Table of Contents

A pitot tube is used to measure flow. The pitot tube is an inexpensive alternative to an orifice plate, and its accuracy ranges from 0.5% to 5% FS—the equivalent of a perforation. Its flow range of 3:1 (some operate at 4:1) is also similar to the capacity of the orifice plate. Pitot tubes, such as orifice plates and other differential pressure flow meters, operate on the principles of the Bernoulli equation—which states that as the flow of fluid increases, there is a decrease in pressure.

The main difference between pitot tubes and orifice plates is that, whereas an orifice measures the full flow stream, the pitot tube measures the flow velocity at only one point in the flow stream. An advantage of tapered pitot tube is that it can be inserted into existing and pressurized pipelines (called hot tapping) without the need for shutdown and without unwanted downtime.

Pitot tubes are mainly used for the measurement of fluid velocity. The principle of operation of the pitot tube is based on the fact that, when a solid body is placed centrally and stationary in a pipeline in which the fluid flows downward, the velocity of the fluid begins to decrease due to the presence of the body. until there is zero directly in front of the body. This point is known as the stagnation point. As the kinetic top (pressure) is lost by the liquid, it acquires a stationary top. Thus by measuring the difference between the pressure on the normal flow line and a stagnation point, the fluid velocity is determined.

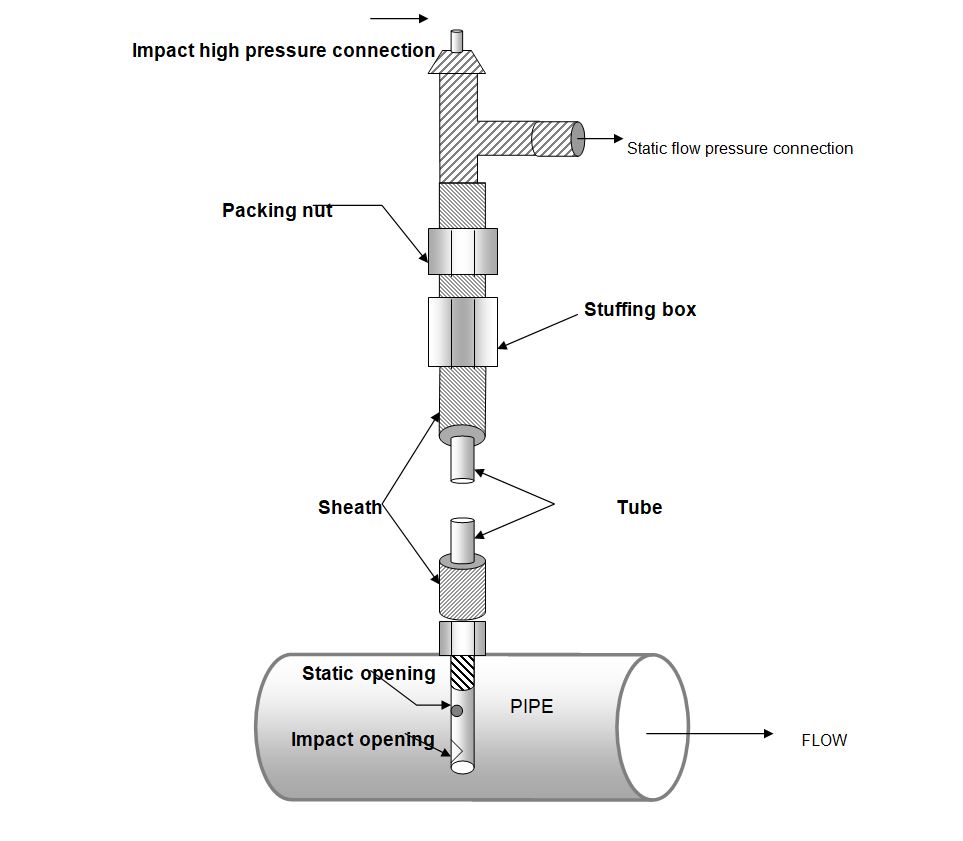

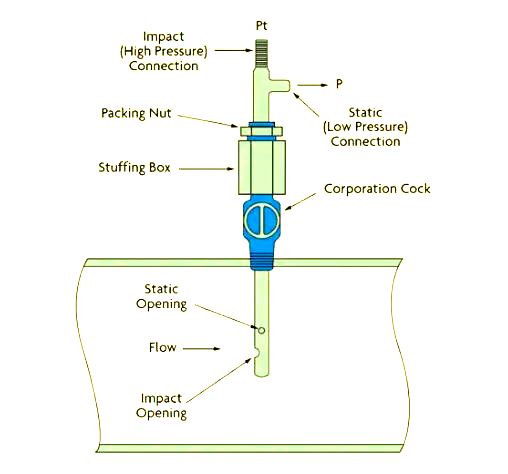

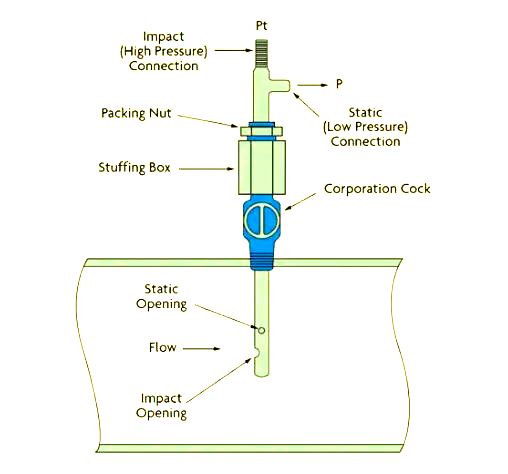

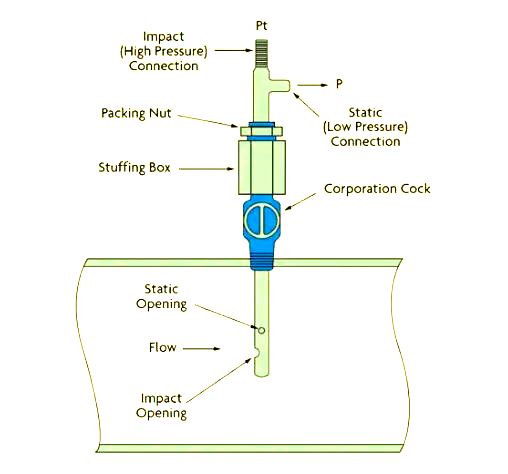

A pitot tube consists of a tube with an impact opening of 3.125 to 6.35 mm that is placed directly in the line of flow, and a stationary opening at 90° from the impact opening. The differential pressure in these tapes is proportional to the velocity of the fluid. The measure of the quantity rate is calculated by the ratio of the average.

Velocity to velocity at the point of measurement. For a precise measurement, the pitot tube is moved across the entire diameter of the pipe to measure the velocity at several points and then the actual average velocity is calculated. The accuracy of pitot tubes can range from +/- to +/- 5%. Pitot tubes are used in process streams but are sometimes used in utility streams where high accuracy is not necessary.

Pitot tube type

Mainly pitot tube are three type that is given below-

Single-Port Pitot Tubes

A single-port pitot tube can measure flow velocity at only one point in the cross-section of a flowing stream (Figure 2). The probe must be inserted into the flowing stream at a point where the flow velocity is the average of the velocities across the cross-section, and its impact port must be directly across the fluid flow. The pitot tube can be made less sensitive to flow direction if the impact port has an internal bevel of approximately 15°, which extends approximately 1.5 in diameter into the tube.

If the pressure difference generated by the venturi is too low for accurate detection, the traditional pitot tube can be replaced with a pitot venturi or double venturi sensor. This will create a high pressure difference.

A calibrated, clean, and properly inserted single-port pitot tube can provide ±1% full-scale flow accuracy over a flow range of 3:1; And, with some loss of accuracy, it can even measure up to a range of 4:1. Its advantages are low cost, no moving parts, simplicity and the fact that it produces very little pressure loss in the flowing stream. Its main limitations include errors arising from velocity profile changes or plugging of pressure ports. Pitot tubes are typically used for flow measurement of secondary importance, where cost is a major concern, and/or when the pipe or duct diameter is large (up to 72 inches or more).

Specially designed pitot probes have been developed for use with pulsating flows. One design uses a pitot probe filled with silicone oil to transmit process pressures to the D/P cell. On high-frequency pulsing applications, oil acts as a pulsating moisture and pressure-averaging medium.

Pitot tubes can also be used in square, rectangular or circular air ducts. Typically, pitot tubes fit through a 5/16-diameter hole in the duct. Mounting can be done by a flange or gland. The tube is usually provided with an external indicator, so that its impact port can be mounted directly into the current. In addition, the tube can be designed to detect the full velocity profile by rapidly and continuously traversing the entire duct.

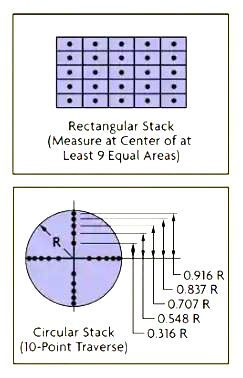

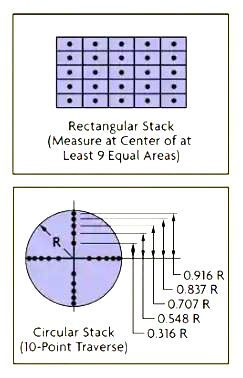

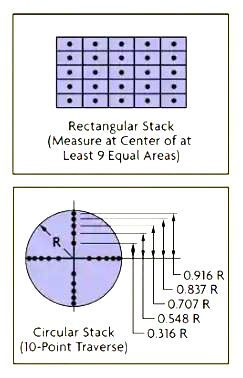

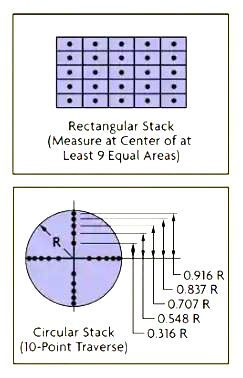

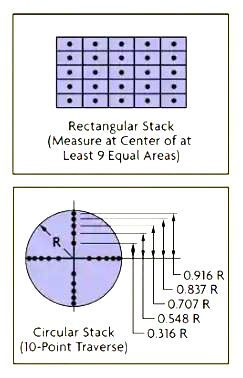

In some applications, such as EPA-mandated stack particulate sampling, it is necessary to pass the pitot sampler across the stack or duct. In these applications, at each point mentioned in Figure 3, a temperature and flow measurement is performed in addition to sampling the gas, the data of which is then combined and taken to the laboratory for analysis. In such applications, a single probe consists of a pitot tube, a thermocouple and a sampling nozzle.

Average pitot tubes

Average pitot tubes have been introduced to overcome the problem of finding the average velocity point. The pressures detected by all effect (and all constant by varying) pressure ports are summed up and the square root of their difference is measured as an indication of the average flow in the pipe (Figure 4). The port closer to the outlet of the combined signal has a slightly greater effect than the farthest port, but for secondary applications where pitot tubes are typically used, this error is acceptable.

The number of impact ports, the distance between ports, and the diameter of the average pitot tube can all be modified to match the needs of a particular application. The sensing ports in average pitot tubes are often too large to allow the tube to behave as a true average chamber. This is because the sizable port openings are optimized not to average, but to prevent plugging. In some installations, purification with an inert gas is used to keep the ports clean, allowing the sensor to use smaller ports.

Average pitot tubes offer the same advantages and disadvantages as single-port tubes. They tend to be a bit more expensive and a bit more accurate, especially if the flow is not completely formed. Some average pitot sensors can be inserted through the same opening (or hot tap) that accommodates a single-port tube.

Area-averaged pitot

Area-averaged pitot stations are used to measure large flows of low-pressure air in a boiler, dryer or HVAC system. These units are available for various standard sizes of circular or rectangular ducts (Figure 5) and pipes. They are designed in such a way that each section of cross-section is provided with both an impact and static pressure port. Each set of ports is connected to its own manifold, which aggregates the average constant and average impact pressure signals. If plugging is likely, the manifold can be purged to keep the ports clean.

Since area-averaged pitot stations produce very small pressure differences, it may be necessary to use low-difference D/P cells with spans as low as 0–0.01 in the water column. To improve accuracy, a hexagonal cell-type flow straightener and a flow nozzle can be installed upstream of the area-averaged pitot flow sensor. The flow straightener removes local turbulence, while the nozzle increases the differential pressure produced by the sensor.

Pitot tube Advantage

- No process loss.

- Economical to install.

- Some types can be easily removed from the pipe line.

Pitot Tube Disadvantage

- Have poor accuracy.

- Unsuitability for dirty or sticky fluids.

- Sensitivity to up stream disturbances.

Read Also