In a simple closed loop control system, corrective action takes place after the disturbance has affected the controlled condition and this is termed feedback. On the other hand, in a control system where corrective action is taken immediately, the disturbance occurs without waiting for it to penetrate through the time leg of the process and affecting the controlled condition, the system is termed feedforward. Obviously to apply corrective action in this fashion the disturbance must be detected and measured.

Consider the example of a heater as shows in fig….. below. The disturbance, being a change in demand, is measured by detecting the flow with an orifice plate and signal applied to a summation relay. Under steady conditions of demand, the temperature will be controlled in the normal closed loop and feedback manner, but as soon as there is a change in demand, there would be an immediate corrective action by opening or closing of the steam control valve accordingly . The immediate corrective action, i.e the feed forward action, need only be approximate as it is subsequently ‘trimmed ‘ by the action of the controller. In general terms, with feed forward control it is implicit that a knowledge of offset of a disturbance and the required corrective action is known.

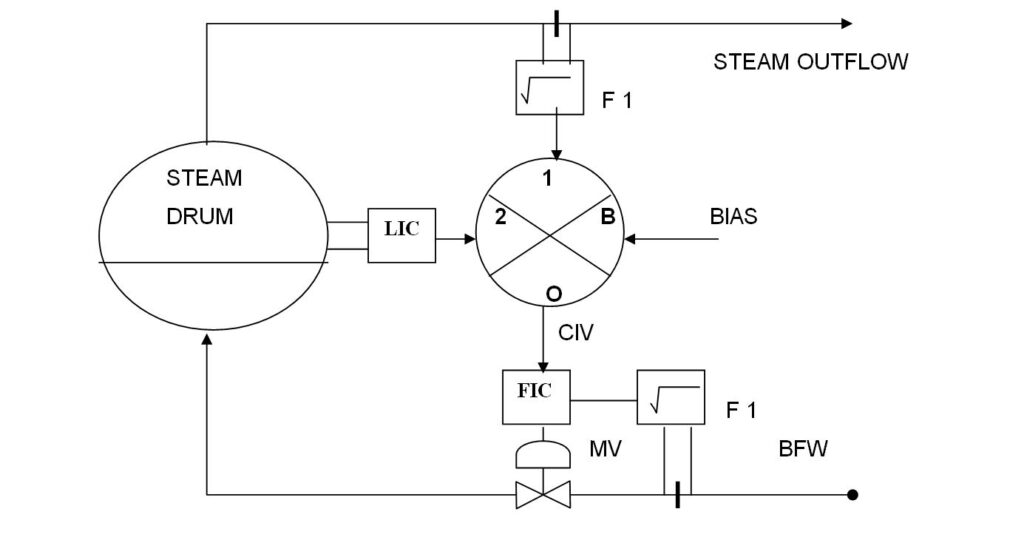

An another popular example of feed forward control, which is generally used in most of the large production capacity and power producing industries is STEAM DRUM LEVEL CONTROL.

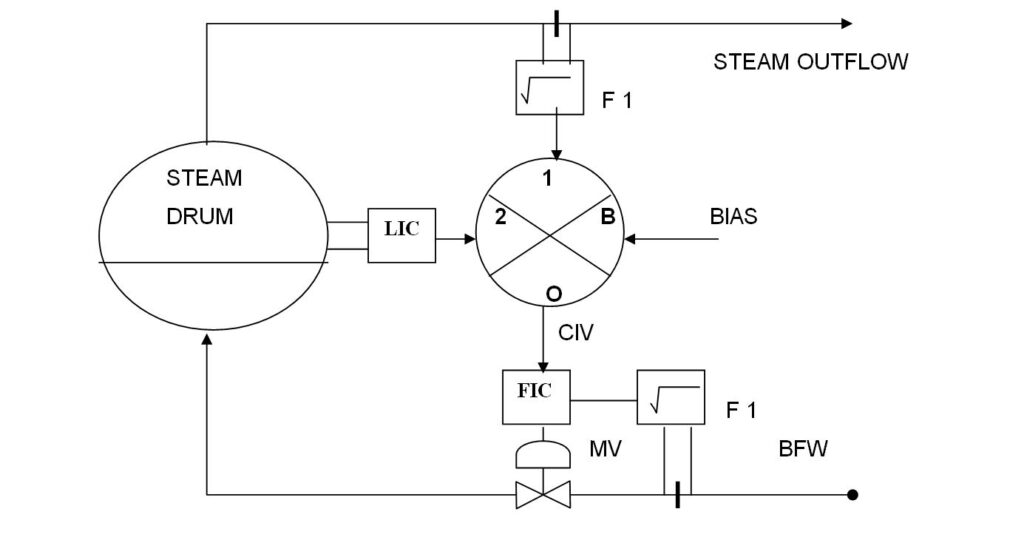

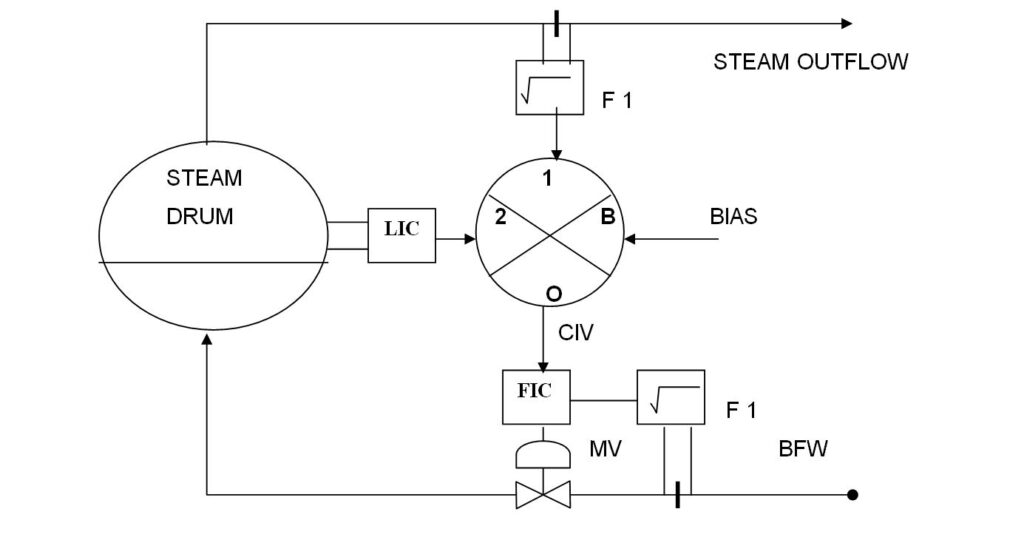

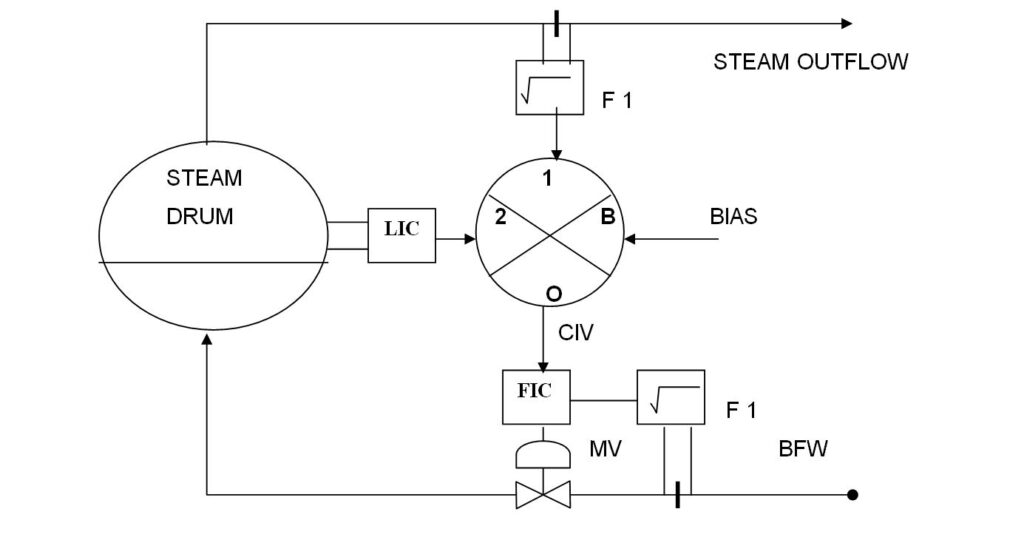

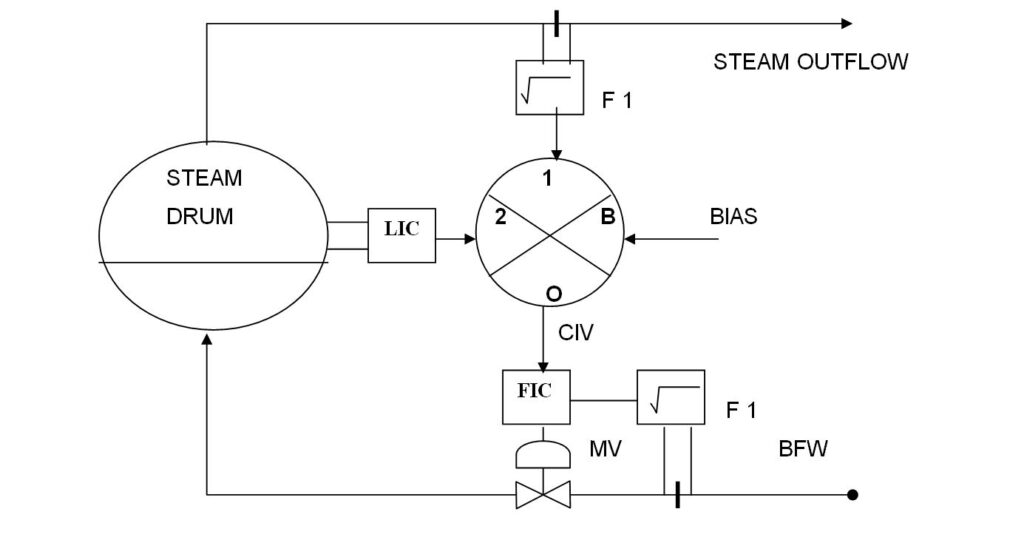

Feedforward control Loop In Steam Drum Level

In a feedforward control system information concerning on coming disturbance is fed forward to the regulating element before it, the disturbance, reaches the system under control and so the effects of the disturbance are reduced. Combined with cascade and feed back, feed forward can give a 100 to 1 % improvement in a difficult control situation. Atypical operation will will serve to make the point clear.the control of boiler drum level is critical in a steam plant because of the inter dependence of pressure, temperature, inflow and out flow.

A flow meter on the boiler feed water via a square root extractor provides the measured variable signal for the three term controller which protect the feed water flow and hence the drum level against changes in feed water pressure . the set point of this controller is cascaded from the summing relay whose output is input 1 minus input 2 plus the bias. The output of the steam out flow flow meter with square root extraction and suitably scaled is sent via the summing relay direct to the set point of the feed water Flow controller so that inflow constantly matches outflow with minimum affect on boiler level. A level transmitter and controller on the level drum provides a feed back path to make small corrections to the set point of the feed water flow controller for losses and gain to the drum level from other parts of the point. The same remarks about derivative action apply to the level controller as did for the master controller in the straight cascade system.

Read Also

- How to control boiler drum level

- Hydraulic Control System

- Controllers | Configuration of a controller

- Electronic Control System