Table of Contents

Bourdon Tube pressure gauge:- The Bourdon tube is the most commonly used pressure gauge because of its simplicity. It is in C – shape. These cover Ranges from 0 – 15 PSIG To 0 – 100000 PSIG as well as vacuum from 0 to 30 inches of Mercury.

Bourdon tubes are circular shaped tubes with an oval cross section bourdon tubes are manufactured in three different forms they are C- type, spiral type and helical type

- Bourdon tube sensing elements are used for measurement of medium to high pressures.

- Without pressure the circular cross section of the bourdon tube is flatted.

- When these elements are pressurized their cross section tends to become more circular which tends to straighten their shape.

C- Type bourdon tube pressure gauge

The pressure input is given to a socket which is soldered to the tube on the base. The free end of the device is sealed by a tip. This tip is linked to a segmental lever via an adjustable size link. The lever size might also be adjustable. The segmental lever is suitably pivoted and the spindle holds the pointer as proven within determine. A hair spring is usually used to fasten the spindle of the body of the instrument to supply needed tension for correct meshing of the gear tooth and thereby freeing the system from the backlash. Any error as a consequence of friction within the spindle bearings is known as lost motion. The mechanical construction needs to be extremely accurate within the case of a Bourdon Tube Gauge. If we think about a cross- section of the tube its periphery may have a larger surface than the inside portion. The tube walls may have a thickness between 0.01 and 0.05 inches.

When pressurized fluid enters the bourdon tube, it tries to change the section of the tube from oval to circular and this tends to straighten out the tube. The resultant movement of the free end of the tube causes the pointer to move up the scale. Tip of the bourdon tube is connected to segmental lever through an adjustable link. To which the pointer is attached and Borden moves on a calibrated scale with the movement of the tube as the pressure increases.

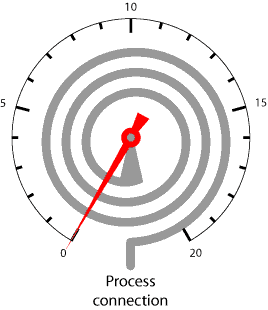

Spiral Bourdon tube pressure gauge

Since the free end speed of C-type Bourdon tube is insufficient in some cases, spiral type Bourdon tube is used. The spiral element is essentially a series of C type tubes that, when pressure is applied, this flat spiral produces greater movement of the free end without requiring any mechanical amplification. This increases the sensitivity and accuracy of the tool as no lost motion or friction is introduced through the links and levers.

Spans of as low as 10 psi are available for positive negative ranges.

Helical Bourdon tube pressure gauge

This sensor produces an even greater speed of the free end than the spiral element eliminating the need for mechanical amplification. The range of a helical coil is affected by diameter, wall thickness, number of coils used, and construction material. High pressure elements may have 20 coils while low span sensors may have only 2 or 3 coils. Helical elements are available with periods ranging from 0 to 30 psi to 0 to 80,000 psi.

Design Pressure

Up to 100000 PSIG (690Mpa)

Design Temperature

Up to 600 oF (316 oc) with stainless steel bourdon tube.

Materials of Construction

Phosphor Bronze, Alloy Steel, 316 & 403 Stainless Steel, Beryllium Copper, Monel, Ni-Span Si

Range:

Minimum span 15 PSI (100 kPa); maximum span 100,000 PSI (690 MPa).

Advantage and disadvantage of helical pressure Gauge

There are some advantage and disadvantage of helical pressure gauge that is given below-

Advantage

- Increased accuracy and sensitivity.

- Higher over range protection

Disadvantage

Very expensive as compared to other types of pressure gauge.

Read Also