Table of Contents

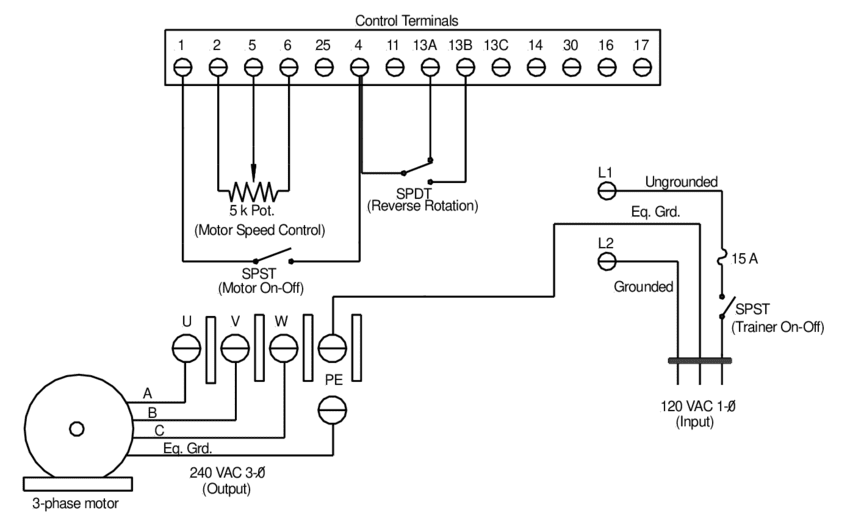

Control wiring and power wiring are used in the industry to drive a motor. The control drawing contains the logic to run the motor. Low voltage is required for control drawing. In the power drawing it is known from which terminal the power is going to run the motor.

Control wiring

Control wiring, as its name suggests, has the main purpose of transmitting electricity to be used for control purposes. The control wiring carries a low level of current, as not much current is required for control purposes such as activating small coil relays or feeding into PLC input cards. The control wiring is not necessarily low voltage, although most modern systems use 24 V DC or something similar, or some form of low voltage data signaling.

Industrial control wiring used to be almost all 120V AC (in the US) and there are many 220V AC control systems around. These have largely disappeared due to safety concerns and ease of maintenance.

Because control wiring carries small amounts of current, the wire gauge of its conductors can be small, and the insulation must be adequate for the voltage level of the control signal.

Power wiring

Power wiring, as the name suggests, has the primary purpose of transmitting electrical power. Because of this the size of the conductors (usually copper) must be large enough to carry the desired intensity. Power wiring doesn’t have to be high voltage. The wires coming out of your car battery are power wires, because they carry a substantial amount of electrical power, but they are only (nominally) 12 volts DC.

How are they different?

To transfer power we use power wiring. If we look at the power distribution panel in any industry, we can see power wiring and control wiring. We can see an incoming bus bar and power will be connected to MCCB and then it will be distributed so all these wirings are power wirings. In the same panel we can see a multifunction meter, this is a control wiring. An example of this would be PLC control panel and we can see both power wiring and control wiring in it but control wiring will be more in this, power wiring in PLC control panel starts from incoming and a MCB will be connected after that it is converted to 24V DC It will be connected to a PLC and then the input and output control of the PLC connection is done by wiring. We use high gauge wires for power wiring but in case of control wiring we use low gauge wires. The connection of field devices to the control system or sensor wiring is all control wiring and the cables we have used for this will be shielded cables. Power cables have very few cores as compared to control cables. The PLC input wiring will be made up of many feedbacks from sensors and other field devices and all of these wiring will be the control wiring.

Star delta wiring

The star-delta starter is made up of three contactors, a timer and a thermal overload relay. The image below represents the power and control wiring of a star-delta starter.

There are mainly four figures in a star-delta starter:

1. OFF STATE ⇒ This is the OFF state of the starter, all contactors are in the OFF position.

2. Star State ⇒ In this state the main and star contactors are closed and the delta contactor is open. The motor is connected to the star.

3. Open State ⇒ This state is the transition state from star to delta. Only the main contactor is closed, both star and delta contactors are open. There is voltage at only one end of the motor winding. The rotor is still turning.

4. Delta State ⇒ Main and Delta contactors are closed and Star contactor is open. Motor is running with full line voltage and full load speed.

The star and delta are electrically interconnected as shown in the figure below.

Read Also

- Wiring diagram | house wiring diagram | staircase wiring diagram

- What is Rupture Disc ? | Types and Applications.

- Neutral wire | Why neutral wire is so important?