Table of Contents

Definition-

A Single acting cylinder is such cylinder device that has usually only one signal port for the connection to apply pneumatic or fluid pressure to push a piston enclosed in cylinder. It is also known as a plunger cylinder having one piston within a cylindrical housing. It works normally based on spring return mechanism to retain its original position when no external pressure present. Such cylinders deliver linear or straight line motion. It is used for pulling, pushing, lifting, moving and holding the load applications. A diagram for single acting cylinder is shown below-

Available configuration–

There are various configurations available, as shown in figure-

Single acting cylinder symbol

Symbol for various configurations is shown below-

Application–

- Single acting pneumatic cylinder

- Single acting hydraulic cylinder

- Single acting actuator

- Single acting solenoid valve

- Single acting reciprocating pump

- Single acting reciprocating compressor

- Single acting reciprocating engine, etc.

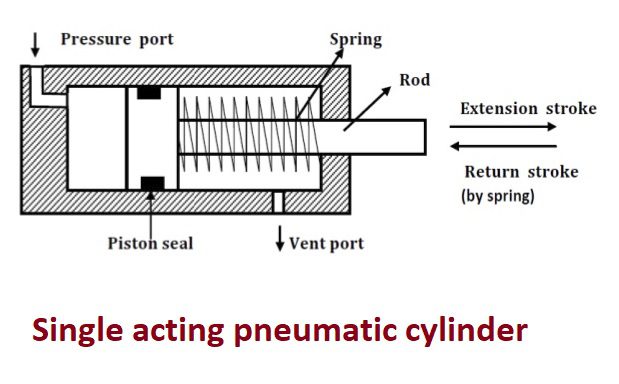

Single acting pneumatic cylinder-

When such type of cylinder uses compressed air or gas supply for its operation or cylinder is operated by pneumatic supply, it is called as single acting pneumatic cylinder. Mostly such actuator is spring return mechanism to retain its normal state. Pneumatic systems utilize air pressures of (80 to 100) PSI for their operation. A diagram of single acting pneumatic cylinder is shown below-

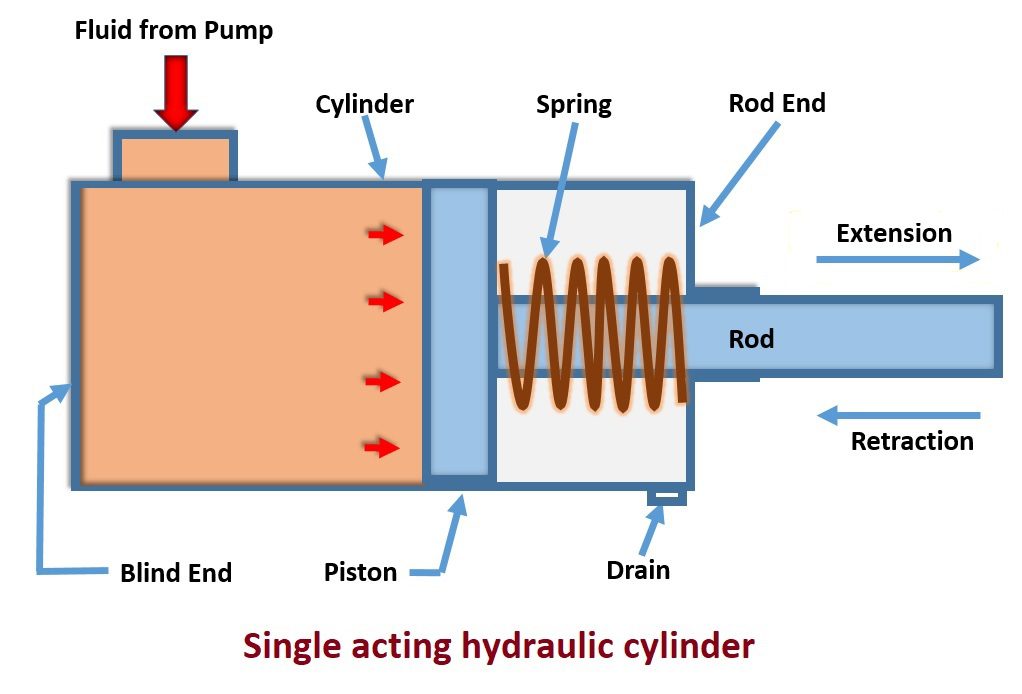

Single acting hydraulic cylinder-

When a such type of cylinder uses fluid pressure (mostly oil) for its operation or cylinder is operated by hydraulic pressure, it is called as single acting hydraulic cylinder. Hydraulic cylinders are used for large force and heavy load application. Here hydraulic pressure can be up to 400 bar (6000PSI). A diagram of single acting hydraulic cylinder is shown below-

Single acting actuator-

For application as single acting actuator, they utilize pneumatic or hydraulic supply for their operation. In single acting actuator, control pressure is applied at one inlet port of actuator to operate/ open the control valves, and valve closing is determined by stored energy of spring. A diagram of single acting actuator is shown below-

Single acting solenoid valve-

Single acting solenoid valve is electrically operated valve that uses electric supply for on-off application of control valves, emergency shutdown valves. Solenoid valve consists of an electric coil with a movable ferromagnetic core (plunger) in its centre. When electric voltage is applied to the coil, current passes through the coil which creates a magnetic field. The magnetic field forces the plunger to move upward and enables opening the orifice or closing of orifice depending on its valve configuration. Solenoid valves can be 2 port, 3/2 port, 4/2 port or 5/2 port structure as per their requirement using a single piston. They utilize spring return arrangement to get its original position. A single acting solenoid valve is shown below-

Single acting reciprocating pump-

Reciprocating pump is a device that converts the mechanical energy into hydraulic energy by sucking the liquid into a piston cylinder. In this pump, a piston is reciprocating, which uses thrust on the liquid and increases its hydraulic pressure or energy. Reciprocating pump is also known as positive displacement pump because it discharges a definite quantity of liquid. It is normally used for smaller volume or smaller liquid quantity to handle but delivery pressure is quite large. A working diagram for reciprocating pump is shown below-

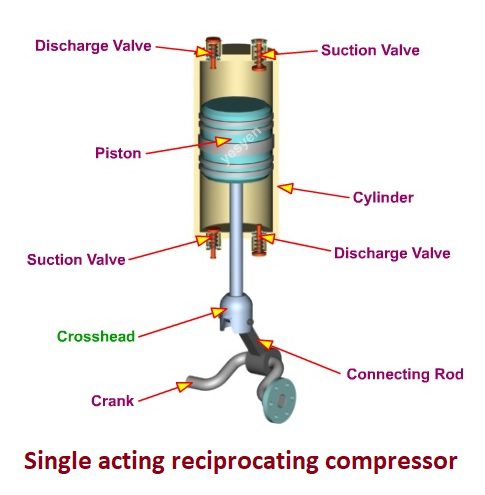

Single acting reciprocating compressor-

A compressor is used to transfer the compressible fluids from one place to other after compressing. Single acting compressor is a positive displacement compressor from the category of reciprocating air compressors. A single-acting reciprocating compressor is a type of air compressor which uses only one end of the piston for the suction and compression purpose. It uses compressed air to push piston in one direction and spring force to send piston back to its primary position. Thus it uses only one piston for supplying and discharging pressurized gas or air. A working diagram for reciprocating compressor is shown below-

Single acting reciprocating engine-

A single-acting cylinder in a reciprocating engine is a common application of such type of cylinder in which the working fluid acts only on one side of the piston. Single-acting cylinders rely on the load, springs, other cylinders, or the momentum of a flywheel, to push the piston back in the other direction. Single-acting cylinders are found in most of the reciprocating engine. Such reciprocating engines are almost universal in internal combustion engines (i.e. petrol engine and diesel engine) and are also used in many other external combustion engines such as Stirling engines and some steam engines too.

Difference between single acting and double acting cylinder-

| Sr. No. | Single acting cylinder | Double acting cylinder |

| 1 | A Single acting cylinder has only one signal port for the connection to apply pneumatic or fluid pressure to push a piston enclosed in cylinder. | A double acting cylinder has two signal ports for the connection to apply pneumatic or fluid pressure to push or to pull a piston enclosed in cylinder. |

| 2 | Its retraction method is based on spring return mechanism (to retain its original position) | For retraction, hydraulic or pneumatic supply at another port is required to apply. |

| 3 | It offer control for unidirectional movement since pressurized fluid is applied at one end to move piston either to push or to pull. | It has more control over movement since pressurized fluid is applied at both ends to move piston both the side. |

| 4 | Retraction control depends on spring so less control on retraction. | It offers good retraction control. |

| 5 | Cost is low comparatively. | Cost is higher comparatively. |

| 6 | Due to spring mechanism, its response time is little slower that double acting type. | They are very fast to operate as no spring is present here. |

| 7 | Some advantages are-

|

Some advantages are-

|

| 8 | Some disadvantages are-

|

Some disadvantages are-

|

Click on the below links to read more about-

- Double acting cylinder

- What is an actuator?

- Pneumatic Actuator

- Hydraulic Actuator

- What is control valve?

- Electric actuator

- What are different types of actuator?

- Sensor Vs Actuator

- Sensor Vs Transducer

- Piston (Wikipedia link)