Table of Contents

There are various types of strain gauge sensors widely used in industries. A broad classification is shown as follows-

- Wire wounded strain gauges

- Bonded wire strain gauge

- Unbonded strain gauge

- Foil strain gauge

- Semiconductor strain gauges

- Capacitive strain gauges

- Strain Gauge Rosettes

Note- Here we will discuss wire wounded strain gauge. for other type please click on links given at the end of paragraph.

Wire wounded strain gauges

Wire wounded strain gauge consist of a thin resistance wire which is either stretched or firmly bonded on an insulating sheet of a paper, tissue, Bakelite or Teflon etc. When this is attached to an object whose stress or strain to be measured, a small change in strain results into change in dimension of wire, hence resistance change is produced. Here resistance wire can be made of metals, semiconductors or alloys. Selection of material of wire is determined based on the properties such as-

- Application for which it is to be used

- Adhesive properties for bonded type gauges

- Stress-strain properties of wire

- Strain sensitivity

- Resistance temperature sensitivity etc.

Strain Gauge Wire material-

There are various resistance materials available to construct strain gauge. Gauge wires are made up of metals, or alloys. Some of them are as follows-

- Constantan

- Nichrome

- Dynalloy

- Platinum alloy

- Copper Nickel

- Nickel Chrome

- Nickel Iron

- Modified Nickel Chrome

- Platinum Tungsten, etc.

Wire Strain Gauge Types-

Based on their structure, wire strain gauge can be classified as-

- Bonded type strain gauge

- Unbonded type strain gauge

Bonded type strain gauge

In bonded strain gauges, a fine resistance wire of diameter 0.25mm or less is bonded or pasted on a thin flexible sheet of a paper, tissue, Bakelite or Teflon etc. and this substrate or sheet is directly attached using adhesive to the surface of the structure whose stress or strain to be measured. A diagram of bonded strain gauge is shown as follows-

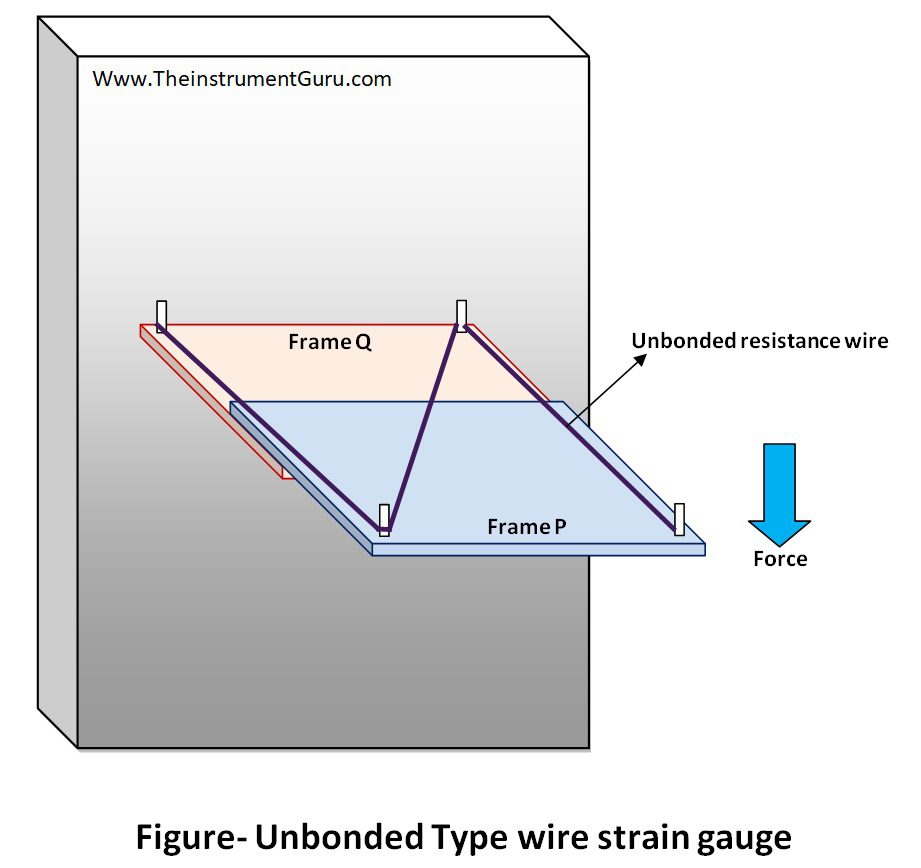

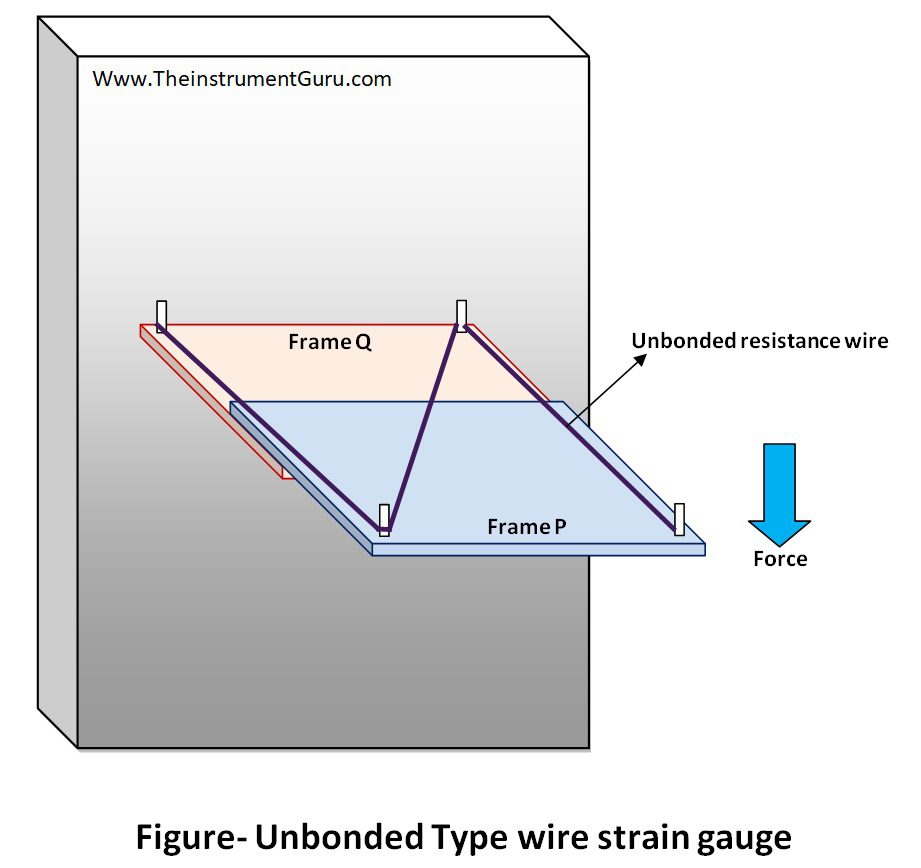

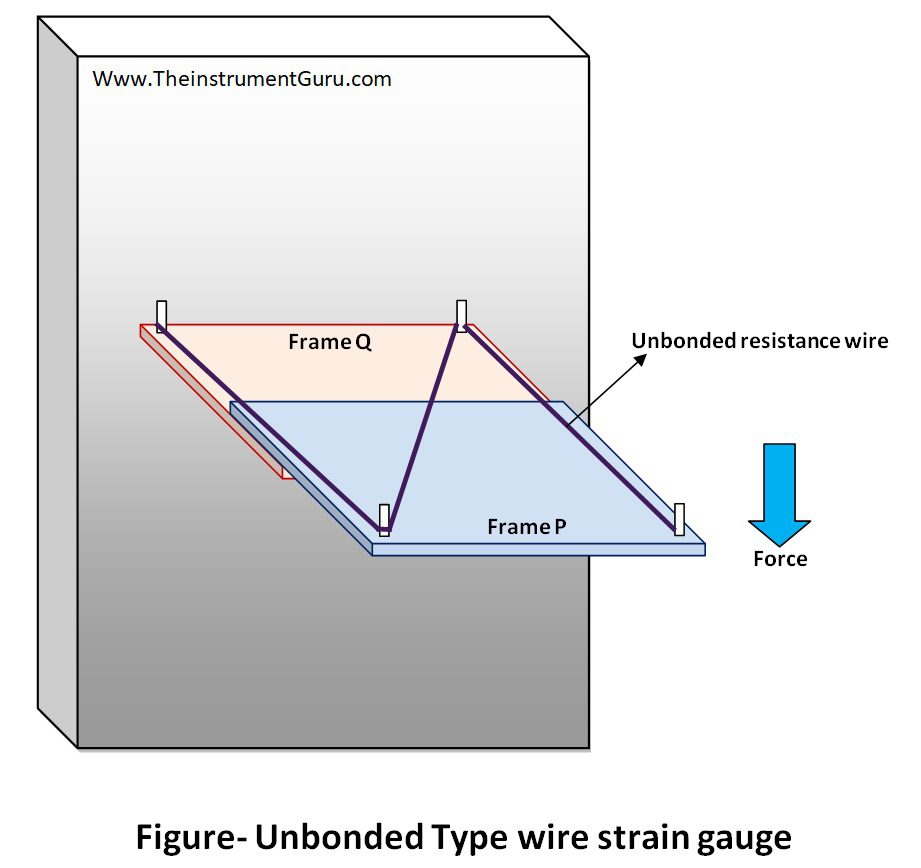

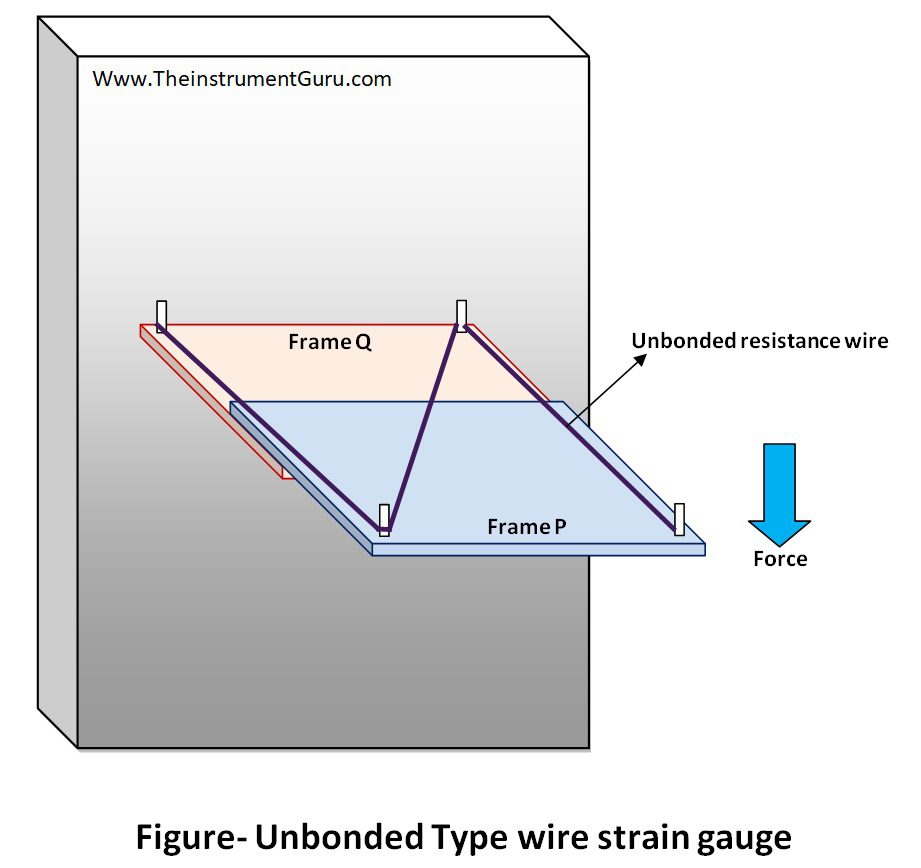

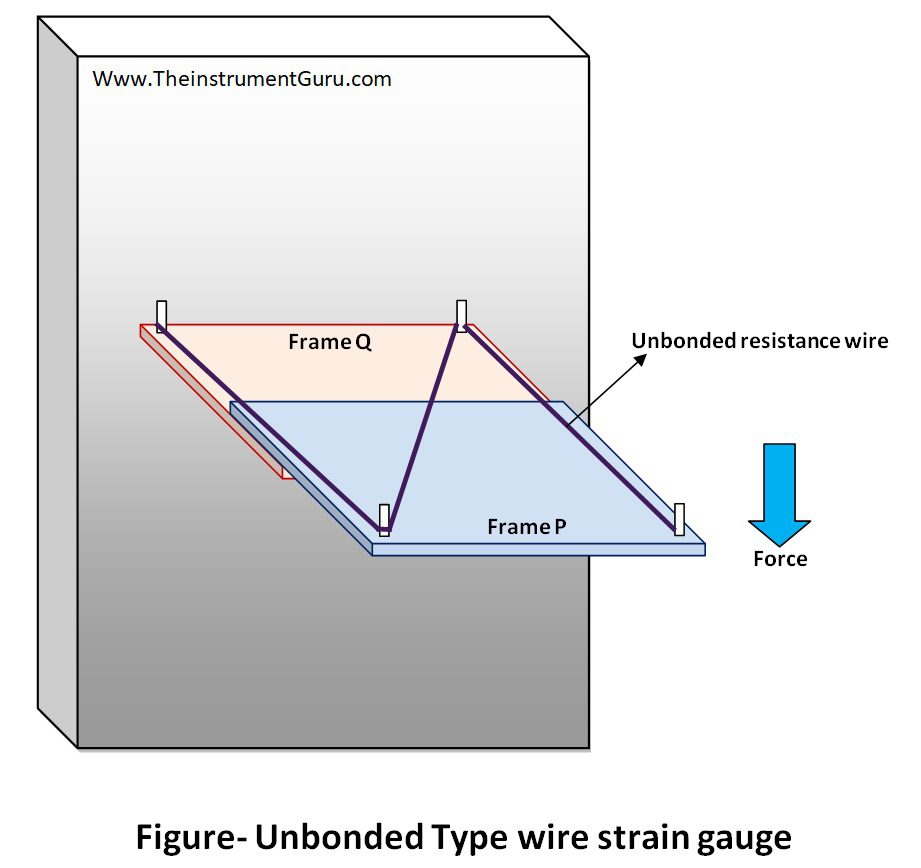

Unbonded strain gauge

In Unbonded strain gauge, fine resistance wire of diameter 0.003mm or less is stretched between two frames P & Q using insulated pins. The major difference between bonded and unbounded strain gauge is that resistance wire is not directly bonded here on the surface of the structure under stress analysis. There can be various configuration possible to stretch gauge wire. A diagram showing unbounded strain gauge is shown as follows-

To read more about other strain gauge types click on individual links here-

- Bonded strain gauge

- Unbonded strain gauge

- Foil strain gauge

- Semiconductor strain gauges

- Strain Gauge Rosettes

- Gauge Factor

- Stress – Strain Curve