Table of Contents

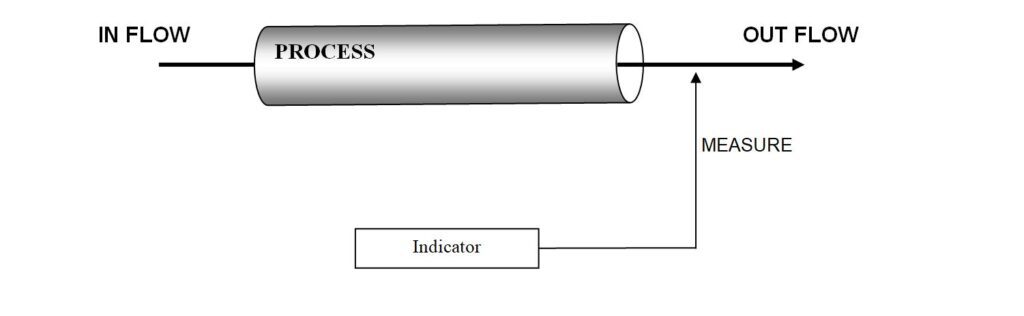

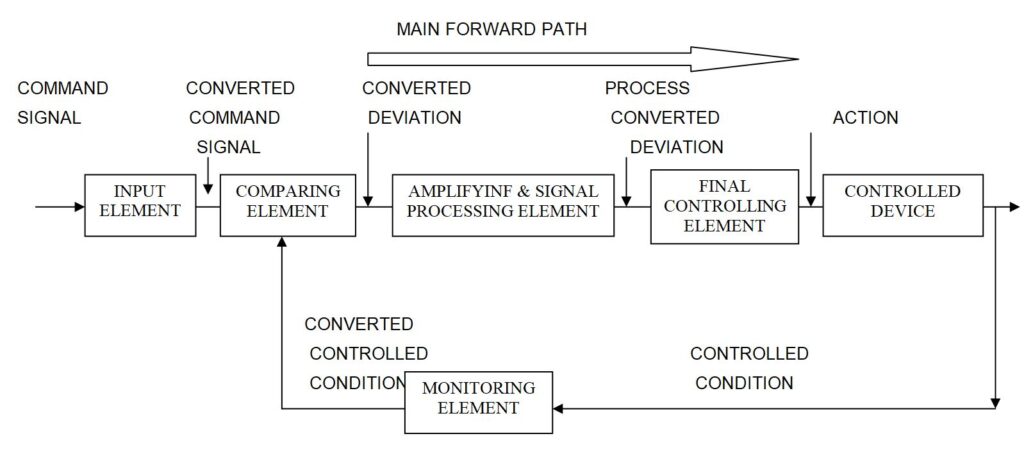

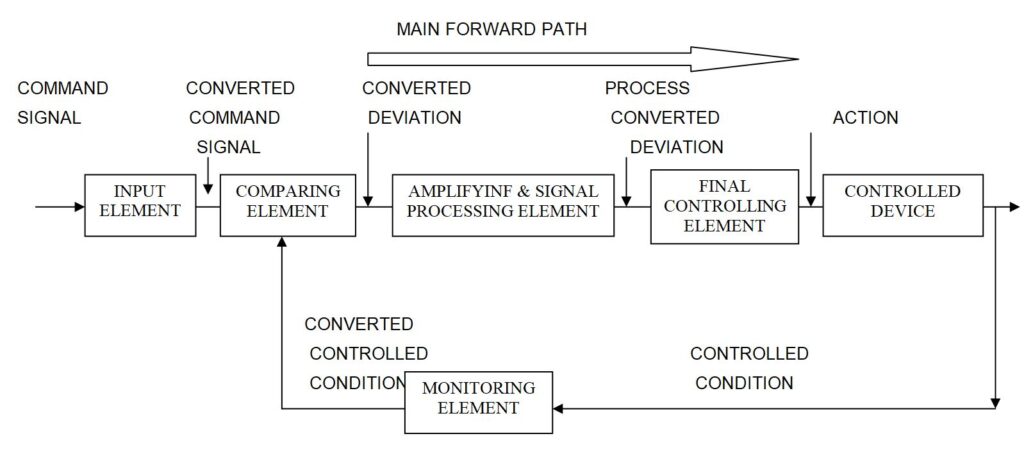

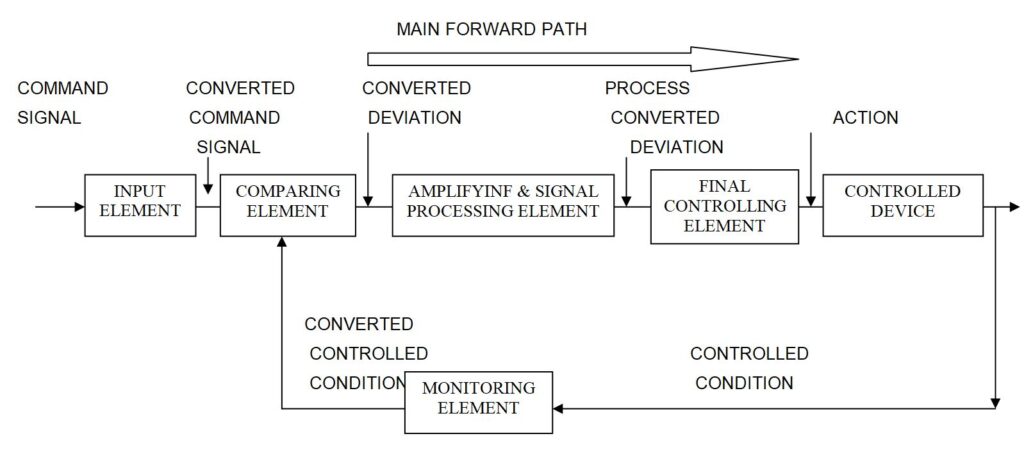

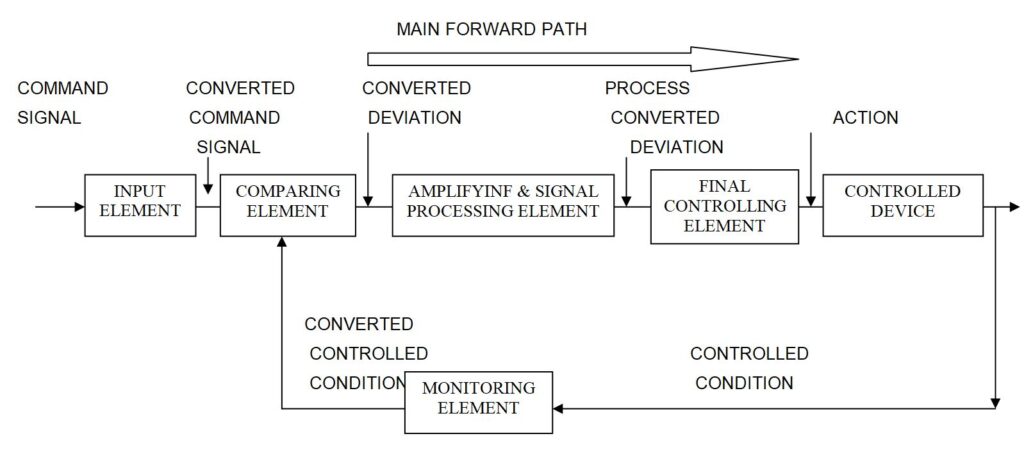

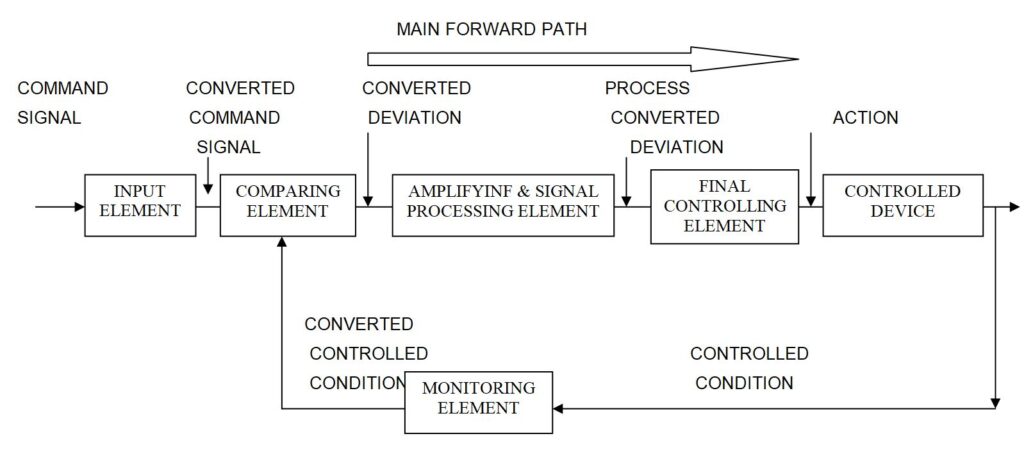

Necessarily, it follows that when we think of a control system, we have to associate with it a standard or set value of a variable. A method of measuring the variable as it goes on changing, on agency to compare the measured value with the set point value and take corrective action to bring the measured value to the set point whenever a deviation takes place. We have now mentioned all the rudimentary aspects of a control system. All these aspects connected together as in the system from , what is known as control loop. The figure includes these various elements and the way they are connected together. In short, a control system is an assemblage of control apparatus co-ordinated to execute a planned set of control function. Reduced to a simple diagrammatic form, an automatic control system is shown in fig-

Open Loop Control System

Suppose you are going under the hot water shower for a bath. You do not just walk under the shower, which is turned on. You first put out your hand so that your fingers come into contact with the water, feel the temperature, decide if it is right for you, turn the hot water or cold water knob to adjust the temperature of the water as necessary. Feel the temperature again, perhaps repeat the whole series of operation, and get under the shower only when the temperature is right for you. In short, you have the control system here to regulate the temperature of the water as necessary for you. But flowing water and its adjustment knobs form one group, and you as the agent making the adjustment stand outside the group. This type of control system will be called an “Open Loop System”. In this, the controller has no place within the control system. But stays separately outside.

In other words, open loop: A system in which no comparison is made between the actual value and the desired value of variable. The figure illustrates the open loop system.

Closed Loop Control System

In a closed loop system, the actual output (go) is measured, compared to the set value of output (gI) and then some condition of the process is adjusted to reduce any difference to a minimum. These are two sub-division of closed loop control, they are manual closed loop and automatic closed loop.

-

Manual Closed Loop:

Where the adjustment is carried out manually the man himself acts as a comparator. Feedback of information to the controller about the controlled condition (go) occurs only when the man makes an adjustment.

-

Local Manual Control:

Both man and the controlling unit are near the process.

-

Remote Manual Control:

In some processes, conditions are such that the process operator has to work at a distance from the process and the controlling unit has to be moved to a position remote from the process.

Automatic Closed Loop:

The manual part of the loop is replaced by a comparing element which gives an output signal representing the difference between the set value of the controlled condition (gI) and the actual value of the controlled condition (go).It is the difference signal which adjusts some condition of the process (correcting condition) to reduce the difference between gI and go to a minimum. As with the manual closed loop systems other process conditions are monitored. Under certain hazardous conditions, some of these monitors (e.g. alarms) may demand shut down of the process which can be done automatically. In short, a Closed loop system is a Combination of control units in which process variable is measured and compared with the desired value (or set point). If the measured value ,a corrective signal is sent to the final control element to bring the controlled variable to the proper value.

-

Automatic Control Requirements

For all processes the instrumentation and the instrumentation and control must fulfill the following functions:

- To vary the controlled condition in accordance with the command signal.

- To correct for any disturbances which will effect the controlled condition.

Any control system may be simply considered in block diagram form. Each block may contain a certain descriptive name (for a loop flow chart ) or an algebraic expression representing its individual output to its input relationship (called the transfer function). Illustration in fig. (C)&(D).

Considering the earlier example in open loop, on the other hand, if the relation of the temperature of a temperature bath is rendered automatic and you have just to turn a knob to make the temperature remains at a particular point; you can get the temperature of water automatically adjusted to any set value. This system would be a “closed loop” control system and can actually assure better regulation. The difference between this system and example of the shower, considered earlier, is that the adjustment for the temperature required is not made separately in several steps, but it is made on a continuous basis by continuous measurement and corrective action as needed.

Read Also

DCS System | Distributed control system | DCS