Table of Contents

Actuators play a crucial role in various industries and technological applications. They are mechanical devices that convert energy into motion, enabling machines and systems to perform specific tasks. From controlling valves in industrial processes to powering robotic movements, actuators are widely used across different domains. In this article, we will explore what actuators are, how they work, and the different types available.

1. Introduction

In the world of engineering and automation, actuators serve as the driving force behind the controlled movement of various mechanisms. By converting different forms of energy into mechanical motion, these devices are pivotal in making machines perform desired actions accurately and efficiently. Actuators find applications in diverse fields such as robotics, aerospace, automotive, manufacturing, and more.

2. Understanding Actuators

An actuator is essentially a component or a mechanism responsible for moving or controlling a system or a part of it. It converts an input signal, such as electrical or hydraulic energy, into physical motion. Actuators can provide linear or rotational movement, depending on the application’s requirements. They are designed to perform specific functions, whether it’s opening and closing valves, moving a robotic arm, adjusting control surfaces, or any other desired action.

3. Types of Actuators

There are various types of actuators available, each suitable for specific applications. Let’s explore some of the most common types:

3.1 Electric Actuators

Electric actuators are powered by electricity and are widely used due to their simplicity and ease of control. They utilize electric motors to generate motion, making them suitable for precise positioning and repetitive tasks. Electric actuators find applications in robotics, industrial automation, medical equipment, and more.

Read More About Electric Actuator

Read More About Electric Actuator In Hindi

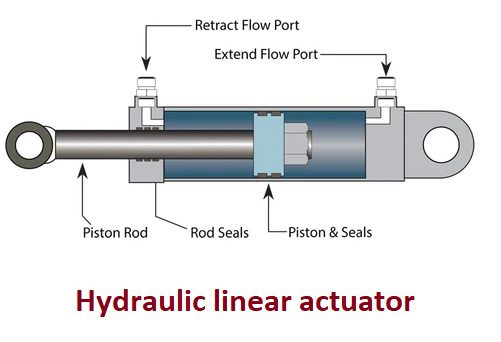

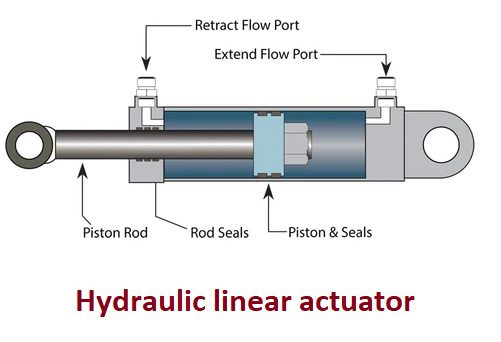

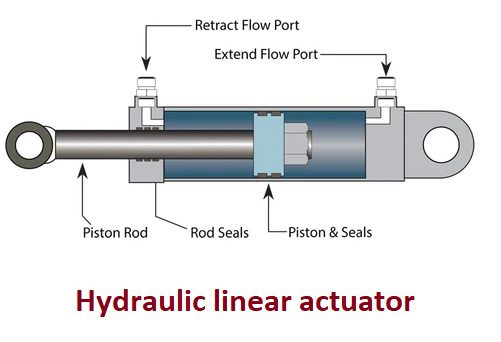

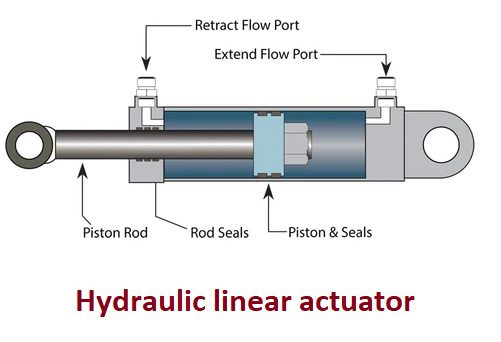

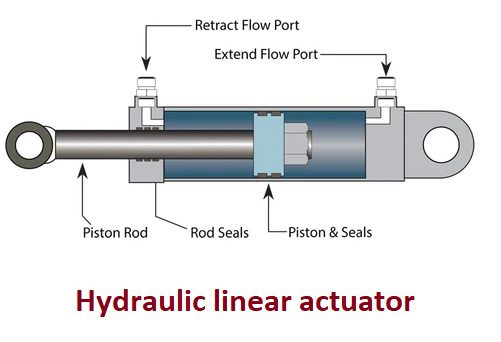

3.2 Hydraulic Actuators

Hydraulic actuators use pressurized fluid to generate motion. They are known for their high force capabilities and are often utilized in heavy machinery, construction equipment, and industrial processes that require substantial power output.

Read More About Hydraulic Actuator

Read More About Hydraulic Actuator in Hindi

3.3 Pneumatic Actuators

Pneumatic actuators use compressed air or gas to produce mechanical motion. They are widely employed in industries where fast and precise movement is required, such as in assembly lines, robotics, and automation systems.

Read More About Pneumatic Actuator

Read More About Pneumatic Actuator in Hindi

3.4 Mechanical Actuators

Mechanical actuators rely on mechanical force, such as a screw or a lever, to produce movement. These actuators are relatively simple in design and find applications in various devices, including mechanical presses, gates, and clamps.

Read More About Mechanical Actuator

Read More About Mechanical Actuator in Hindi

3.5 Electro-Mechanical Actuators

Electro-mechanical actuators combine electrical and mechanical components to achieve motion. They often incorporate an electric motor, gears, and a lead screw arrangement to convert rotary motion into linear motion. These actuators are commonly used in aerospace, automotive, and industrial applications.

3.6 Thermal Actuators

Thermal actuators utilize heat to induce movement. They rely on the expansion or contraction of materials with temperature changes to generate mechanical displacement. Thermal actuators find applications in temperature control systems, valves, and switches.

3.7 Piezoelectric Actuators

Piezoelectric actuators employ piezoelectric materials that change shape when subjected to an electric field. This property allows them to generate precise and fast movements. They are commonly used in nanotechnology, optics, and medical devices.

3.8 Shape Memory Alloy Actuators

Shape memory alloy (SMA) actuators are capable of returning to their original shape after deformation when subjected to temperature changes. They are used in various applications, including robotics, aerospace, and biomedical devices.

3.9 Magnetic Actuators

Magnetic actuators utilize the magnetic field to generate mechanical force. They are often used in relays, solenoids, and magnetic switches due to their fast response time and reliability.

3.10 Electroactive Polymer Actuators

Electroactive polymer (EAP) actuators use polymers that change shape when an electric field is applied. They are known for their flexibility, low weight, and silent operation. EAP actuators find applications in robotics, haptic devices, and artificial muscles.

3.11 Hydraulic-Mechanical Actuators

Hydraulic-mechanical actuators combine hydraulic and mechanical principles to generate motion. They are commonly found in heavy machinery, construction equipment, and aerospace applications.

3.12 Electro-Hydraulic Actuators

Electro-hydraulic actuators utilize electrical energy to control hydraulic systems. They provide precise control and are commonly used in industrial automation, flight simulators, and material testing machines.

3.13 Electro-Pneumatic Actuators

Electro-pneumatic actuators combine electrical and pneumatic systems to achieve motion. They are widely used in industries such as automotive manufacturing, packaging, and material handling.

3.14 Electromagnetic Actuators

Electromagnetic actuators use magnetic fields to produce mechanical force. They are commonly used in applications like linear motors, loudspeakers, and magnetic levitation systems.

3.15 Electrostatic Actuators

Electrostatic actuators rely on the principle of electrostatic attraction and repulsion to generate motion. They are often used in microelectromechanical systems (MEMS), optical devices, and micro-robotics.

4. Factors to Consider When Choosing an Actuator

When selecting an actuator for a specific application, several factors should be taken into consideration:

- Required force and torque

- Speed and acceleration

- Precision and repeatability

- Environmental conditions

- Power source availability

- Cost and maintenance requirements

By carefully evaluating these factors, one can choose the most suitable actuator that meets the application’s needs.

5. Conclusion

Actuators are essential components in the world of automation and engineering. They enable the precise control and movement of various systems, ensuring efficient and reliable operation. With a wide range of actuator types available, choosing the right one depends on the specific application requirements. Whether it’s electric, hydraulic, pneumatic, or other types of actuators, each serves a distinct purpose in driving motion and functionality.

6. FAQs

FAQ 1: How does an actuator work?

Actuators work by converting energy from one form to another to produce mechanical motion. Depending on the type of actuator, this energy can be electrical, hydraulic, pneumatic, or other sources.

FAQ 2: What are some common applications of actuators?

Actuators find applications in various industries, including robotics, manufacturing, aerospace, automotive, and medical equipment. They are used in valve control, robotic movements, machinery operation, and more.

FAQ 3: How do I choose the right actuator for my application?

To choose the right actuator, consider factors such as required force, speed, precision, environmental conditions, power source availability, and cost. Evaluate these factors to match the actuator’s capabilities with the application’s needs.

FAQ 4: Can actuators be controlled remotely?

Yes, many modern actuators can be controlled remotely through the use of sensors, controllers, and communication systems. This allows for automation and remote operation of various mechanisms.

Read Also

- Purpose of 100% and 30% Feed Control Valves in a Power Plant

- Rotork Motor Operated Valve Basic Configuration

- Automated Block Valve (ABV)

- SIS Emergency Block Valves (EBV)

- Control Valve Preventive Maintenance

- ON OFF Valve Preventive Maintenance and Testing Procedure

- Difference Between Linear Actuator and Rotary Actuator

- Solenoid Valve Problems and Solutions

- Quick Exhaust and Air Operated Valves in Instrumentation Circuit