Table of Contents

FLOW SWITCHES | What is a Flow Switch?

Flow switches are devices that monitor the flow through a channel and send a trip signal to various devices such as Pump.The pump can be indicated by the flow switch to shut down or turn on. Some of the general uses are for the protection of the pump, protection of the cooling circuit and alarms for flow rates that are too high or too low.A flow switch is used to monitor the flow of liquids, air or other gaseous media through a duct, system or loop.These switches or sensors can be used to monitor flow over a given period of time, or set up to continuously monitor total flow.

What Does Flow Switch work?

To understand how a flow switch works and what it does, it’s helpful to outline the core components that make up a typical switch. Many types will include a paddle or magnetic trigger of some sort (the primary device), which is connected to a circuit and placed in the channel through which liquid or gas is passing. This paddle is displaced or rotated by whatever substance is flowing by, and sends a signal to a secondary component known as the transducer.

The transducer takes this raw signal from the paddle and passes it on to a transmitter in a readable format. The transmitter, in turn, measures this reading against a predefined set of parameters and performs whatever signal or action is required to adjust the behaviour of components and mechanisms elsewhere.

In this way, flow switches are able to monitor report and control the flow rate of liquid or gas through a specific part of a system, or through the entire system, ensuring flow stays within those pre-set parameters. If the rate exceeds or drops below what’s required, it can instantly trigger a series of actions such as activating an alarm, powering on a pump, diverting flow, shutting off parts of the system. Which actions a switch performs will depend entirely on the type of switch and what it’s been designed for.

Not all flow switches will have a physical paddle as such. Ultrasonic and other non-intrusive versions are also fairly commonplace, which work by bouncing a signal back off the medium being monitored. This is particularly useful in cases where the medium is contaminated, physically damaging or otherwise hazardous, or where it’s helpful to have no moving parts exposed to constant wear and tear.

Types of Flow Switch:-

There are numerous different types of flow switches available.

Paddle or Flapper Type Flow Switch:-

The flow switch consists of a paddle/flapper device hanging with the flat surface facing the direction of flow through a hinge. A permanent magnet is connected to this end; a reed contact above this magnet is located outside the fluid flow.

Diaphragm Type Flow Switch?

In construction, diaphragm type flow switches are similar to Differential Pressure switches. The only difference is that there is a gap that allows fluid to flow through the transition between the inlet and the outlet port, while it is completely closed in Differential Pressure switches.

Installing these switches allows the inlet port to be on the same line as the outlet port. The liquid flow usually takes a zigzag route inside the switch body when this is completed. This effect results in a significant drop in pressure, which happens when a liquid flows through the flow switch.

The spindle begins to rise or fall depending on the extent of the flow due to the movement of DP across the self-created orifice of the switch housing and the compression spring connected to the diaphragm assembly via a spindle.

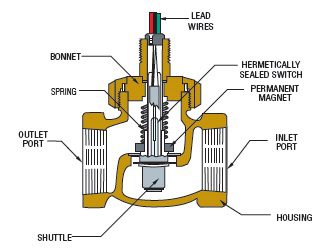

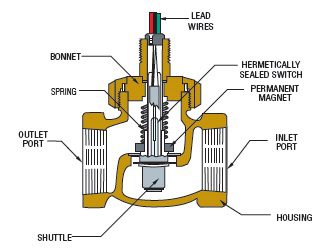

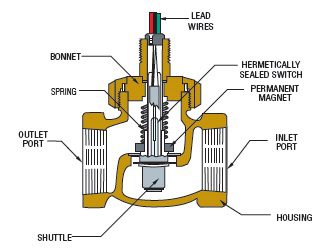

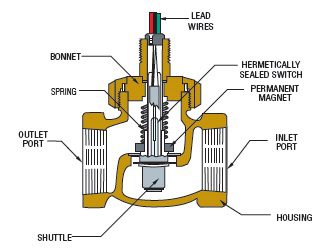

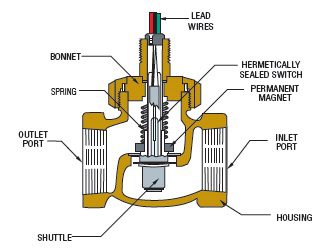

Shuttle Type Flow Switch:-

Shuttle style flow switches operate because of DP or the velocity of the liquid acting on a disk on the concept of a moving force. As liquid flow increases to the actuation setting, a magnet-equipped shuttle is displaced.

When displaced by fluid flow, this shuttle actuates a hermetically sealed, SPDT or SPST reed switch within the unit stem. A compression spring or gravity provides shuttle return when flow decreases.

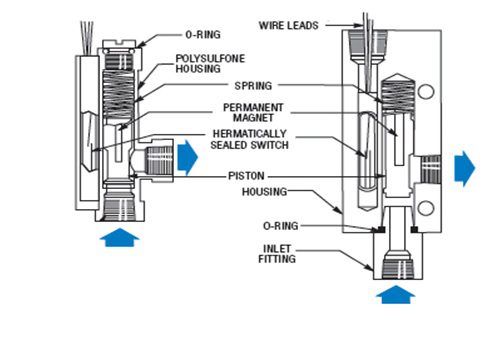

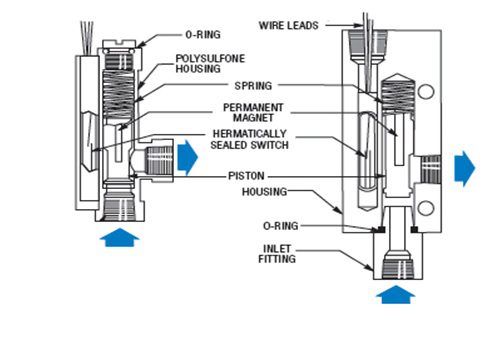

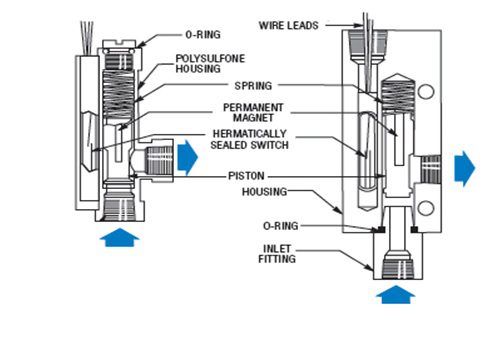

Piston Type Flow Switch:-

A piston flow switch, encapsulating a permanent magnet, is positioned in the flow path within the unit housing. When displaced by the pressure differential from fluid flow, this piston magnetically actuates a hermetically sealed reed switch (SPST or SPDT, depending on the series) within the unit.

The piston metering land diameter precisely sets the actuation point by regulating bypass clearance. A stainless steel spring provides positive piston return as flow decreases. The reed switch, when actuated, can be used to operate remote alarms or indicators. Or, it may be integrated into automatic system controls.

Thermal Flow Switch:-

There are many applications where knowing whether there is flow or a no-flow condition of a fluid in a pipe is important. A thermal flow switch is an option to consider providing such positive indication of flow or no-flow conditions. a thermal flow switch operates without any moving parts and therefore is more reliable.

A thermal flow switch, also known as a thermal dispersion flow switch, is a precise flow sensing device. The principle sensing method is that of heat diffusion. “The operation of thermal dispersion flow sensing is attributed to L.V. King who, in 1914, published his famous King’s Law revealing how a heated wire immersed in a fluid flow measures the mass velocity at a point in the flow. King called his instrument a “hot-wire anemometer”. However, it was not until the 1960s and 1970s that industrial-grade thermal dispersion devices finally emerged.”

A typical thermal flow switch consists of two temperature sensors. One sensor measures the temperature of the fluid when the sensor probe is immersed in the liquid. The other temperature sensor is heated by a constant power. This creates a temperature difference between the two sensors. According flow switch gives an output.

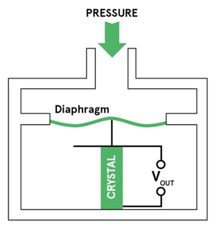

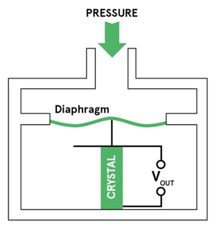

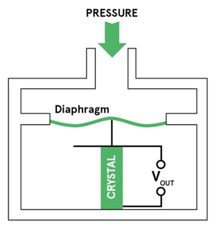

Piezoelectric Flow Switch:-

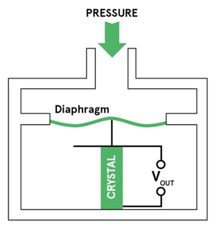

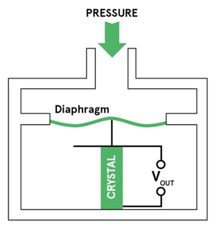

Piezoelectricity is the charge created across certain materials when a mechanical stress is applied.

Piezoelectric flow switch exploit this effect by measuring the voltage across a piezoelectric element generated by the applied force or pressure. They are very robust and are used in a wide range of industrial applications.

When a force is applied to a piezoelectric material, an electric charge is generated across the faces of the crystal. This can be measured as a voltage proportional to the pressure.

A given static force results in a corresponding charge across the sensor, by using electronic circuit we can generate a digital output at set flow.

Read Also:-

Instrumentation Cable | Types and Application

Related Search:-

Pressure regulator

Pressure regulator

Tuning fork Type Level Switch

Tuning fork Type Level Switch

DP transmitter calibration

DP transmitter calibration

Electromechanical Pressure Switch

Electromechanical Pressure Switch

Capacitive level switch

Capacitive level switch

Level Switches working

Level Switches working