Table of Contents

Non return valves or NRV valve are small, simple, and inexpensive sections whose main function is to allow fluid to run in only one direction. Non return valves are most popular and used within the industry. In different equipment and systems, you’ll definitely find NRVs. But do they look and function the same? No. There are different types of NRVs that not only look different but are used in different circumstances. We’ll introduce 6 of the most popular types of NRVs in this article with more information about their nature and usage.

What are Non Return Valves(NRV valve)?

There are many types of non return valves, but their main function is similar at its core. Non return valves basically allow flow to move in only one direction. As a result, they are also known as one-way valves. NRVs are also considered a type of two-port valve because they have two openings: one opening is for the fluid to exit and the other for the fluid to enter. NRVs usually do not require manual assistance and function automatically. Therefore most NRVs do not have a stem or handle.

Working non-return valve

Non-return valves(NRV valve) use mechanisms to allow the medium through only in the right direction. It has two gates; One inlet and the other outlet. A closing member separates the inlet and outlet that reside in the middle. When the fluid enters the non-return valve through the valve inlet, the pressure of the fluid keeps the closing member open. On the other hand, when the fluid tries to flow in the backward direction from the outlet side to the inlet side, the closing member closes the inlet which stops the flow. Non-return valves operate automatically without the need for control from any external element.

What are the types of non-return valves?

-

Lift Check Valve

Lift check valves are typically used for high pressure service and when there is a high velocity of flow. In these valves, the piston disc is precisely target-hunted by long contact and the thickness of the piston and dashpot walls are approximately equal. Large steam jackets are employed in the pistons and on the exterior of the dashpot. This will prevent exiting due to miscellaneous enlargements. The seat design of a lift check valve can be compared to that of a globe valve. The disc is usually inside a ball or piston type. In thrust fluid service, ball-lift checks are engaged. The top-notch leak-tight feature of these check valves is better than that of swing check valves.

-

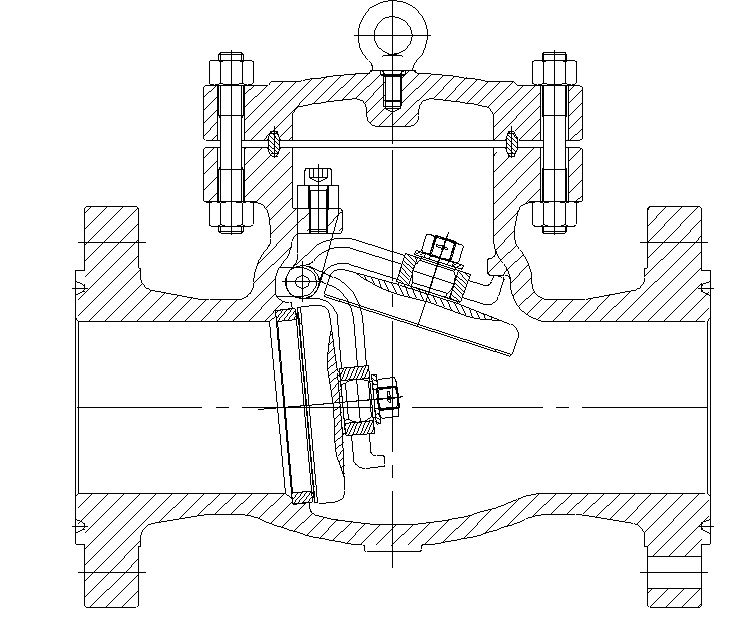

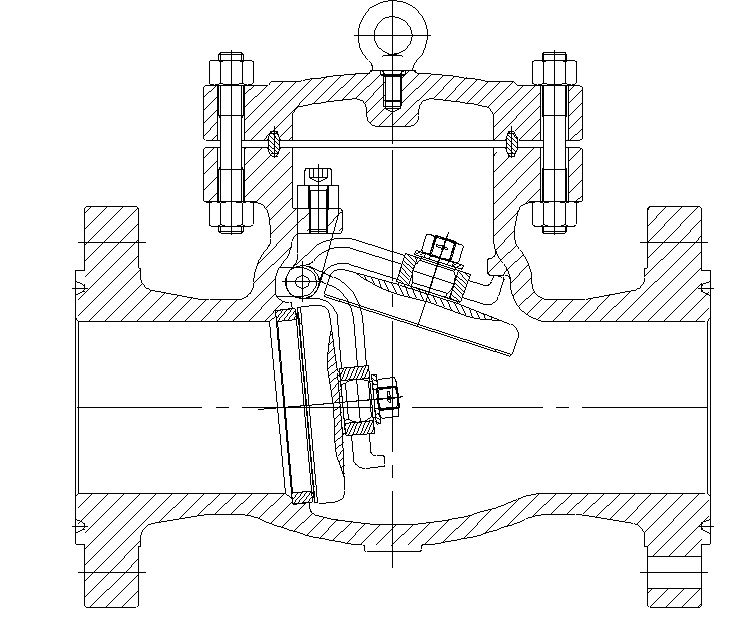

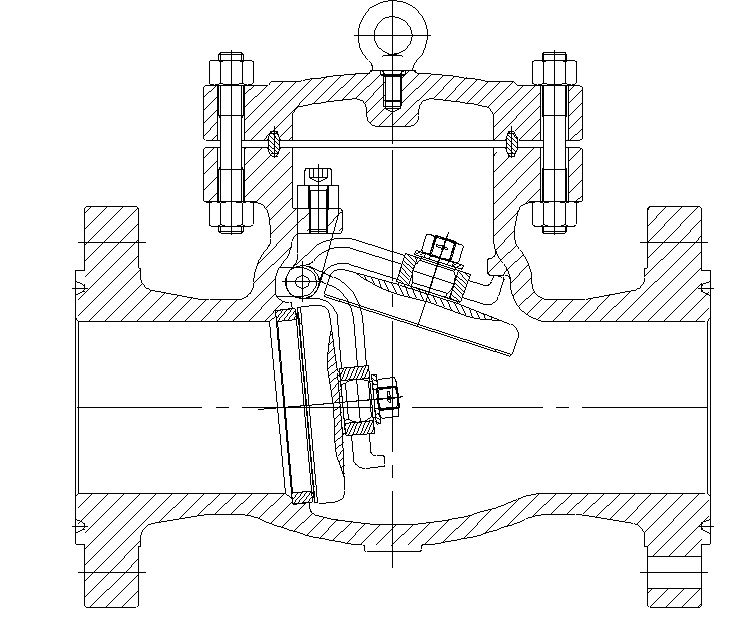

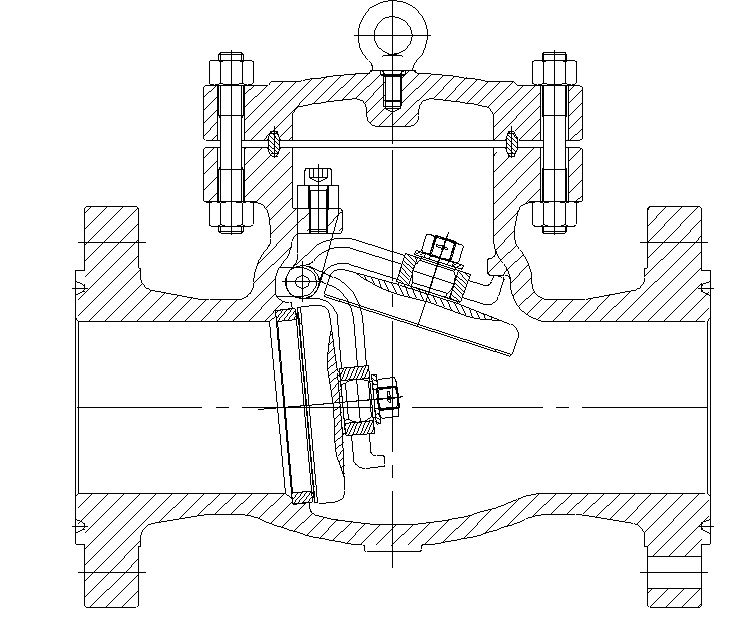

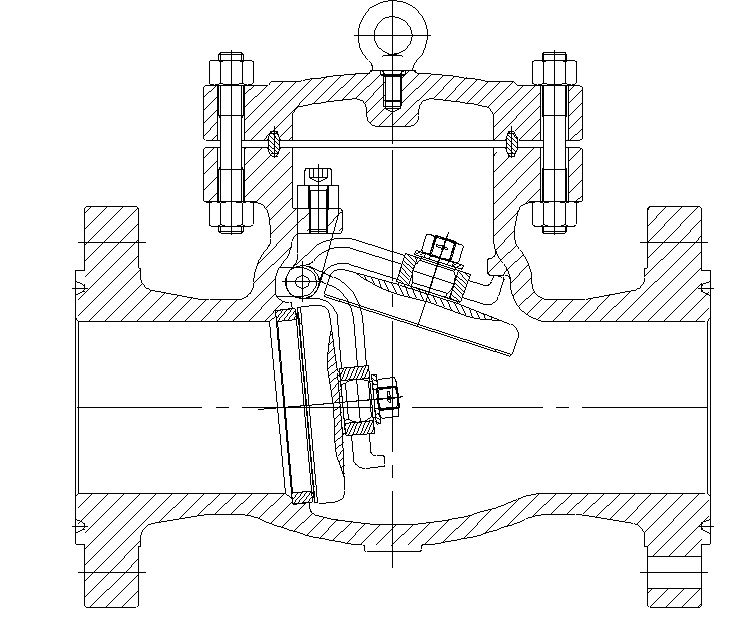

swing check valve

Once the disc in a swing check valve turns into the fully closed or fully open position, it becomes unidirectional. There are many different disc and seat designs that are usable for many situations. Compared to metal-to-metal seating surfaces, soft-seated swing check valves are more leak-tight. In order to achieve high anti-leakage feature, the seats are combined with a metal seat ring and a flexible insert. As you know, the seating angle is the angle between the vertical surface and the seat. This angle can vary from 0 to 45 degrees. The larger the seat angle, the more limited the movement of the disc and the quicker it closes, therefore reducing the loud noise, making them especially quiet in non return valve types.

-

Folding Disc Check Valve

Folding disc check valves are made in factories in a wafer-body pattern. These valves have soft or flanged seats that are commonly used in gas field services and low pressure liquids. Its main feature is a light compact structure. This feature makes this valve extremely popular when convenience and acreage are needed. Folding disc check valve is also known as double-disc or split disc check valve.

-

Tilting Disc Check Valve

There are many drawbacks with swing check valves that have been fixed with the creation of the tilting disc check valve. This valve is specifically designed to be able to open fully. It can also be stable when the flow velocity is low and close quickly when further flow is stopped. The disc of this valve floats within the flow and the fluid moves on its top and bottom surfaces. This dome shaped disc mechanism minimizes the dashpot effect. Among the types of non return valves, these valves are perfect for turbulent, pulsating and high velocity flow. These characteristics result in lengthening of the lift of the valve and cut back flow-induced dynamic mass on the piping system.

-

Stop Check Valve

Stop check valves are used either as isolation (stop) valves which are a type of globe or gate valve or as one-way check valves. Within normal system operation, these valves are employed as daily check valves. However, when required, these valves can be closed by screw-down stems. This stem is not mounted on the valve disc. When the stem is fully screwed in, it can hold the free-floating disc against the valve seat. This process also occurs in globe or gate valves. There are different types of these valves including Y-pattern, angle-pattern, T-pattern and inclined pattern. Swing-and-piston lift-disc style check valves are typically operated to prevent check valves.

-

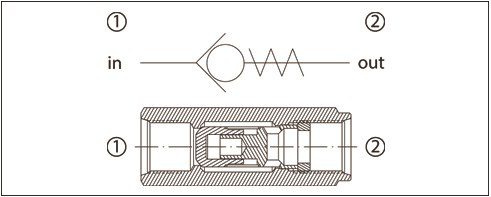

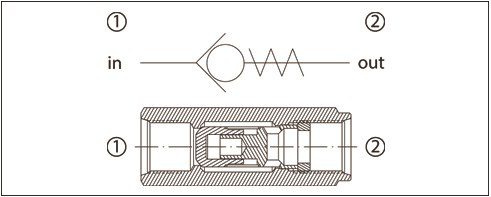

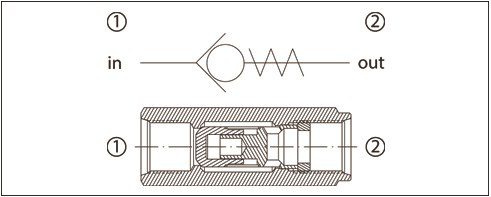

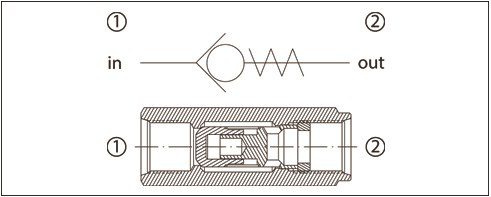

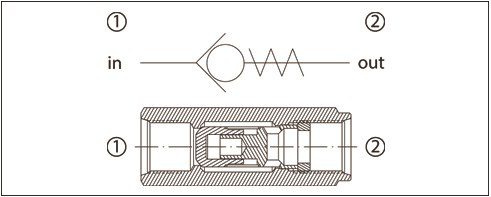

Vertical or In-line Check Valve

Vertical or in-line check valves are types of non return valves(NRV valve) that also come in 2 arrangements: In-line ball check valves are used in both horizontal and vertical lines. When used in horizontal lines, fully guided disc inline check valves must have spring-assisted closure. But when used in vertical lines, spring-assisted closure may or may not be supplied. Not only is the spring-assisted closure effective at rapidly closing the valve; It also prevents flow reversal and hence reduces loud noise. These valves can be used in pulsating flows such as the discharge line of a reciprocating compressor. Their compact size makes them popular for small areas.

Applications of Non-Return Valves

Pump Discharge: A non-return valve known as a check valve is always installed on the pump discharge piping to prevent backflow of fluid.

Transportation Fluid Systems: Transportation fluid systems use non-return valves in their pipelines to avoid backward movement of the fluid.

Nuclear industry: nitrogen feed system, dump line.

industrial sampling system.

Fluid injection systems of aircraft, spacecraft.

laboratory purification system.

Mixing Chamber: A non-return valve is installed in each line to avoid gas mixing with the original source.

Domestic applications such as sprinkler systems, home heating systems, inflatable mattresses and boats, drip irrigation systems, rainwater harvesting systems, hydraulic jacks, etc.

Non-Return Valve Symbol

Selection Non-Return Valve(NRV valve)

Selecting the proper type of NRV helps in smooth, trouble-free, low-maintenance, long-term operation. The selection of an NRV is influenced by various parameters like:

- Type of fluid to be carried.

- Location of the non-return valve

- Pressure and temperature of the flowing fluid.

- Hydraulic characteristics like minimum and maximum flow rates

- Closing time (Slow, normal, or fast-acting)

- Installation type; Vertical or Horizontal

- Cost

Read Also