Table of Contents

Structure-

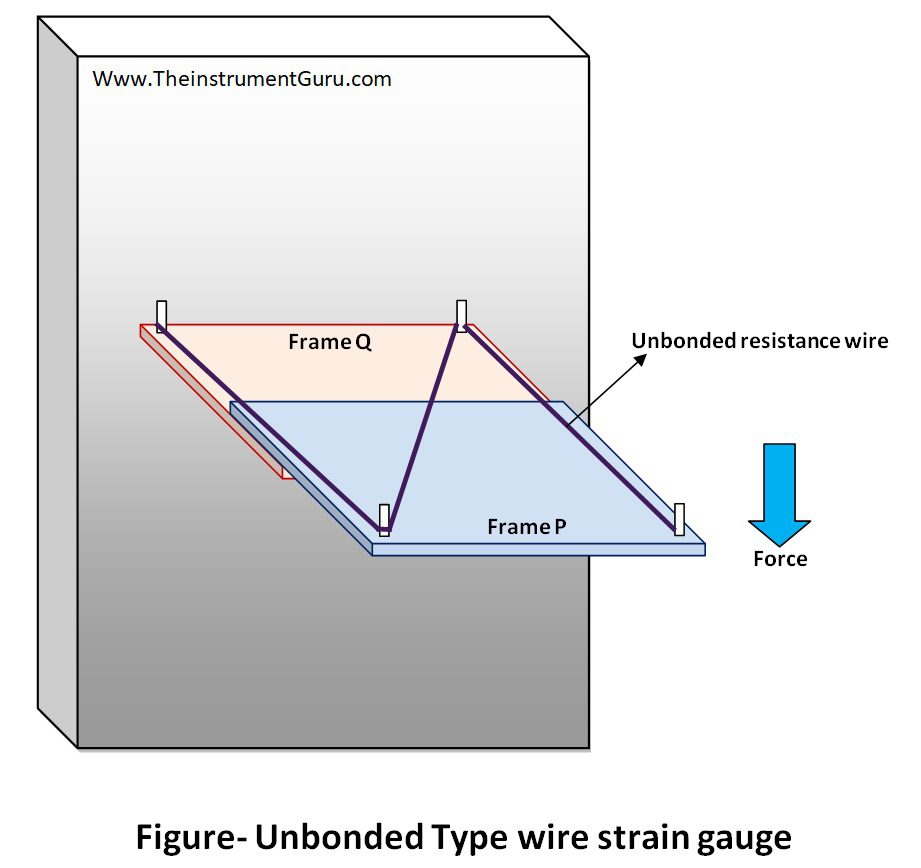

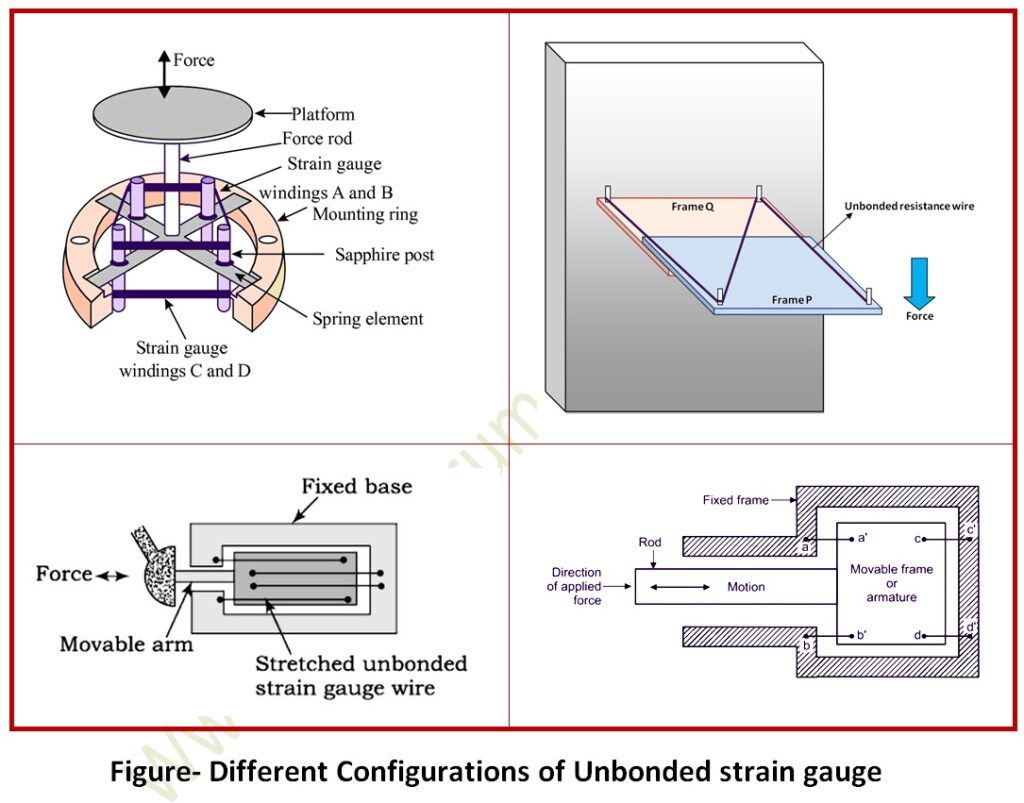

In Unbonded strain gauge, fine resistance wire of diameter 0.003mm or less is stretched between two frames P & Q using insulated pins. Here both the frames can move relative with respect to each other and are held together by a spring loaded mechanism. Gauge wire is connected to one arm of wheat stone bridge network. The major difference between bonded and unbounded strain gauge is that resistance wire is not directly bonded here on the surface of the structure under stress analysis. There can be various configurations possible when changing method to stretch gauge wire. A diagram showing unbounded strain gauge is shown as follows-

Working Principle-

Principle of operation is similar to bonded type strain gauge. When frame P is subjected to a force, pressure, weight etc., frame P get shifted slightly downward hence gauge wire gets elongated, which causes a change in resistance that can be detected and measured by bridge circuits and can be calibrated in unit of measurement of process variable such as force, pressure, weight etc.

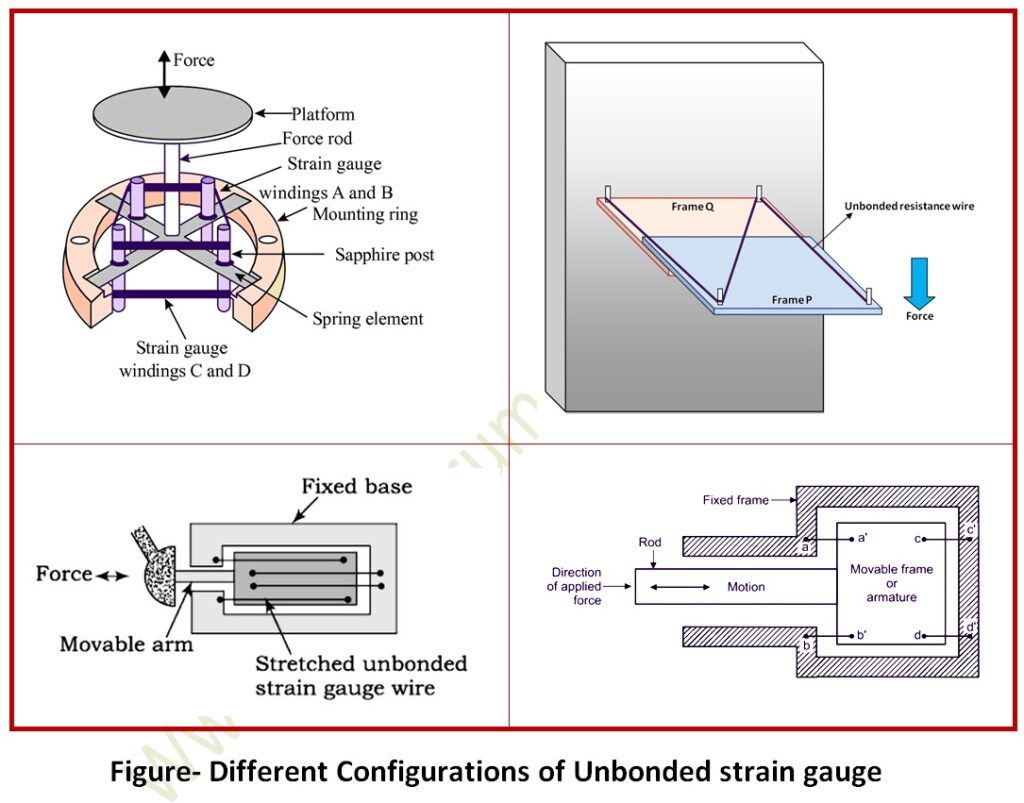

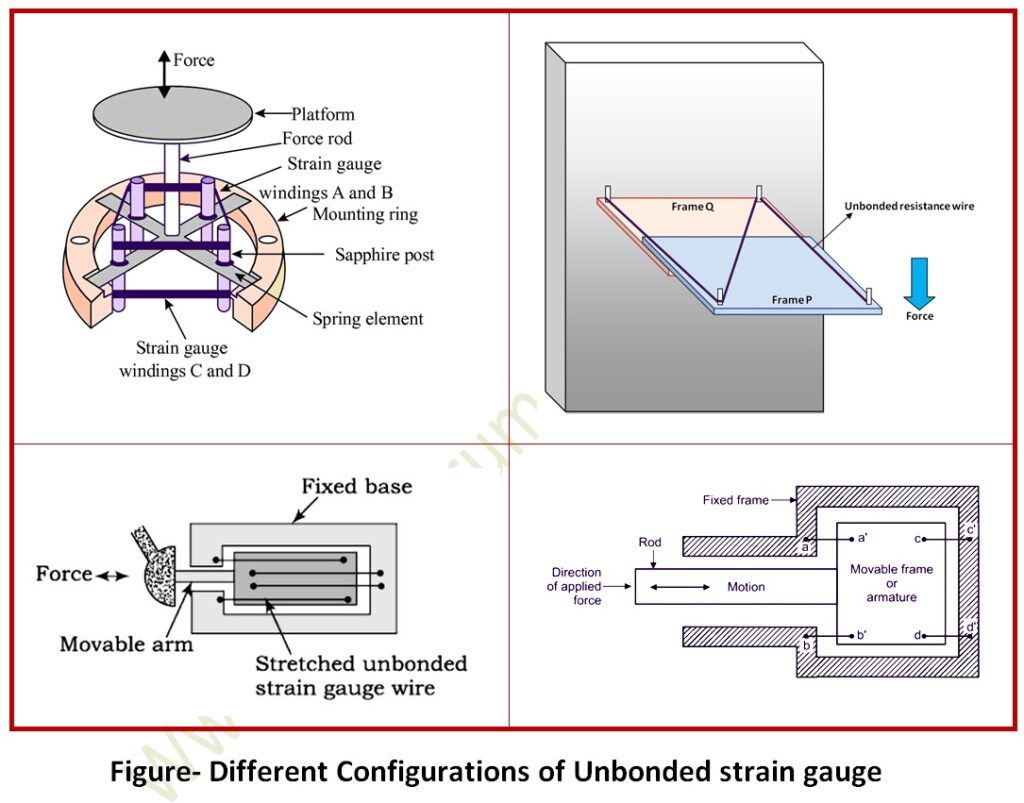

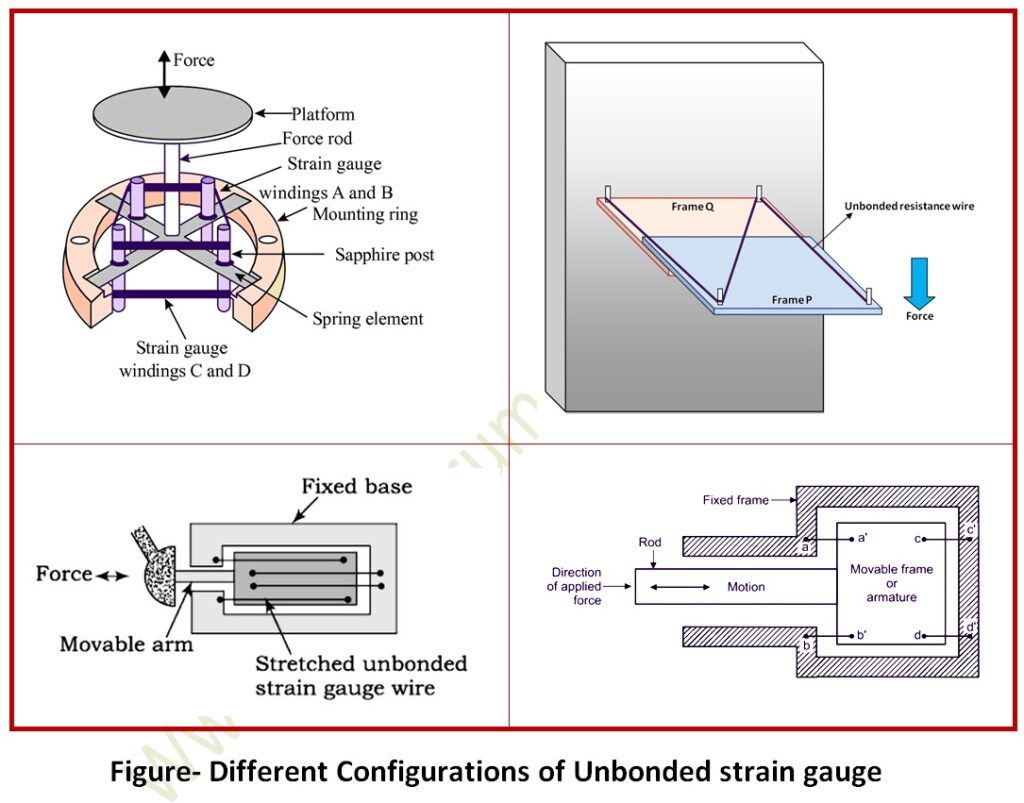

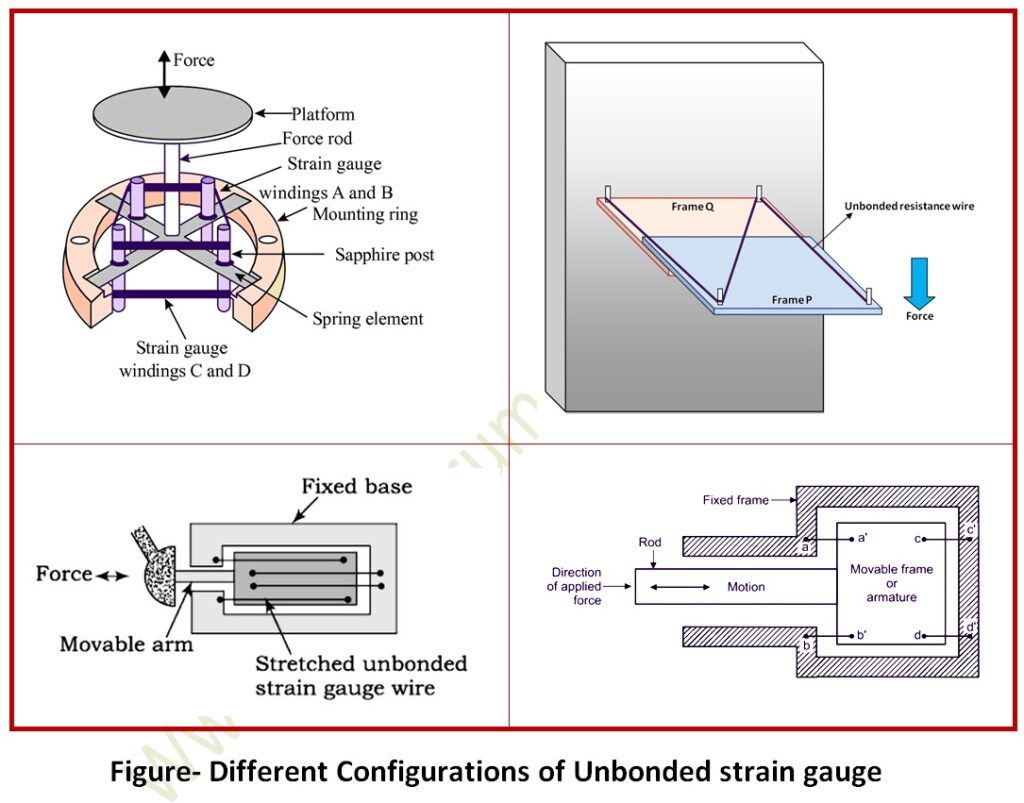

Configurations-

There are numerous configurations possible either by changing wire stretching method, or by changing a primary sensing element such as diaphragm or solid plate or dome etc. A figure showing different configuration of unbounded strain gauge is shown below-

Advantages-

- They are available in simple configuration and small size.

- They are having low hysteresis.

- Unbonded gauges can be used in high temperature installations as there is no bonding or organic material present.

- They are used for force, strain, weight, load, pressure and displacement etc.

- They are used in accelerometers to measure acceration.

Strain Gauge Wire material-

There are various resistance materials available to construct strain gauge. Gauge wires are made up of metals, or alloys. Some of them are as follows-

- Constantan

- Nichrome

- Platinum alloy

- Copper Nickel

- Nickel Chrome

- Nickel Iron

- Modified Nickel Chrome

- Platinum Tungsten, etc.

Unbonded Strain Gauge Specification-

- In unbonded gauges range of resistance can be typically 120 Ω to 1000 Ω.

- Normal operating voltage range 5V to 10V

- These are mostly used in such applications where force, strain, displacement etc. are to be measured frequently.

To read more about other strain gauge types click on individual links here-

- Types of Strain gauge

- Bonded strain gauge

- Foil strain gauge

- Semiconductor strain gauges

- Strain Gauge Rosettes

- Gauge Factor

- Stress – Strain Curve