Table of Contents

Resistive transducer is also called as Variable resistance transducer. Resistive transducers are those devices in which resistance varies due to effect of physical quantity to be measured. When a physical quantity such as temperature, pressure, displacement, vibration, force etc. make changes in resistance or resistivity of the sensor material, these sensors are termed as resistive sensors. Resistive transducer acts like primary transducer and as well as secondary transducer. The change in resistance can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable.

Working principle of Resistive transducer

Since we know that resistance (R) of a conductor is proportional to the length (l ) of the conductor and inversely proportional to the cross section area (A) of the conductor i.e.-

From the formula, it is understood that the variable resistance transducer elements work on the principle that the resistance of the conductor is directly proportional to the length of the conductor and inversely proportional to the area of the conductor. So if a process variable make change in length or area (both or any of them) of sensor or transducer, will change in resistance of the same, which can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable.

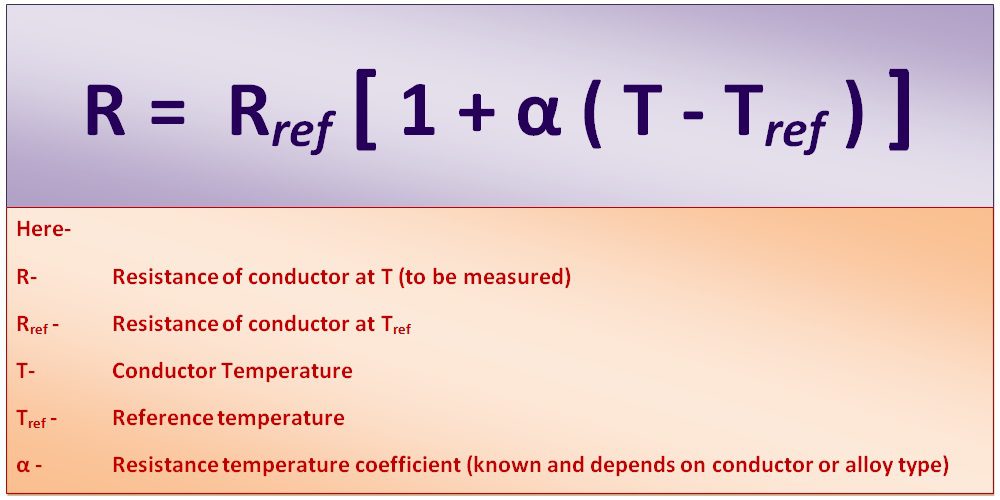

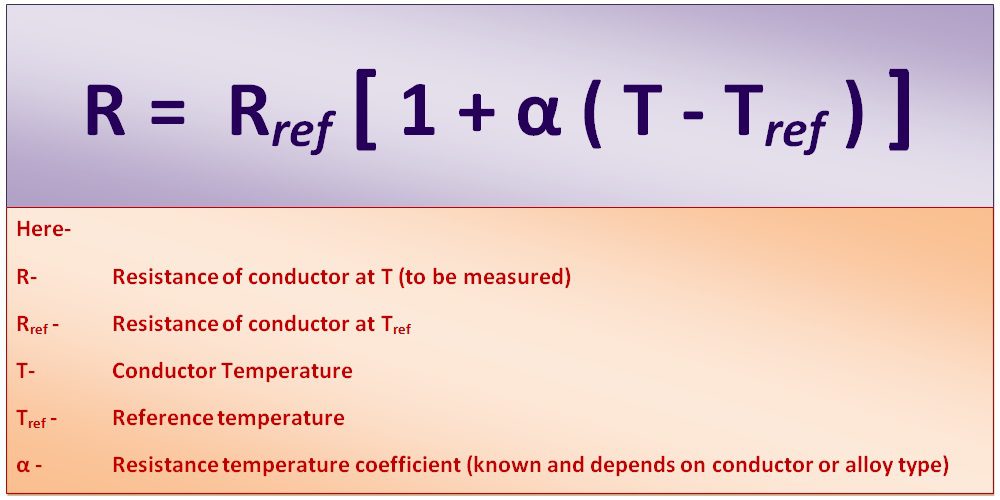

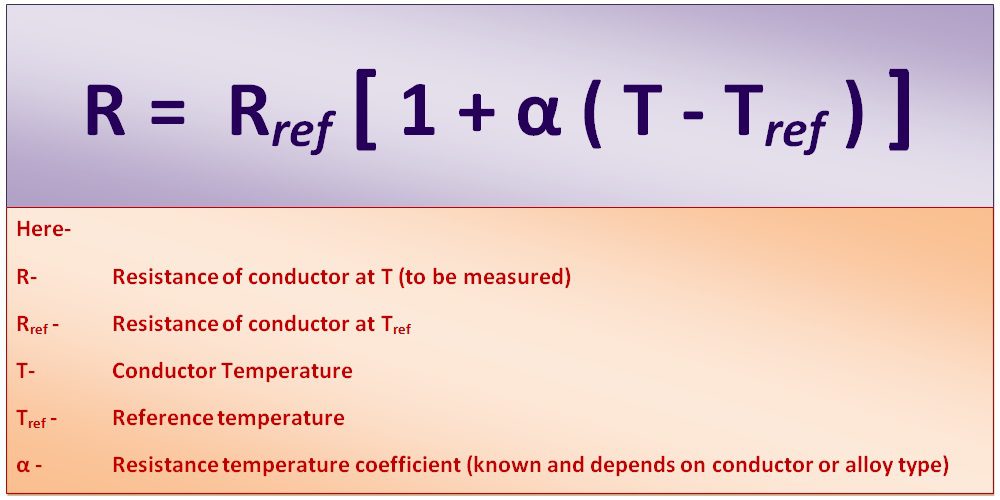

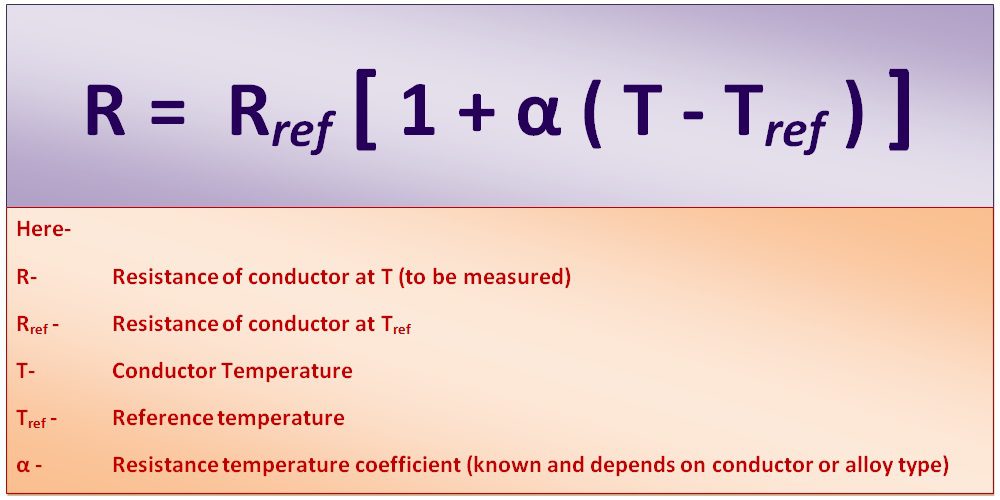

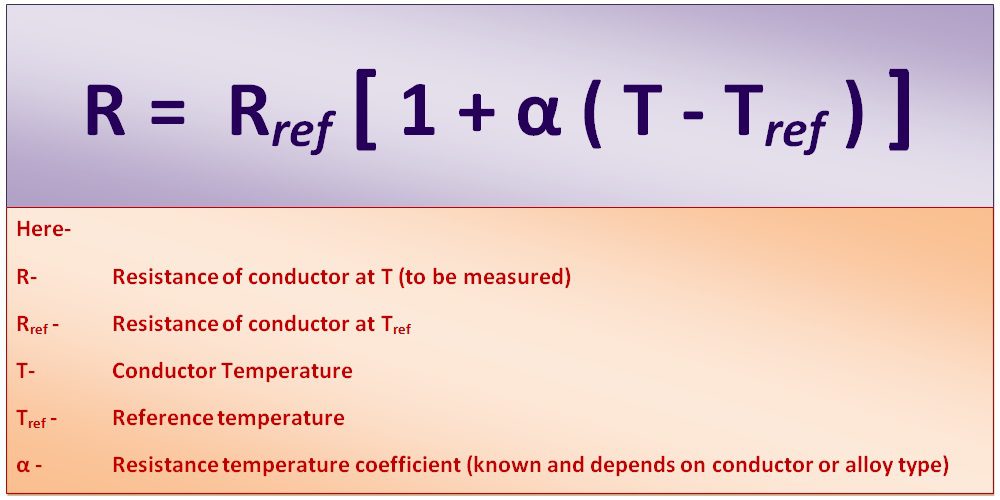

Another principle for the change in resistance of sensor or transducer is change due to temperature. Since we know that for the conductors and alloys, a change in resistance is a function of change in temperature and the resistance-change factor per degree Celsius of temperature change is called the “Temperature coefficient of resistance”. This factor is represented by the “alpha” (α). An equation for R-T relation is shown below-

Here in the formula, value of Resistance Temperature Coefficient (α) depends on the conductor or alloy material it can be either positive or negative. A positive coefficient represents resistance increases with an increase in temperature while a negative coefficient represents resistance decreases with increase in temperature.

As conclusion, if a process variable makes change in length or area (both or any of them) and/ or change in temperature of sensor or transducer, will change in resistance of the same, which can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable.

Resistive Transducers types-

There are various type of resistive transducer used for industrial application. Some examples of resistive transducers are shown below- (Click individual tab to read more)

|

Potentiometer |

– converts displacement into change in resistance |

|

Resistance thermometer (RTD) |

– detects change in temperature and convert into change in resistance |

|

Thermistor |

– detects change in temperature and convert into change in resistance |

|

Strain Gauge |

– convert force, pressure into change in resistance |

|

Hot wire meter |

– used to detect liquid or gas velocity by measuring the heat loss of wire placed in the fluid stream by detecting change in resistance. |

|

Light dependant resistor (LDR) |

– detect light intensity and results as change in resistance |

|

Resistance Hygrometer |

– detect humidity present in its surrounding atmosphere and convert in form of change in resistance |

Read Also:-

Related Search:-

I to H Converter

I to H Converter

Valve Position Transmitter

Valve Position Transmitter

What is pressure switch?

What is pressure switch?

Electrical Transducer

Electrical Transducer

pH Measurement

pH Measurement