Table of Contents

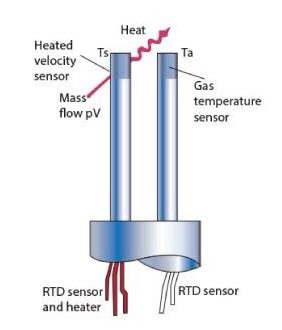

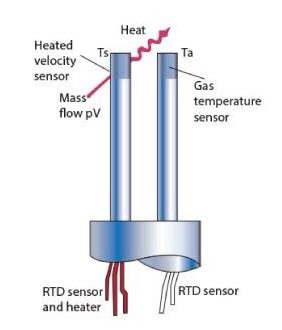

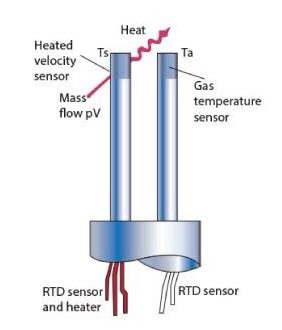

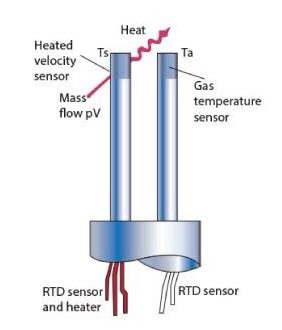

A thermal mass flow meter is a device used to measure the flow rate of a fluid, typically a gas, by detecting the heat transfer between the fluid and a heated sensor. The principle behind the operation of a thermal mass flow meter is based on the fact that as a fluid flows past a heated sensor, it absorbs some of the heat, which can be measured to determine the flow rate. The thermal mass flow meter consists of a heated sensor that is placed in the fluid stream and a temperature sensor that detects the change in temperature of the fluid as it flows past the heated sensor. The temperature difference is proportional to the mass flow rate of the fluid, which is then used to calculate the flow rate. The thermal mass flow meter is commonly used in various industries, including chemical processing, oil and gas, and environmental monitoring, where accurate measurement of gas flow rates is crucial. It offers several advantages over other flow meters, such as high accuracy, low pressure drop, and the ability to measure flow rates in low-pressure systems.

Working principle of Thermal mass flow meter:-

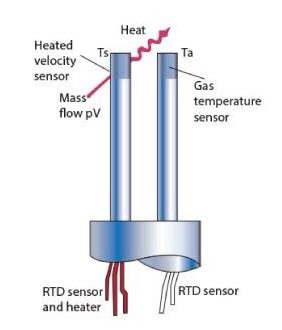

The working principle of a thermal mass flow meter is based on the heat transfer between a heated sensor and a fluid flowing over it. The device consists of two temperature sensors and a heater placed in a flow stream. The first temperature sensor is placed upstream of the heater, and the second temperature sensor is placed downstream. The heater is heated up to a set temperature and is maintained at a constant temperature. As the fluid flows over the heater, it absorbs some of the heat from the heater. The first temperature sensor measures the temperature of the fluid upstream of the heater, and the second temperature sensor measures the temperature of the fluid downstream of the heater. The temperature difference between the two sensors is proportional to the mass flow rate of the fluid. The amount of heat transferred from the heater to the fluid is proportional to the mass flow rate, and the temperature difference between the two temperature sensors is directly proportional to the amount of heat transferred. By measuring the temperature difference between the two temperature sensors, the thermal mass flow meter can accurately determine the mass flow rate of the fluid. The device can be calibrated to measure the flow rate of a specific gas or fluid at a particular temperature and pressure.

Formula of thermal mass flow:-

The formula for a thermal mass flow meter is based on the principle of heat transfer and the specific heat capacity of the fluid being measured. The formula is:

Q = K * ∆T

where:

- Q = Heat transfer rate (W)

- K = Thermal conductivity of the fluid (W/mK)

- ∆T = Temperature difference between the upstream and downstream temperature sensors (°C)

The mass flow rate (m) of the fluid can be calculated from the heat transfer rate and the specific heat capacity of the fluid (Cp) using the formula:

m = Q / (Cp * ∆T)

where:

m = Mass flow rate (kg/s)

Cp = Specific heat capacity of the fluid (J/kg.K)

The flow rate (V) of the fluid can be calculated from the mass flow rate and the density (ρ) of the fluid using the formula:

V = m / ρ

where:

V = Flow rate (m/s)

ρ = Density of the fluid (kg/m^3)

These formulas can be used to calculate the flow rate of a fluid based on the temperature difference measured by the thermal mass flow meter, the specific heat capacity of the fluid, and the density of the fluid.

Types of Thermal mass flow meter:-

There are two main types of thermal mass flow meters:

-

Insertion Type Thermal Mass Flow Meters:-

Insertion type thermal mass flow meters have a probe that is inserted into a pipeline or duct to measure the flow rate of the fluid. The probe contains a heated element, which is placed in contact with the fluid, and two temperature sensors, which measure the temperature difference between the heated element and the fluid. Insertion type thermal mass flow meters are typically used in large pipelines or ducts where the fluid flow rate is high and where the cost of installation is an important factor.

-

Inline Type Thermal Mass Flow Meters:-

Inline type thermal mass flow meters have a sensor built into the pipeline or duct and measure the flow rate of the fluid as it flows through the sensor. The sensor consists of a tube or a bypass flow path containing a heated element and two temperature sensors. Inline type thermal mass flow meters are typically used in smaller pipelines or ducts where the fluid flow rate is low and where high accuracy is required.

Application of Thermal mass flow meter:-

Thermal mass flow meters are used in a wide range of industrial applications where the accurate measurement of gas flow rates is critical. Some common applications of thermal mass flow meters include:

- Chemical Processing: Thermal mass flow meters are used to measure gas flow rates in chemical processing plants to ensure accurate control of chemical reactions, optimize production efficiency, and maintain product quality.

- HVAC Systems: Thermal mass flow meters are used in HVAC systems to measure the flow rate of air and other gases to control the temperature, humidity, and ventilation in buildings.

- Power Generation: Thermal mass flow meters are used to measure gas flow rates in power generation facilities to ensure efficient operation and reduce emissions.

- Environmental Monitoring: Thermal mass flow meters are used in environmental monitoring to measure gas flow rates in emissions monitoring systems and to track the release of gases into the atmosphere.

- Food and Beverage Processing: Thermal mass flow meters are used in food and beverage processing to measure the flow rate of gases used in packaging, carbonation, and other processes.

Advantages of Thermal mass flow meter:-

There are several advantages of using thermal mass flow meters for measuring gas flow rates:

- High Accuracy: Thermal mass flow meters provide high accuracy and precision in measuring gas flow rates, making them ideal for applications where precise measurements are required.

- Wide Range of Flow Rates: Thermal mass flow meters can measure a wide range of flow rates, from very low to high, which makes them suitable for a variety of applications.

- Direct Mass Flow Measurement: Thermal mass flow meters measure gas flow rates directly, without the need for additional calculations or measurements.

- Low Pressure Drop: Thermal mass flow meters have a low-pressure drop, which means that they do not significantly affect the flow of gas in the pipeline or duct, making them ideal for applications where the pressure drop needs to be minimized.

- No Moving Parts: Thermal mass flow meters have no moving parts, which means they require minimal maintenance and have a longer lifespan than other types of flow meters.

- Wide Range of Gases: Thermal mass flow meters can measure the flow rates of a wide range of gases, including compressed air, natural gas, and other industrial gases.

Disadvantages of Thermal mass flow meter:-

Although thermal mass flow meters have several advantages, they also have a few disadvantages:

- Limited to Gases: Thermal mass flow meters are designed to measure the flow rate of gases only and cannot be used to measure the flow rate of liquids or slurries.

- Limited Turndown Ratio: Thermal mass flow meters have a limited turndown ratio, which means that they may not be able to accurately measure flow rates at very low or high flow rates outside their specified range.

- Susceptible to Contamination: Thermal mass flow meters can be susceptible to contamination by dust, dirt, or other particles in the gas stream, which can affect the accuracy of the measurements.

- Sensor Fouling: Thermal mass flow meters can experience sensor fouling if the gas being measured contains condensable vapors or particles that can build up on the sensor and affect its accuracy.

- High Cost: Thermal mass flow meters can be more expensive than other types of flow meters, especially if they require a custom installation.

Read Also

- Motor Operated Valve Problems and Troubleshooting

- Difference Between Solenoid Valve and Motorized Valve

- Control Valves Leakage Classifications

- Control Valve Passing Problem after Overhauling Job

- How to Do Maintenance of Control Valve Which is Stuck in Field?

- Zirconia Oxygen Sensor

- TCD | Transcranial Doppler

- How to Solve On-Off Valve Problems?

- Motor Operated Valve Problems and Troubleshooting

- 100 Interview questions with answers on Control valve in simple words for competitive exams