Table of Contents

Diaphragm Level Switch

Diaphragm level switch is sensor with an electrical contact output. When material in the bin exceeds the level of the diaphragm level switch, a sensitive micro-switch is activated. It sends an alert that can be utilised to initiate or halt a process or alarm in the vessel. Diaphragm Level Switch are frequently utilised in grains, feed, seeds, and other granular materials. Applications include mining, silos, hoppers, and food & beverage.

Working Principle Diaphragm Level Switch:

“One of the limit switches inside the switch chamber is activated by the product’s pressure on the membrane(Diaphragm). The limit switch’s contact is utilised to initiate control action.”

The Diaphragm Type Level Switch is a level switch detecting an object to be measured, through utilizing the pressure change affected by level rise and fall in a pipe. As level rises, air pressure inside a pipe gets higher. When the measuring face of diaphragm falls under the air pressure, the diaphragm presses a micro switch, thus turning it on. In turn, as the level descends and the air pressure inside the detection pipe gets lower, the output contact will return to the initial condition.

Application of Diaphragm Type Level Switch

For noticing material on the screw conveyor is clogged.

To detection of the bucket elevator’s boot level.

For checking the amount of food grain in the hopper.

For bulk goods, level detection.

To detects bin overflow and keeps the material level at a certain level.

Advantages of Diaphragm Type Level Switch

Point Level switch.

Cheap but dependable

No power source is necessary.

It’s easy to install.

Non-intrusive flush mount

ideal for situations when vessel size, internal clearance, or protrusion into a vessel are restricted.

It provides Screw conveyor over-pressure protection.

Read Also:-

Remote seal DP transmitter Calibration

Related Search:-

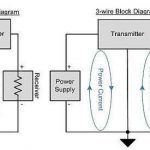

4-20 mA Transmitter Wiring Types: 2-Wire, 3-Wire, 4-Wire

4-20 mA Transmitter Wiring Types: 2-Wire, 3-Wire, 4-Wire

How to check linearity of vibration probe(Axial&radial)

How to check linearity of vibration probe(Axial&radial)

Flow switches

Flow switches

Actuators

Actuators

Two out of three (2oo3) Logic

Two out of three (2oo3) Logic