Table of Contents

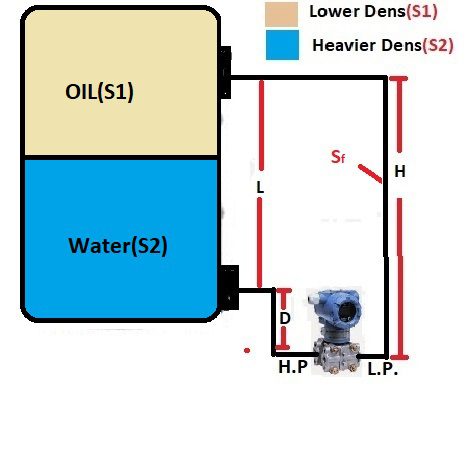

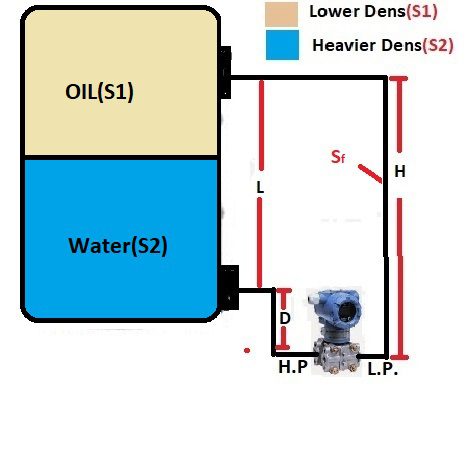

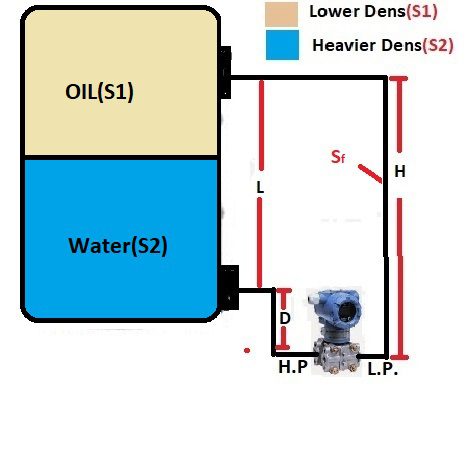

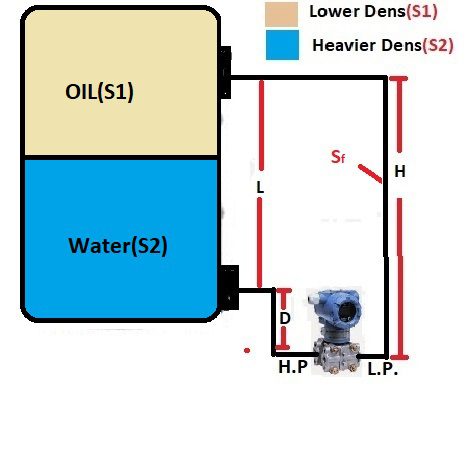

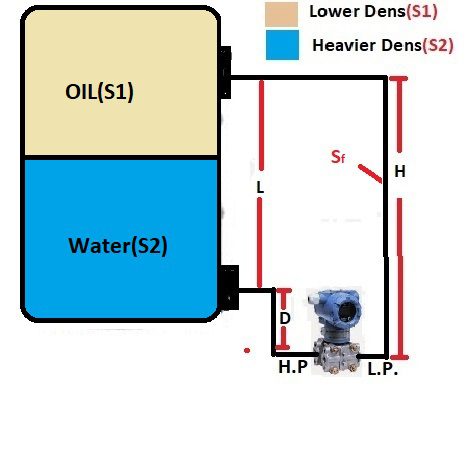

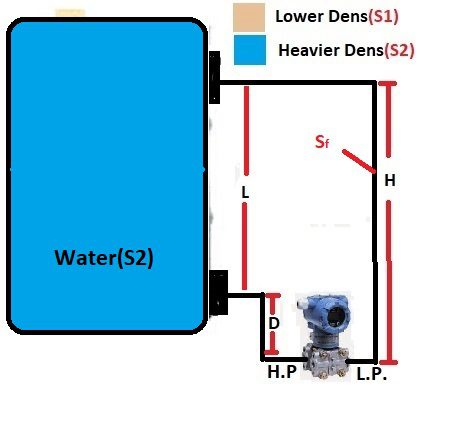

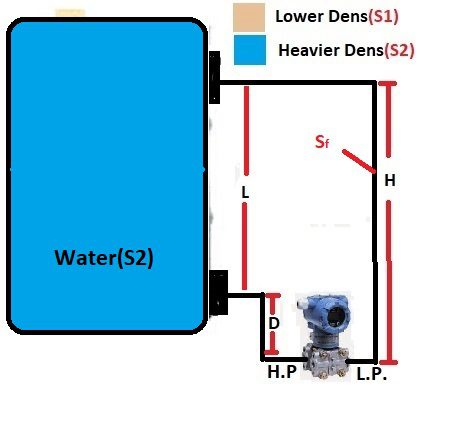

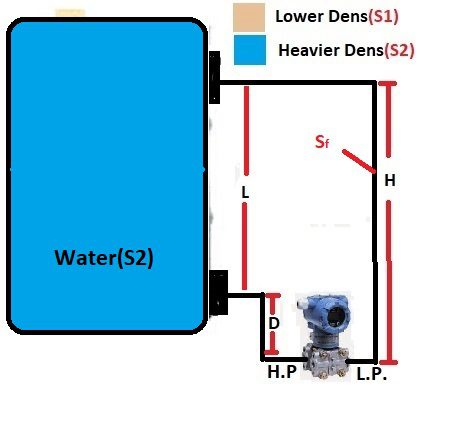

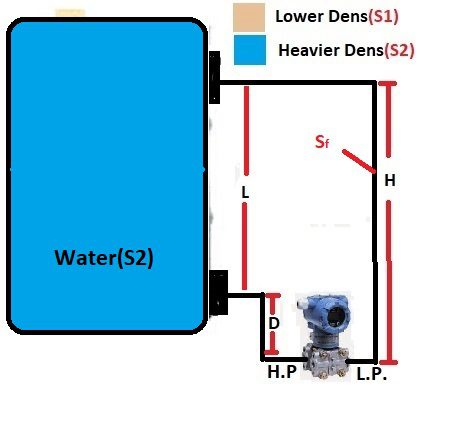

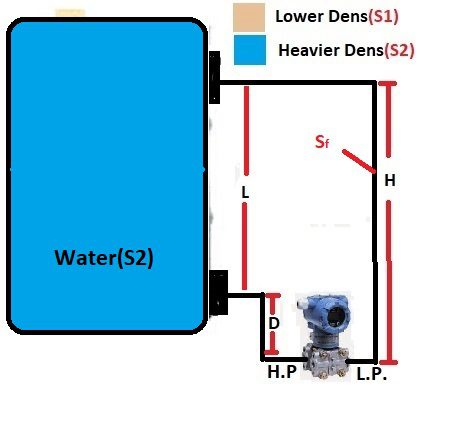

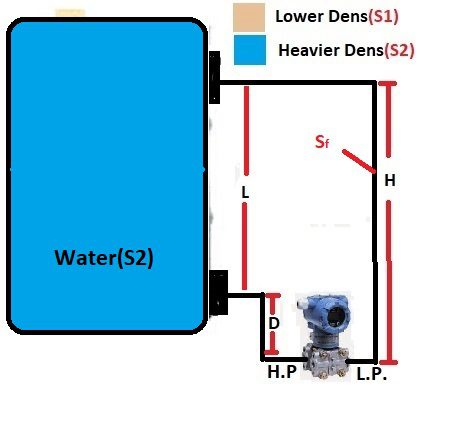

Interface level measurement is used to monitor the level of two liquids with different specific gravity values. When two different liquids are contained within the same tank, but are unable to mix with each other, an emulsion layer forms and creates a barrier between the two liquids. When two insoluble materials mix, the liquid with the heavier molecules will sink to the bottom while the lighter ones will stay on top, oil and water is perfect example of this.

What is a Level Interface?

The dissimilar density, or specific gravity, of two liquids contained in the same vessel or tank, means the higher density liquid will sink to the bottom allowing the lower density liquid to float above. Where these two liquids meet is called the Interface.

Interface Level Measuring Techniques

There are many techniques employed to measure level interface and depending on the fluids being measured, some work better than others. First here we will discuss about Interface level measurement by using DP transmitter.

To determine the calibrated range for the transmitter, given point should be remember-

- Overall level should be equal to or higher than the upper (low pressure) tap.

- This can be measure with either a remote seal system or a wet leg. The reference level must have a constant height and density. The calculation is modified slightly for wet leg systems when the density of the high and low pressure wet legs differ.

- At the lower calibrated value, 4 mA point, the tank is filled with the lighter fluid(S1).

- At the upper calibrated value, 20 mA point, the tank is filled with the heavier fluid().

DP transmitter basically measure difference of pressure applied on H.P. & L.P tapping and provides 4 to 20 mA output in the calibrated range.

Calculation for LRV (4mA):-

Before calculating LRV (lower range value), we have to keep in mind that the tank is never empty at the interface level. Rather the material is filled with material of lower density.

DP at Transmitter = Pr. At H.P. Side – Pr. At L.P. Side

Pressure on HP side = (S1*L) + (Sf*D)

Pressure on LP side = Sf*H

DP = HP – LP

LRV = DP = {(S1*L) + (Sf*D)} – (Sf*H)

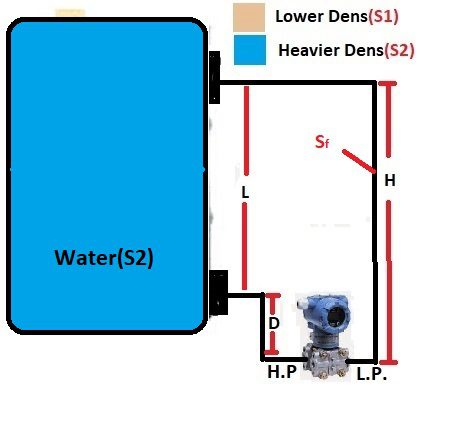

Calculation for URV (20mA):-

Before calculating URV (lower range value), we have to keep in mind that the tank is always fill with two different density material in the interface level. To calculate URV we should assume that tank is filled with heavier density material.

Than

DP at Transmitter = Pr. At H.P. Side – pr. At L.P. Side

Pressure on HP side = (S2*L) + (Sf*D)

Pressure on LP side = Sf*H

DP = HP – LP

URV = {(S2*L) + (Sf*D)} – (Sf*H)

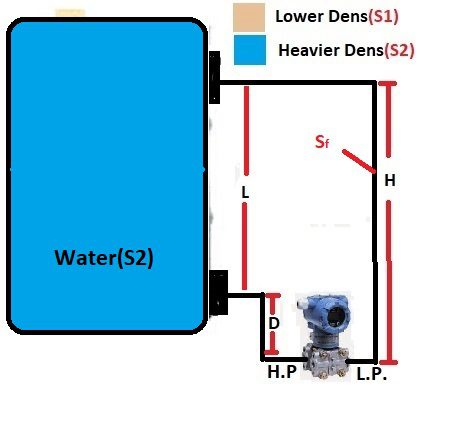

Example: – A close vessel filled with two different density materials that is LPG (0.5 g/cm³) and Water (1 g/cm3), A remote seal DP transmitter installed at the height of LP tapping with 1.1065 g/cm3density material filled in capillary. The height of HP and LP Tapping is 1000 mm.Than what is the Range of Transmitter?

Given :-

S1 = 0.5 g/cm3

S2 = 1 g/cm3

Sf = 1.1065 g/cm3

L=1000

D=0

H= L+D = 1000

LRV = DP = {(S1*L) + (Sf*D)} – (Sf*H)

LRV = {(0.5*1000)+(1.1065*0)}-(1.1065*1000)

= {500+0}-1106.5

LRV = -606.5 mmH2O

URV = {(S2*L) + (Sf*D)} – (Sf*H)

URV = {(1*1000)+(1.1065*0)}-(1.1065*1000)

= {1000+0}-1106.5

URV = – 106.5

The above calculation is given in the interface level measurement to measure the level of heavier density liquid. Mostly the level of heavier density liquid is measured at the interface level.

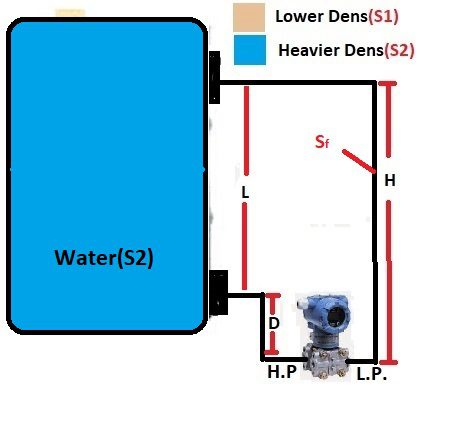

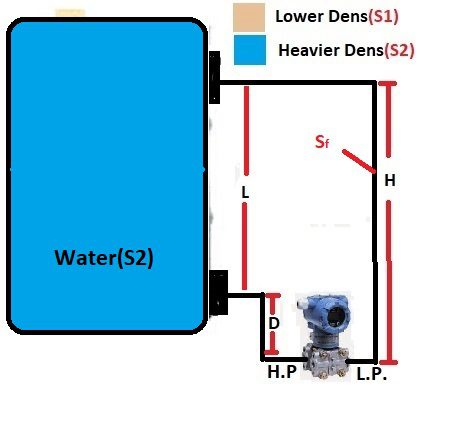

But if we have to measure the level of liquid of lower density then what will be the calculation? Let’s Calculate-

Calculation for LRV (4mA):-

In measuring the level of lower density material, LRV will occur when the heavier density material is filled in the tank.

Pressure on HP side = (S2*L) + (Sf*D)

Pressure on LP side = Sf*H

DP = HP – LP

LRV = {(S2*L) + (Sf*D)} – (Sf*H)

Calculation for URV (4mA):-

The URV in measuring the level of lower density material will be when the lower density material is filled in the tank

Pressure on HP side = (S1*L) + (Sf*D)

Pressure on LP side = Sf*H

DP = HP – LP

URV = DP = {(S1*L) + (Sf*D)} – (Sf*H)

Read Next:-