Table of Contents

Laminar flow meter is a flowmeter with a linear relationship between the volumetric air flow rate and its differential pressure. The differential pressure is low enough at the rated flow rate, so it does not affect the characteristics of any test parts.

Laminar flow is a state of fluid motion where viscous (internal fluid friction) greatly outweighs the inertial (kinetic) forces. In laminar flow conditions a fluid flow exhibits no turbulence, with each fluid molecule traveling in its own path, with limited mixing and collision with adjacent molecules.

The major mechanism for resistance to fluid motion in the laminar flow regime is friction with the walls of the pipe or tube. Laminar flow is qualitatively approximated by low values of Reynolds number.

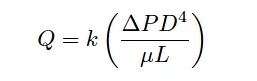

This pressure drop created by fluid friction in laminar flow is quantitative, and is expressed in the Hagen–Poiseuille equation:

Where,

Q = Flow rate

ΔP = Pressure dropped across a length of pipe

D = Pipe diameter

μ = Fluid viscosity

L = Pipe length

k = Coefficient accounting for units of measurement

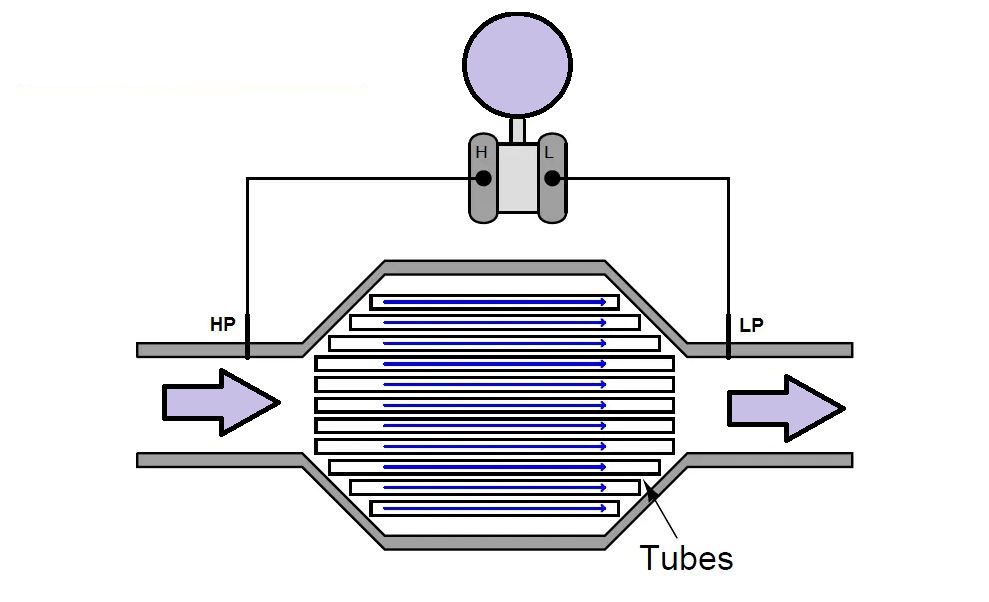

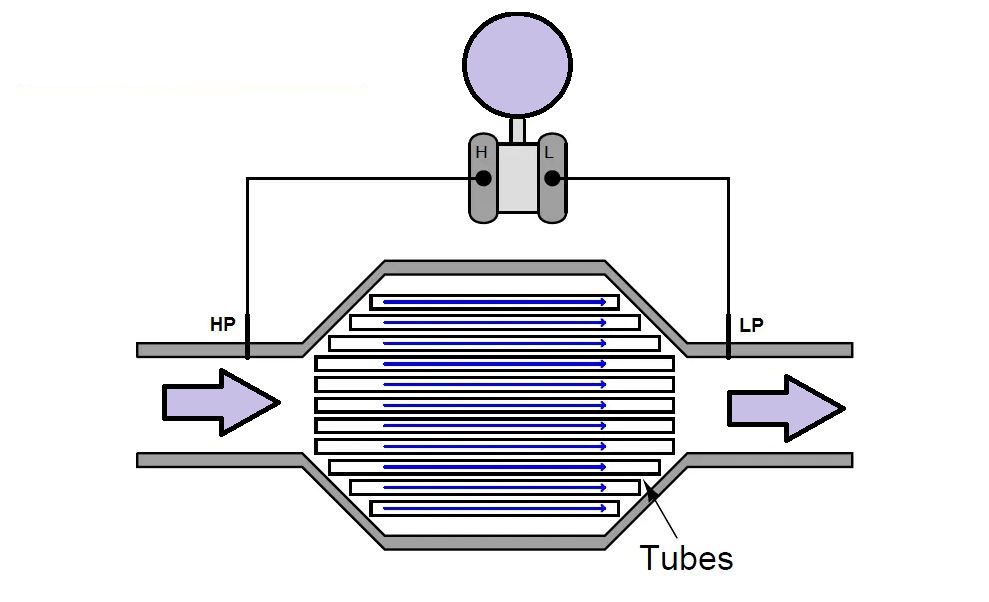

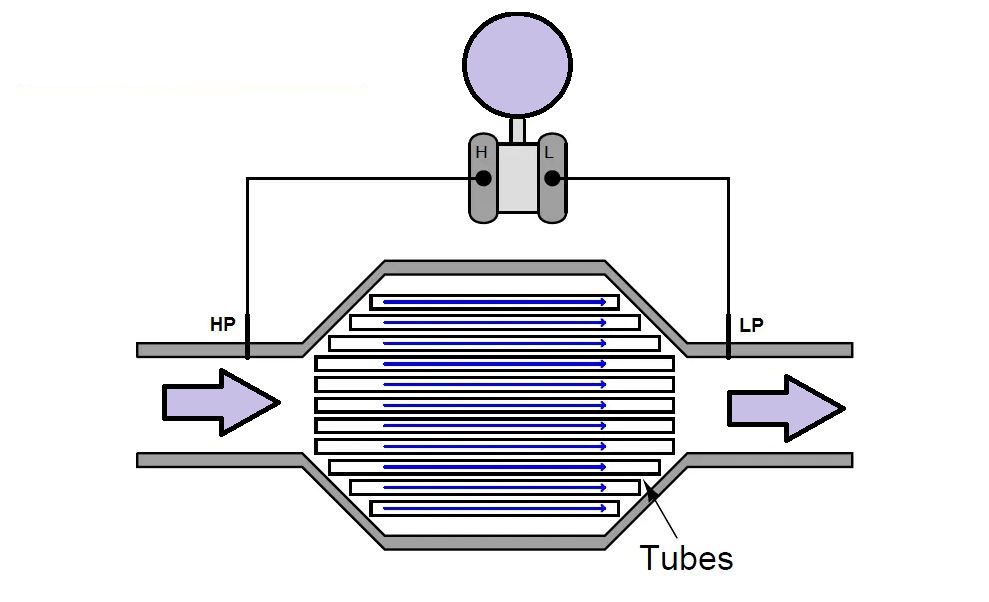

Laminar flow meter elements typically consist of one or more tubes whose length is much greater than the inside diameter, arranged in such a way that a slow flow velocity is generated.

Laminar flow meter

An example is shown here:

The extended diameter of the flow element ensures a lower fluid velocity compared to the pipes entering and exiting the element. This reduces the Reynolds number to the point where the flow regime exhibits laminar behavior.

A large number of small-diameter tubes packed into a wide area of the element provide sufficient wall surface area for the viscosity of the fluid to form an overall pressure drop from inlet to outlet that is measured by a differential pressure transmitter. This pressure drop is permanent (no recovery of pressure downstream) because the mechanism of the pressure drop is friction: total dissipation (loss) of energy in the form of heat.

Another common form of laminar flow element is simply a coiled capillary tube: a long tube with a very small diameter. The small inside diameter of such a tube makes the wall-boundary effect dominant, such that the flow regime will remain laminar over a wide range of flow rates.

The extremely restrictive nature of a capillary tube, of course, limits the use of such flow elements to very low flow rates such as those encountered in the sample networks of some analytical instruments.

Advantages of Laminar Flow Meter

- A unique advantage of the Laminar flow meter is its linear relationship between the flow rate and the pressure drop developed.

- It is the only pressure-based flow measurement instrument for filled pipes that exhibits a linear pressure/flow relationship.

- This means that no “square-root” characterization is necessary to obtain linear flow measurements with a Laminar flow meter.

Disadvantages of Laminar Flow Meter

- The major disadvantage of this type of meter is its dependence on fluid viscosity, which in turn is strongly affected by fluid temperature.

- Thus, all Laminar flow meters require temperature compensation to obtain accurate measurements, and some also use a temperature control system to keep the temperature of the fluid constant as it moves through the element.

Applications of Laminar Flow Meter

- Laminar flow elements find their widest application inside pneumatic tools, where a linear pressure/flow relationship is highly advantageous (behaving like a “resistor” to the tool air flow) and the viscosity of the fluid (the tool air) is relatively constant. .

- Pneumatic controllers, for example, use laminar restrictors as part of the derivative and integral calculation modules, combining the “resistance” from the restrictor and the “capacitance” from the volume chambers to form a type of pneumatic time-constant (τ) network. Huh.

Read Also

- Flowmeter | Flow meter | Flowmeter selection

- Flow Measurement

- Orifice plates Click Here

- Venturi meters Click Here

- Flow nozzles Click Here

- Pitots tubes Click Here

- Annubars Click Here