Table of Contents

Strain Gauge is a variable resistive transducer which is used to measure strain or change in length or distance produced by external force (i.e. expansion and or compression) or pressure. Strain gauge uses electrical property of material (mostly either conductor or semiconductor) that whenever there will be deformation in dimension of the material, its electrical resistance changes. It consists of a long thin piece of metal which is arranged like zig-zag across the sensor or folds back on itself. A simple diagram for strain gauge is shown in figure-

Working principle

Since we know that electrical resistance (R) of a conductor is proportional to the length (l ) of the conductor and inversely proportional to the cross section area (A) of the conductor i.e.-

From the formula, it is understood if a process variable such as force, pressure or displacement etc. makes change in length or area (both or any of them) of sensor, will change in resistance of the same. For the measurement of such variables, strain gauge is mounted upon the object to transfer the effect of the force or displacement. When an external force is applied to the object, there is a deformation occurs in the shape of the object which is transferred to the strain gauge sensor and thus a change in resistance occurs which can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable such as force, pressure, weight, stress, length or displacement etc.

To measure change in resistance using wheat stone bridge circuit is shown as follows-

Since we know that initially when there is no strain applied to strain gauge, bridge circuit is set to balance condition and the ammeter across both the potential divider network shows zero current. As stress is applied to the strain gauge, electrical resistance of the gauge varies which causes imbalance of the bridge and results into current in ammeter. There are two methods for detection of change in resistance-

- Null Mode

- Deflection mode

In null mode, we produce similar change in RC to achieve null balance condition across bridge network. While in deflection mode, unbalance current is directly measured and calibrated in form of change in resistance or in terms of change in physical quantity such as force, pressure, displacements, weight etc. to be measured.

Possible configuration of strain gauges in bridge circuit-

- Quarter Bridge using single gauge

- Half Bridge using two gauge

- Full Bridge type

In Quarter bridge arrangement, a single strain gauge is used in one arm of wheat stone bridge and in other arms fixed resistors are used.

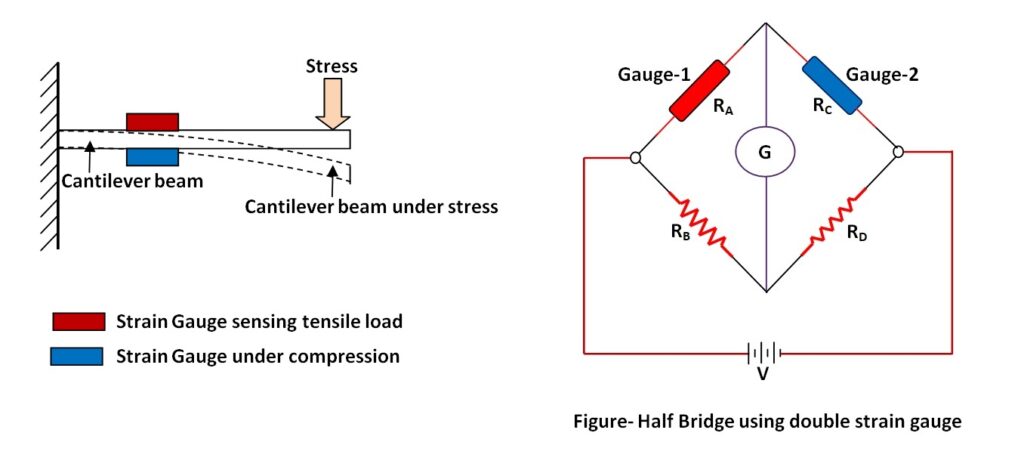

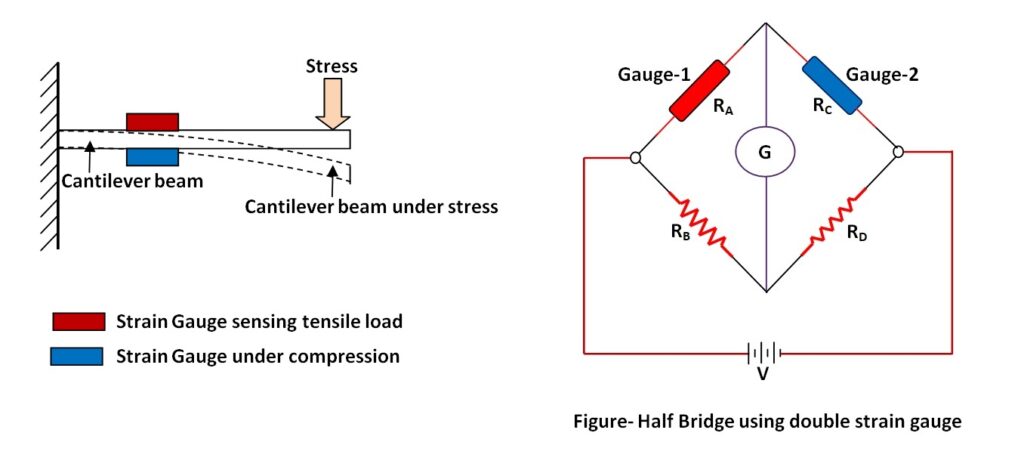

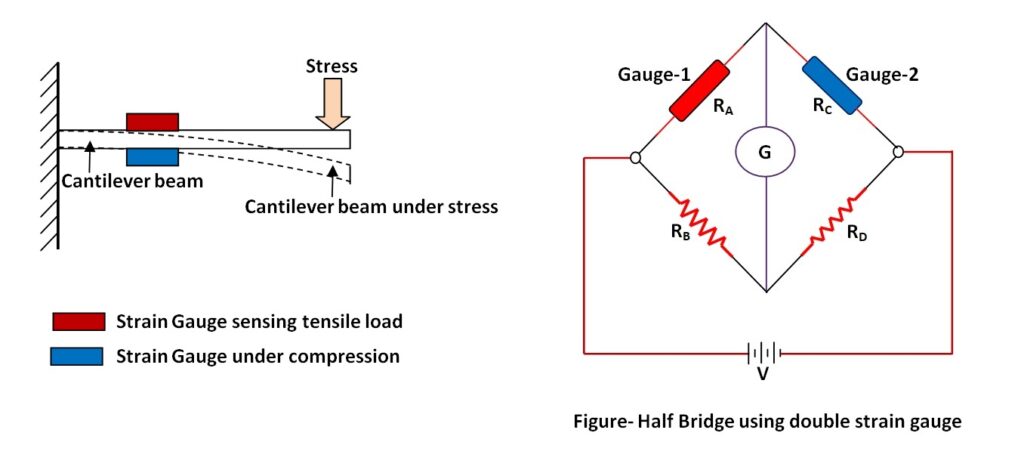

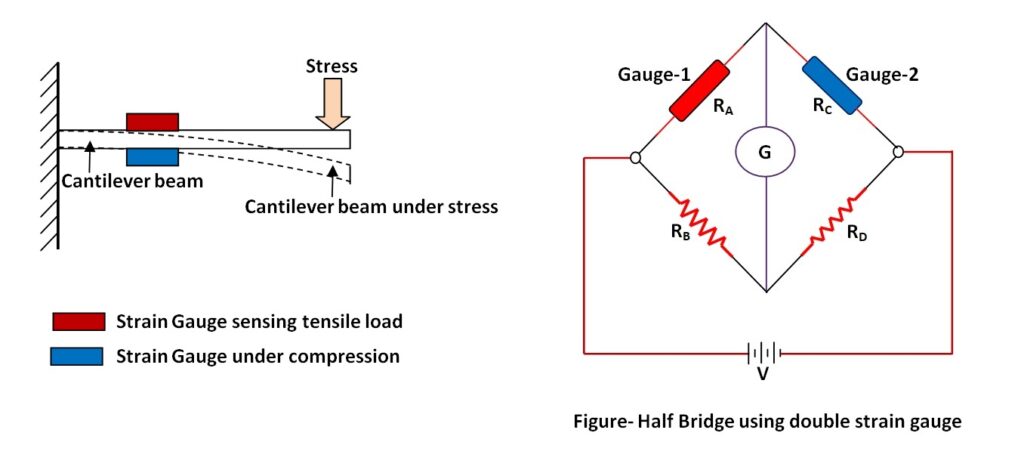

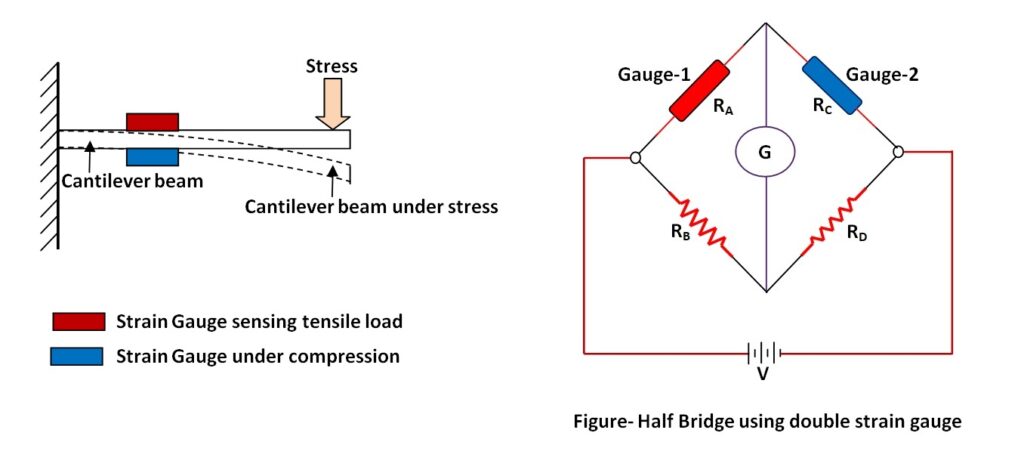

In order to increase the resistance change output and compensate temperature effect, double gauges are used (as shown in figure) in which one gauge senses tensile force and its resistance increases due to tensile load while another gauge faces compression force and its resistance decreases due to compressive strain. Other two arms of bridge are fixed resistors.

In order to increase sensitivity and output in change in resistance, four gauges are used in each arm of wheat stone bridge as mentioned in figure-

Types of strain gauge

There are various types of strain gauge sensors widely used in industries. A broad classification is shown as follows-

- Wire wounded type strain gauges

- Bonded type gauge

- Unbonded type gauge

- Foil type gauge

- Semiconductor gauges

- Capacitive strain gauges

Note- Click on individual tab to read more…

Application of strain gauge

Resistance Strain Gauges are very small in size and much sensitive electrical transducers. They are often used in other sensors to measure different physical variable and convert into electrical form and produces change in resistance hence change in current / voltage. Some of them are mentioned below-

- Stress and strain (Micro-strain) measurement

- Weight measurement (In Load cell)

- Displacement Measurement

- Pressure measurement

- Force measurement

- Torque measurement

- Temperature measurement (Sometimes), etc..

Requirements of Ideal Strain Gauge-

- They should have high gauge factor

- They should have high resistivity

- They should have low temperature sensitivity

- They should have high yield point

- Their corrosion resistant should be high.

Related Search:-

Stain Gauge Rosette