Table of Contents

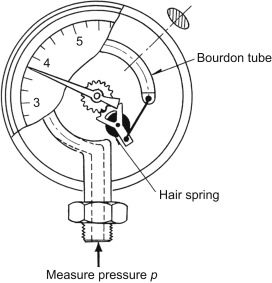

Pressure sensing elements; Diaphragm, Bellows, capsule, Bourdon tube, spiral and helix are a full range of mechanical devices that change shape when pressure is applied. These are called elastic deformation pressure sensing elements. Each of them is adapted to a different range of pressure. The table on the following page lists these pressure sensing elements, with their lower and upper limits expressed in inches of water or pounds per square inch. In a typical industrial pressure gauge with a Bourdon tube pressure element. Pressure enters the Bourdon tube, causing it to open. As the tip of the Bourdon tube opens, it rotates a lever arm, which is connected by gears to pointer. A spiral spring is attached to the pointer to eliminate any “play” in the linkage.

Recording pressure gauges are often used in industry. Typically, they use elastic deformation elements, with spiral and helix being the most common. In recent years it has become necessary to develop pressure measuring devices that provide electric generation. In some of these, the elastic deformation elements listed above are used, and electrical equipment is connected to them. As the element expands or contracts, an electrical characteristic, such as resistance, varies. For each unit of change in the size of the pressure sensing element, there must be one unit change of the electrical variable. A device called a transducer converts one form of energy into another. Most of these power transducers are used in bridge type circuits such as Used for resistance thermometers.

Bourdon Tube Elements

The most common type of pressure element we use here is the Bourdon that is the most efficient positive way of transmitting mechanical motion. Moving parts are designed and protected to reduce friction and extend wear life. A unique curved tail section and captive link facilitates calibration. It is desirable that each movement be ultrasonically cleaned and lubricated to resist the wear associated with high frequency vibration or pulsation.

Parts of bourdon Tube Element

There are some important part of pressure sensing element that is given below-

-

Dial

The aluminum dial has highly legible black markings on a white background. Baked on a clear, acrylic coating, the marking is applied over, extremely durable that won’t corrode and allows the dial to be cleaned without damage.

-

Pointer

The balance indicating indicator allows for easy reading as well as easy adjustment. Easily accessible from the front of the gauge, the micrometer adjustment allows the pointer to be changed without removing it from the shaft.

-

Windows/Glass

The standard material for windows is shatter-proof glass, ordinary glass, acrylic windows (more resistant than glass windows to impact it shatter), (will not fact into as many pieces as ordinary glass).

-

Rings

The rings that surround the window can be threaded, bayonet (cam), hinged or snap designs depending on the case type. All windows must have gaskets to protect internal mechanisms from weather, dust and fumes

-

Spiral Elements

It is also a modification of Bourdon element and finds wider uses in industrial applications. It consists of a thin welled tube, flattened at both ends, and it formed into a spiral. The spiral arrangement provides large movement of free end; thus is useful in recorders. The range is 0.7 to 260 kg/cm2 No sector or pinions required and hence discrepancies due to friction are reduced.

-

Helical elements

In principle it is like bourdon element, but is wound in the form of helix to increase tip movement. This design transmits only the circular component of the movement to the pen arm, which is directly proportional to the change in pressure. This is widely used in recording type of instrument as well.

Bellows

These are other of the elastic elements used as pressure transducers. These are made of alloys that are ductile, have high strength and have little hysteresis effect on their properties when used for a long time. Bellows are used in two forms. In one arrangement pressure is applied to one side of the bellows and the resultant defect is balanced by a spring. This arrangement indicates the gauge pressure. In another differential arrangement, differential pressure can also be indicated. In such a device, one pressure is applied inside one sealed bellow while another pressure is applied inside another sealed bellow. By appropriate linkage and calibration of the scale, the pressure difference is represented by a pointer on the scale.

Hysteresis and zero shift are somewhat more problems with this type of element than most others. Resisting spring – very sensitive element than Bourdon element. Greater applications in the lower, including draft and intermediate ranges. It is composed of a metal bellows enclosed in a shell which is attached to pressure source. The pressure acting on the outside of the bellows compresses the bellows and moves its free end against the opposing force of the spring, a rod resting on the bellows transmits the motion to the pointer. This gauge with suitable arrangement can be used to measure the pressure difference as absolute pressure.

Phosphor bronze is a commonly used material for bellows and the spring is carefully heat-treated metal. The range is 2500 mm of water to 3.5 kg/cm2 gauge or vacuum between 260 to 750 mm of mercury.

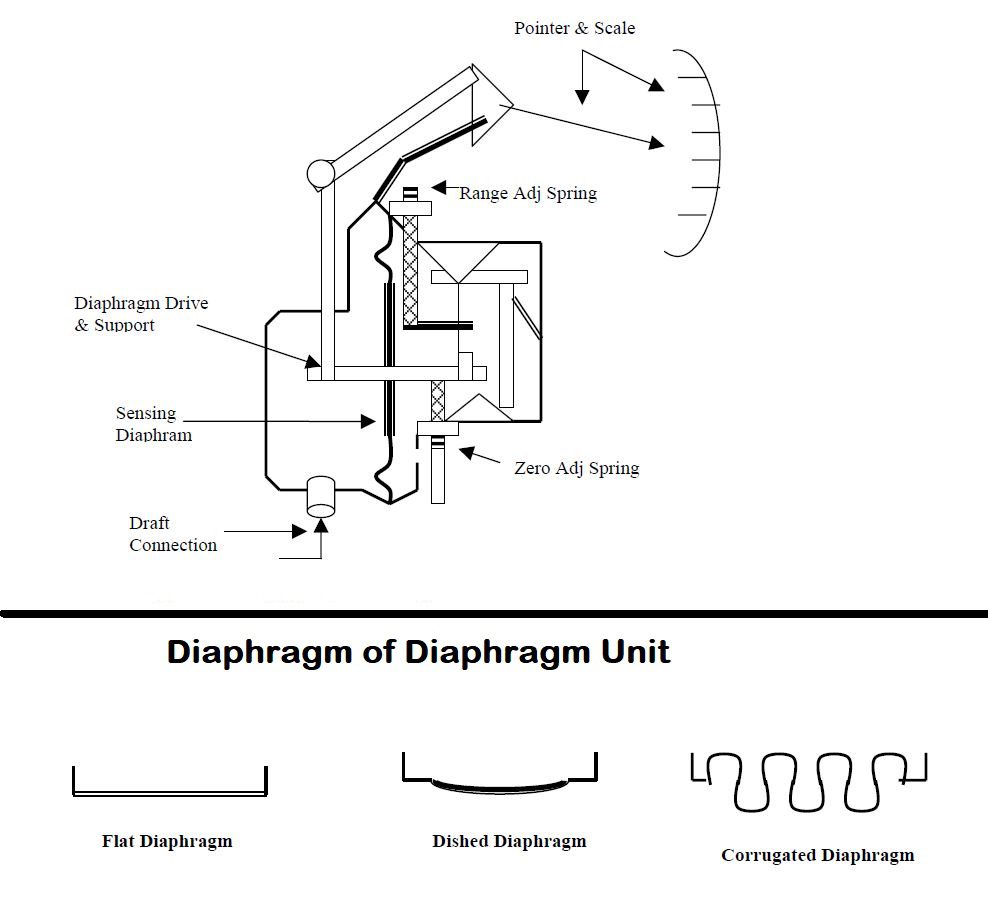

Diaphragm Elements

The introduction of diaphragm elements has greatly facilitated the pressure and draft measurements, particularly in very low ranges and when coupled with electrical circuits, these offer the transmission of reading to remote points. These will detect a pressure differential even in range of 0 to 4 mm. This consists essentially of a calibrated spring, sealed link and a diaphragm. Due to pressure differential, when the diaphragm moves to left, the calibrated spring opposes this movement. The motion is then transmitted to sealed link and hence to the pointer. The range and zero adjusting screw are used for calibration.

Working Pressure Rating of different Pressure sensing Elements

| Name of Pressure Element | Minimum Range(Psi) | Maximum Range(Psi) |

| Diaphragm | 0 to 2 | 0 to 400 |

| Bellows | 0 to 5 | 0 to 800 |

| Bourdon Tube | 0 to 12 | 0 to 100000 |

| Helix | 0 to 50 | 0 to 10000 |

| Spiral | 0 to 15 | 0 to 4000 |

| Capsule | 0 to 1 | 0 to 50 |

Read Also