch

The compact unit houses the infrared transmitter, the prism, the receiver and the electronics; there is also an external LED indicator to show the condition of the switch. The sensor requires a power supply of between 10-28 Volts Dc. The benefit of the modern optical sensor is that there are no moving parts that can retain material and get clogged up or damaged, simply fit and forget.

Applications of Optical level switch | Use of optical level switch

Almost every sort of liquid, whether it is based on oil or water, can be detected by an optical liquid level switch. Leak detection and single point level control are the two basic functions of these level switches (maximum or minimum).

These switches serve to avoid numerous costly and hazardous scenarios for a relatively little cost. The smallest amounts of liquid can be detected in leak detection applications to prevent the loss of priceless fluids, run-dry situations, expensive damage, loss of service, and downtime. They are utilised for automatic refilling for low-level and high-level liquid level procedures in level control applications. Overspill or run-dry problems can be avoided by optical level switches.

In level control and detection applications, a tank or vessel’s liquid level is continuously changed over time. To avoid costly damage, flooding, or run-dry scenarios, it is essential to have a level control monitoring solution in place that can detect when failure happens or when the level is dangerously high or low.

Many businesses utilise the optical level switch as a level indication. Industrial, domestic, medical, maritime, aviation, and transportation are examples of industries.

Advantages of optical liquid level switch

Simple, little, and sturdy

Nothing that moves.

Solid-state electronics that are built in.

Simple to uninstall, clean, and reinstall.

LED switch signalling.

Read Also:-

Related Search:-

Solenoid Operated Valve

Solenoid Operated Valve

Control Valve Problems

Control Valve Problems

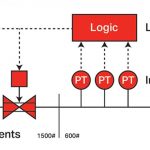

Two out of three (2oo3) Logic

Two out of three (2oo3) Logic

pH Measurement

pH Measurement

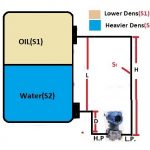

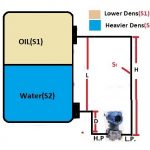

Interface level measurement using Differential Pressure Transmitter (DPT)

Interface level measurement using Differential Pressure Transmitter (DPT)