Table of Contents

xnx gas detector calibration

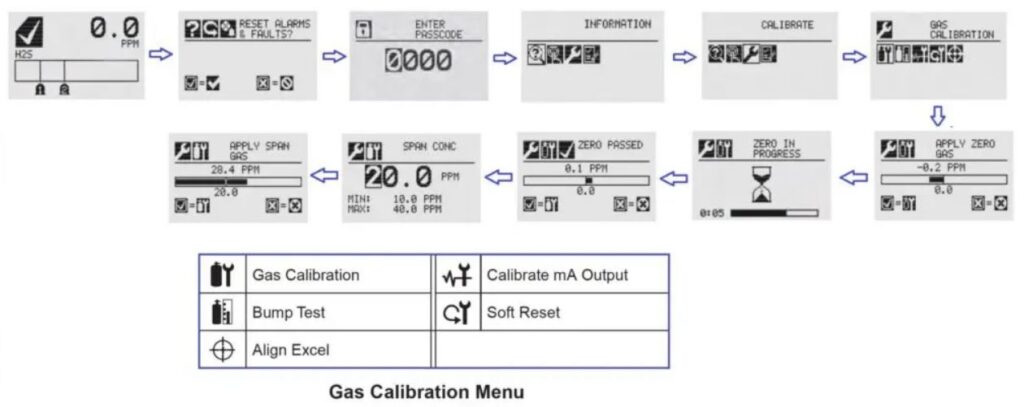

The process of xnx gas detector calibration is- Depending on the user’s security level, access is controlled at two levels. The factory-set passcodes for both levels are “0000.” Allow the detector to settle for 30 minutes after adding power before doing the initial calibration. In order to prevent false alarms, the current output from the detector is blocked (by default 3mA) when in zero and span calibration mode. Due to PTFE’s rigidity, it is advised that the tubing for the majority of sticky gases (such as HCl and chlorine) be made of PTFE and small portions of rubber tube for the final connection. Apply zero calibration gas now, then execute zero calibration once the reading has stabilised. Apply span calibration gas, then execute span calibration once the reading has stabilised. To understand the XNX GAS DETECTOR CALIBRATION in better way a screen shot of sequence of steps in screen is given below.

Read Also

xnx gas detector calibration 9 | xnx honeywell gas detector calibration xnx

step by step xnx gas detector calibration is below.

- Open the Menu for programming.

- Select the Calibration menu after entering the menus by pressing the (✓) key.

- Select the Gas Calibration option(Menu) and press the (✓) key.

- Apply zero gas; once the reading for zero gas is stable, press (✓) to confirm the calibration of zero.

- The Zero Passed screen will appear on the transmitter if the zero calibration is successful.

- To execute Span Calibration, press (✓), to skip it and return to the Calibration menu, select (✖).

- By using the (+) or (-) options to increase or decrease the values, enter the span gas concentration. To accept the value and continue on to the following digit, use (✓). Continue until all digits have been selected.

- When the span reading is stable, apply span calibration gas; then, tap (✓) to ensure span calibration.

- The transmitter will show the Span Passed screen if the span calibration is successful.

- After finishing, the user will be given the option to “Exit with Inhibit Off,” “Exit with Inhibit On,” or “Do not exit.”

So this was, how to perform gas detector calibration, hope it will help you to perform the calibration on gas detector.

XNX gas detector sensor’s calibartion life

The use, frequency, and volume of gas exposure all affect the typical life of a poisonous gas sensor. The hazardous sensor is intended to have a lifetime that is equivalent to or greater than those mentioned below under typical circumstances (3 month visual examination and 6 month test/recalibration).

18 months for sensors for chlorine and chlorine dioxide.

For Ammonia and Hydrogen Fluoride sensors, one year.

Oxygen and other hazardous sensors have a 24-month lifespan.

Read Also

- Sample System in Analyzer | Sampling

- CO trace Analyzer Calibration-Siemens Ultramat-6

- Sulphur Analyzer

- Feedforward Control | Feedforward | Feedforward control system