Table of Contents

conductivity type level switch

Conductivity level switch is sensor with an electrical contact output at a specific liquid level. Applications include ponds, reservoirs, sumps, pharmaceuticals, closed vessels and open tanks. The level of all conductive mediums can be controlled using conductive level switches. In addition to permanent rigid rods, removable rigid rods, and pendular electrodes connected to the housing via cables are all options for conductive level switches. Both alarm point detection and on/off pump valve control applications are suitable for these switches. The operation requires no maintenance, and installation is simple. The level-control electrode and the reference electrode’s electrical resistance vary, the probes work through the variation of this electrical resistance.

Working Principle of conductivity type level switch

When the medium covers their electrodes, conductivity level switches can detect the level of medium in the tank.

The reference electrode can be a tank wall that conducts electricity. An additional electrode is needed as a reference if the tank is constructed out of plastic, concrete, or any other nonconductive material.

A low AC Voltage is connected via the control unit between the sensing electrodes and reference electrodes (tank wall in case of metallic tanks) As soon as the conductive material touches the electrodes, a low AC current starts to flow which operates the relay in the control unit and gives a digital output. The output of the liquid level switch can then be used by other instruments to open a valve, turn on a pump, turn on a warning bulb, or activate an auditory alarm.

How does a Conductive Level switch work

A magnetic field travels through the relay’s laminated ferrous core when line voltage energises the primary coil. When there is no liquid covering the probe circuit and the secondary circuit is open, the magnetic “circuit” in the core is completed by the magnetic field passing effortlessly through the centre of the secondary coil. The armature won’t be drawn to the core now that the magnetic circuit has been finished.

However, when a circuit is finished by the liquid level rising to come in contact with both probes, the secondary coil’s consequent current “bucks” the magnetic flux through its centre, sending more magnetic flux to the end poles instead, where it draws the ferrous armature toward the core frame.

Advantages of Conductivity level switch

Conductivity level switches have the following advantages.

Conductive level switches are easy to install and operate.

Conductive level switches are rugged construction.

conductive level switch are not costly.

They dont required any calibration.

They dont have any moving parts.

Disadvantages of Conductivity level switch

When a probe is near fluid, some types can cause sparks.

Pitting, plating, or fouling caused by the corrosion of probe tips as a result of residue, electrolysis, or chemical corrosion.

Thick or sticky medium will leave the probe with a coating that will act as an insulating layer and cause problems.

when utilised with less conductive liquids, a greater voltage level across probes is necessary.

Probe sticking out into liquid can restrict flow, invite fouling, and cause other hygienic hygiene problems.

Read Also:-

Remote seal DP transmitter Calibration

Related Search:-

Paddle level switch working principle

Paddle level switch working principle

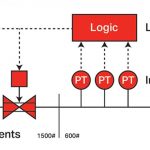

Two out of three (2oo3) Logic

Two out of three (2oo3) Logic

Control Valve Problems

Control Valve Problems

Proximity Switch

Proximity Switch

How to check linearity of vibration probe(Axial&radial)

How to check linearity of vibration probe(Axial&radial)