Table of Contents

There are basically three type of methods for measuring of Specific Gravity Analyzer.

- Gas Density Detector

- Gas Impulse Wheel Method

- Metering Orifice Method

Gas density detector

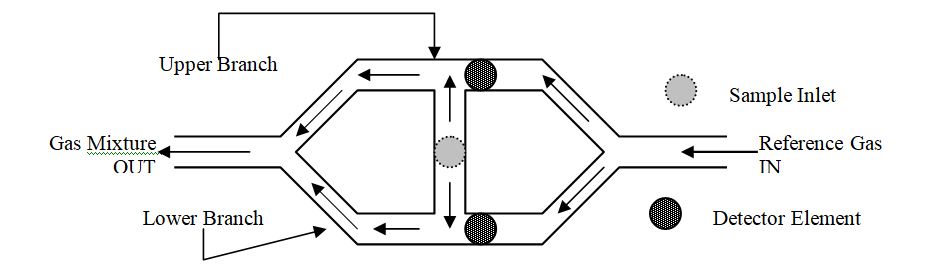

A continuous type measuring instrument, where a continuous flow of known reference gas as well as sample gas is coming in contact with two thermistors or hot wires, which are located vertically on the upper and lower branch/arms, one at the end Wheatstone bridge is connected, is balanced in exactly the same density. If the density of the sample gas is even slightly greater than the density of the reference gas, then a

The tendency of the sample gas to sink in the lower branch of a vertically placed liquid bridge. This disrupts the flow path, causing the temperature of the lower detector element to rise and the Wheatstone bridge to unbalance. So in the case of a lighter sample gas, the upper detector element causes a rise in temperature due to the flow restriction of the upper arm of the vertically positioned fluid bridge and unbalances the Wheatstone bridge.

Gas Impulse Wheel Method

In this method a continuous stream of gas sample is driven into the lower measurement chamber of the instrument by a gas impulse wheel and put into vortex motion and driven against the blades of a companion impulse wheel located in the same chamber. . The two wheels exert a torque on the other, each trying to turn in the opposite direction. The result is a net speed that depends on the difference in torque between the two impulse wheels and the position of the pointer needle. As the difference between the opposing torques is a function of the specific gravity of the gas, this is indicated by the indicator needle.

The impulse wheel is produced in the air chamber to compensate for changes in fan speed, temperature, humidity and atmospheric pressure. To achieve this, the gas sample and the air are brought to the same temperature and humidity by passing them through different compartments in the same humidifier. Due to the high sampling rate and small internal volume of the measuring chamber, the response to changes in gas density is almost instantaneous.

Metering hole method

In this method a constant sample is drawn from the process by a constant volume blower, through a pressure reducing valve that is set to a constant volume blower, through a pressure reducing valve that is set against the water column. Sets for a constant downstream pressure of about 10 cm. , In this way variations in the gas supply pressure are smoothed out, which in other cases would affect the gas sampling accuracy. The sample is then passed through the metering orifice and then through another orifice to the atmosphere. The line between the two orifice plates is tapped by a recycling line that connects back to the suction side of the blower. Atmospheric discharge is thus limited to about 30% of the blower capacity. The differential pressure of the constant volume flow across the metering orifices varies with the change in the specific gravity of the sample.

Read Also

- Sample System in Analyzer | Sampling

- CO trace Analyzer Calibration-Siemens Ultramat-6

- Sulphur Analyzer

- Feedforward Control | Feedforward | Feedforward control system