Table of Contents

Introduction-

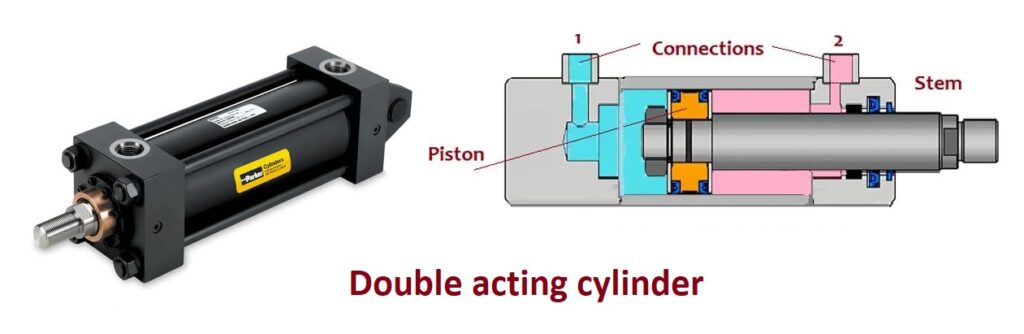

A double acting cylinder is such cylinder device that has usually two signal ports for the connection to apply pneumatic or fluid pressure to push or to pull a piston enclosed in cylinder. such cylinder works based on alternate cycles of pressurized air or fluid to both sides of the piston which creates extend and retract forces to move the piston rod i.e. permitting movement to push or pull. Thus there is no need of spring to revert in its original position. A typical double acting cylinder diagram is shown below-

इस टॉपिक को हिंदी में पढ़े  Double acting cylinder symbol

Double acting cylinder symbol

double act cylinders symbol of various configurations is shown below-

Application-

- Double acting pneumatic cylinder

- Double acting hydraulic cylinder

- Double acting actuator

- Double acting solenoid valve

- Double acting reciprocating pump

- Double acting compressor, etc.

Double acting pneumatic cylinder-

When a double act cylinder uses compressed air or gas supply for its operation or when cylinder is operated by pneumatic supply, it is called as double acting pneumatic cylinder. They are utilized to move a load in a linear or straight line path and their application is where machine requires more than one movement. Pneumatic systems utilize air pressures of (80 to 100) PSI for their operation. Compressed air applied at one port enables piston forward (push) and air into another port retracting the piston back (pull) into the cylinder. A diagram of double acting pneumatic cylinder is shown below-

Double acting hydraulic cylinder-

When a double act cylinder uses fluid pressure (mostly oil) for its operation or when cylinder is operated by hydraulic pressure, it is called as double acting hydraulic cylinder. Hydraulic cylinders are used for large force and heavy load application because typically hydraulic pressure can be up to 400 bar (6000 PSI). Double acting hydraulic cylinder working is similar as pneumatic cylinders. Here, compressed fluid entering though one port enables piston forward (push) and fluid entering into another port retracting the piston back (pull) into the cylinder. A diagram of double acting hydraulic cylinder is shown below-

Double acting actuator-

For application as double acting actuator, they utilize pneumatic or hydraulic supply to move piston rod in straight line which is connected to a control valve, guide vane or damper etc. For their operation, in double acting actuator, control pressure is applied at one inlet port of actuator to operate or open the valve, while control pressure applied ant another port enable valve to close.

Double acting solenoid valve-

Solenoid valve is electrically operated valve that uses electric supply for on-off application of control valves, emergency shutdown valves. Normally It consists of electric coil with a movable ferromagnetic core (plunger) in its center. In double acting solenoid valve, it is required 2 power supply to energize two separate coils. Coils are energized alternatively to move plunger at only one direction at a time. When electric voltage is applied to the coil 1, a magnetic field is created, and it forces the plunger to move upward and enables opening one set of orifice to pass fluid and another set of orifice to block fluid. When electric voltage is applied to the coil 2, generated magnetic field forces the plunger to move downward and enables closing of one set of orifice to block fluid and another set of orifice to pass fluid. Thus there is no spring required. A double acting solenoid valve is shown below-

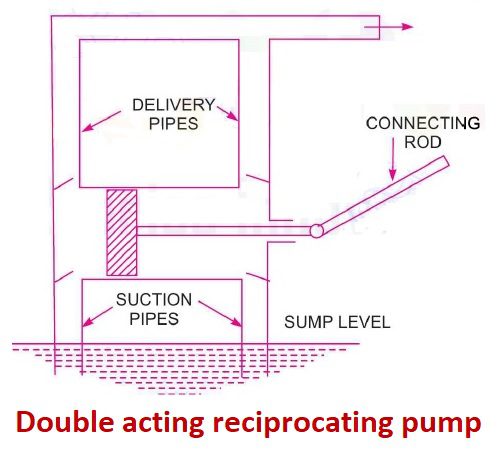

Double acting reciprocating pump-

In case of double acting reciprocating pump, working fluid or water will be acting on both the side of the piston. Therefore, they will have two suction piping and two delivery piping. A double acting reciprocating pump as shown in following figure-

When there will be a suction stroke on one side of the piston, at the same time there will be a delivery stroke at another side of the piston. Hence, in this case, there will be two suction strokes and two delivery strokes for one complete revolution of crank and water will be discharged through the delivery pipes during these two delivery strokes.

Double acting compressor-

A double-acting compressor is also named as positive displacement compressor and belongs to reciprocating compressor category. Here in double-acting reciprocating compressor it utilizes both sides of the piston for air or gas suction and compression. The inlet and outlet valves opening and closing is according to the stroke or piston movement. Double acting compressor working is a slightly different from single-acting compressor. In single-acting compressor, only one side of the piston works. A diagram showing working of double acting compressor is shown below-

Click on the below links to read more about-

- Single acting cylinder

- Difference between single acting and double acting cylinder

- What is an actuator?

- Pneumatic Actuator

- Hydraulic Actuator

- What is control valve?

- Electric actuator

- What are different types of actuator?

- Sensor Vs Actuator

- Sensor Vs Transducer

- Piston (Wikipedia link)