Table of Contents

Load cells are the devices used to measure the force through indirect methods. There are basically 4 categorized load cell types based on their working principle as mentioned as-

- Pneumatic load cell

- Hydraulic load cell

- Strain gauge load cell

- Piezoelectric load cell

Pneumatic load cell

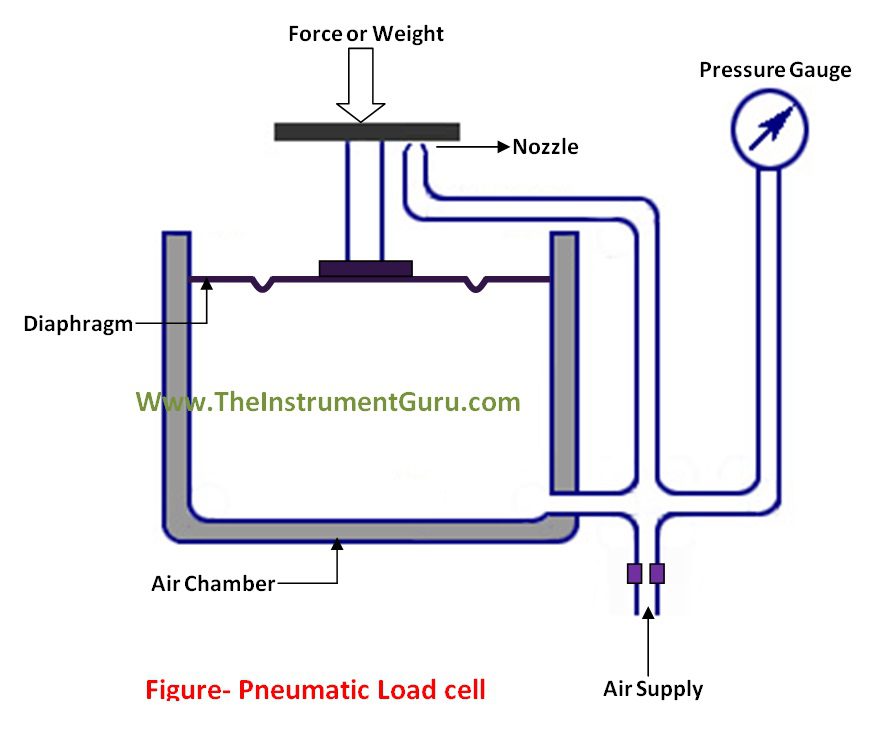

The pneumatic load cell is designed to manage the balancing pressure automatically. The air pressure is applied to one end of the diaphragm and then released through the nozzle. The pressure inside the load cell is measured using a pressure gauge attached to the load cell. The airflow through the nozzle and the pressure inside the chamber are both affected by the diaphragm’s deflection. The force-balance principle works in pneumatic load cells. Multiple dampener chambers are used in these systems to provide greater accuracy than hydraulic devices. Pneumatic load cell is used to measure force up to (2.5 * 103) kg force. To understand the working of pneumatic load cell, a diagram showing arrangement is given below-

Hydraulic load cell

Hydraulic load cell converts applied force or load to hydraulic pressure. The cell uses a conventional piston and cylinder arrangement with the piston housed in an elastic diaphragm. The piston does not actually come into contact with the load cell. The load cell chamber is completely filled with hydraulic oil. When load is applied to the piston, the oil pressure increases as a result of the movement of the piston and diaphragm. This pressure is then transmitted to a hydraulic pressure gauge that can be calibrated to a scale of applied load or force. Since the cell has no electrical components, it is ideal for use in hazardous areas. Typical hydraulic load cell application includes tank, bin and hopper weighing. Hydraulic load cell can measure force upto 2.5MN force. A diagram showing the hydraulic load cell arrangement is shown below-

Strain gauge load cell

Strain gauge load cells are the most common load cell types widely used in industries. They don’t convert load or force into differential pressure as like in hydraulic and pneumatic designs. Strain gauge load cell operates through producing changes in electrical resistance in strain gauge, when load is applied. Inside each strain gauge load cell is at least one strain gauge device. In a load cell strain gauge acts as a secondary transducer. The strain gauge functions on the elastic properties of resistance wire that is- “when a wire is stretched, its length increases and cross section decreases hence resistance of the wire will increase, and when compressed resulting into the resistance of the wire will decrease. Here, change in resistance produces change in form of voltage or current, when gauge is connected to bridge circuits thus the amount of force delivered to the cell is proportional to the change in voltage, therefore the amount of force can be calculated from the load cell’s output or an scale can be calibrated directly to measure physical quantity such as force, load or weight. A diagram to illustrate its working principle is shown below-

Piezoelectric load cell

Piezoelectric load cell works on the principle of piezo-electric effect that states “when piezo electric crystals such as quartz, tourmaline, Rochelle salt and topaz etc. are compressed or stressed, resulting its deformation, a small voltage is produced across its surfaces; this property of crystal is called as piezo electric effect sometimes known as piezoelectricity.” Since the piezoelectric effect is dynamic that’s why such load cells are useful for dynamic/frequent measurements of force. In most applications, piezo load cell is used in the dynamic loading conditions, where strain gauge load cells can fail with high dynamic loading cycles. Using a charge amplifier (i.e. load cell amplifier), smaller voltage are amplified to a certain level for detection purpose. A diagram showing piezo load cell (kistler load cell- make) is shown below-

Based on different characteristics and application accordingly, several other load cell types are as mentioned below-

- Digital Load Cell

- Single Point load cells

- S-type load cells

- Ring type load cell

- tension load cell

- compression load cell

- miniature compression load cell

- beam load cell

- s beam load cell

- shear beam load cell

- Planar Beam load cells

- Dual Shear Beam load cells

- Bending Beam load cells

- double ended beam load cell

- single ended shear beam load cell

To read more about other related topics click on individual links here-

- S Type Load Cell

- Load cell wiring and calibration

- HBM load cell

- What is a Load cell?

- What is strain gauge?

- Types of strain gauges

- What is Gauge Factor?