Table of Contents

Primary sensing elements are the primary instrument of pressure sensor. They change its state and indicate pressure at calibrated scale. Primary sensing elements like manometer and others are as follows:

Manometer

Manometer is used to measure low pressure. Manometer are widely used in process application in industry . They are primary standard for pressure measurement. It is used to measure Low vacuum range to approximately 1000 mm of Hg. A wide variety of fluid are used for manometers, their specific gravity range well below from 1.0 to 13.5707 the sp. gr. of Hg. These are simple time proven construction, high accuracy good repeatability wide range of fluid. It is used as a primary standard working device. There are general three types of manometers. They are ‘U’ tube manometers, Well Type manometers and inclined Manometer.

Bourdon Tube

Most common pressure measuring Instrument working based on elastic deformation. Design of the bourdon mainly in three shape The ‘C’ , the spiral and the helical .They are widely used for local indications and for signal transmission to remote locations also adopted to transducer designs for obtaining electrical output. Bourdon tubes are made of the materials phosphor bronze, beryllium copper, 4130 alloy steel. 316 &403 ss, K-monel, monel and Ni-span C. The choice of material depend upon the process medium, pressure range, temp. corrosiveness etc. the operating range from 30 inches Hg to 100000 psi or higher or special applications

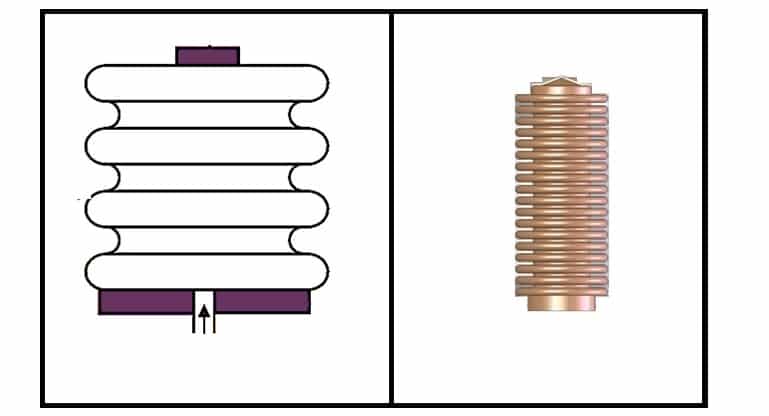

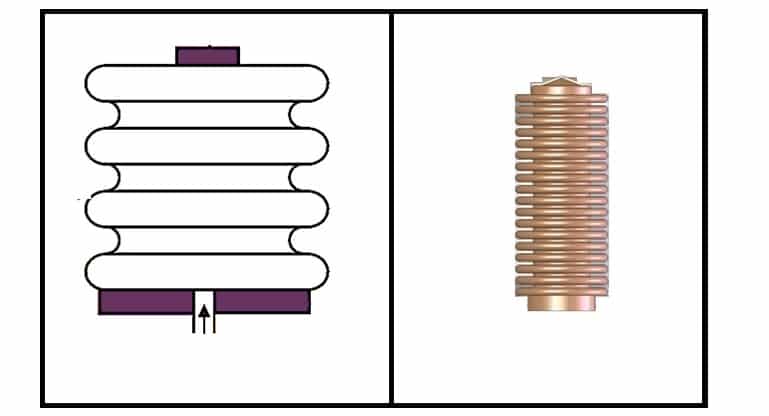

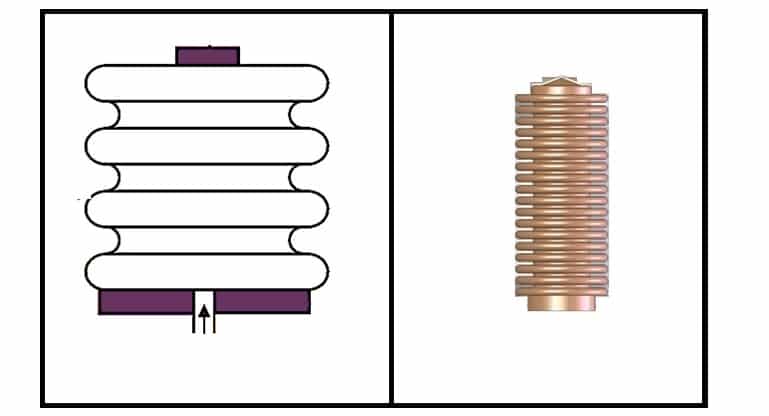

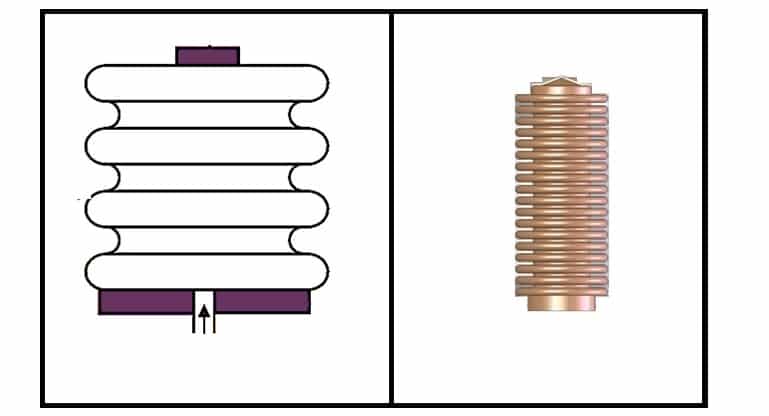

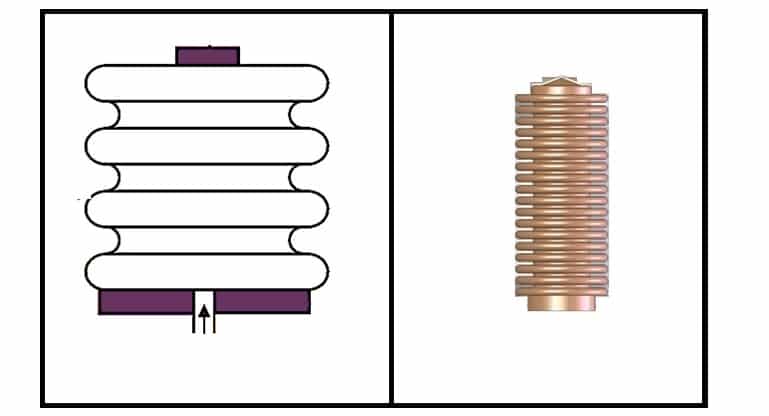

Bellows and Capsules :-

Pressure measuring elements are used to measure absolute, gauge or differential pressure, some time used in pressure transmitters ( as the bellow expands due to pressure in turn exert force on lower end of force of pneumatic/ electronic transmitter . The reduction of drift and hysterics allow their use in functions requiring 0.5% full span accuracy .. They extend to medium pressure ranges 0-400 psi of DP and 6000 psi in static pressure range.

Diaphragm

The operating principle is similar to that of bellows. The applied pressure causing it to expand it directly in proportion to the applied pressure. Diaphragm is a flexible disc with flat or corrugated surface used in measuring absolute pressure. vacuum gauge pressure. and similar to the bellows these are used in electrical & pneumatic transducers. Their pressure ranges extended to 10000 psi with temp. 800 deg. F & also higher range of special applications. The accuracy + – 0.5% of full span up to pr.15000 psi. Material of construction includes phosphore-bronze, baryllium-copper, SS Inconel, Hasteloy Nickel and also in non metal Bunna N rubber, nylon Teflon etc non metallic diaphragm used below 1500 psi. Accuracy range from 0.5% 25% of span.

Electronic Transducer / Transmitters ;-

Most electronic pressure sensors incorporate with one of the primary pressure detector used to vary a measurable electrical quantity to produce a proportionately variable electronic signal. Among the electronic device used to measure the pressure are Strain gauge, Load Cell, inductive, capacitive, piezoelectric transducer linear variable differential transformer. The electronic detector are more accurate, much faster response time .Though these are costing high but reduced movement very nearly eliminates drift, frictions and hysteresis as compared to bellow, diaphragm & bourdon instrument

Strain gauge:

Strain is define as a deformation or change in shape of a material as a consequence of applied force. A strain gauge is a device which uses the change of electrical resistance of a wire under strain to measure pressure ie. mechanical motion into electrical signal. generally strain gauge inst. accuracy is +/- 0.1% of full scale span & range few inches H2O to 20000 psig Accuracy +/-0.5% of full span.

Read Also

- Bourdon Tube pressure gauge

- Bellows pressure gauge in Hindi

- Bellows Pressure Gauge

- Pressure transmitter in hindi