Table of Contents

Introduction-

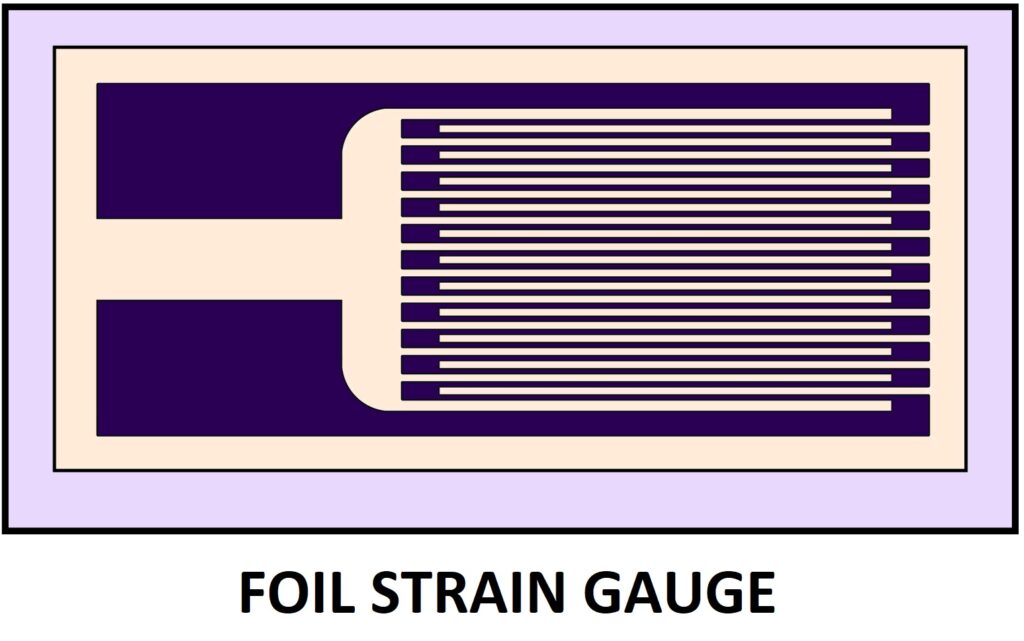

Foil strain gauge is an extension of resistance wire strain gauge. Here this gauge also uses a resistance material foil deposited over an insulating material such as Bakelite rather than winding a wire. The metals and alloys used for foil are similar to wire material used in wire wounded strain gauge.

Why to use foil type gauge?

Foil type gauges are having more advantages over wire strain gauge as given below-

- They are having a much higher dissipation capacity than wire wound gauges due to their larger surface area for the same volume. So they can be used for higher operating temperature ranges.

- In addition, the larger surface is of foil gauge leading to better bonding.

- No stress concentration exists on terminals.

- These gauge transducer can be fabricated on a large scale and in any shape.

- These gauge transducer have similar properties to wire strain gauges. Their gauge factors are usually the same.

- These gauge are manufactured using diffusion process. So as a resistance foil, semiconductor materials can be used. Thus we can achieve high gauge factor / strain sensitivity to detect a very small change in length.

Construction-

The foil is achieved by etching and deposition technique on a carrier. Etched foil gauge manufacturing involves first attaching a layer of stress sensitive material to a thin sheet of paper or bakelite. The metal part used as the wire element is covered with a suitable masking material, and an etching solution is applied to the unit. The solution removes the part of the metal that is not masked, leaving the desired grid structure intact.

A diagram of foil type strain gauge is shown as follows-

Strain Gauge foil material-

There are various resistance materials available to construct strain gauge. Gauge wires are made up of metals, or alloys. Some of them are as follows-

- Constantan (Copper nickel alloy)

- Nichrome (Nickel Chromium alloy)

- Isoelastic (Fe + Ni + Cr)

- Platinum alloy, etc.

Semiconductor materials used for foil strain gauge-

- P type Silicon

- N type Silicon

- P type Germanium

- N type Germanium

- Single crystal silicon

- Poly-silicon

Working –

When Foil strain gauge is attached to the structure surface under study and structure is subjected to a force, gauge gets elongated, hence a change in resistance occurs which can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable such as force, pressure, stress etc.

To read more about other strain gauge types click on individual links here-

- Types of Strain gauge

- Bonded strain gauge

- Unbonded strain gauge

- Semiconductor strain gauge

- Strain Gauge Rosettes

- Gauge Factor

- Stress – Strain Curve