Table of Contents

Armoured cable consists of a metal layer of strips or threads that protects the conductors from external forces. The external weakening forces for cables are rodents and accidental impact. This prevents any internal disturbances from releasing dangerous energy levels out into the atmosphere.

Armoured cable insulated with non-flame spreading thermoplastic compounds with low emission of smoke and toxic gases, covered with metallic armor.

Installation of Armoured cable is fast and economical. When we use Armoured cable there is no need for rigid conduit pipe like threading, bending, forming supports.

It also avoids waste as Armoured cables are available in continuous rolls of convenient lengths. The armor provides ultimate protection against electrostatic, magnetic and common mode.

What is Armoured cable?

Armoured cable has an extra protective layer to keep it away from unwanted cuts or damage. Armor made of aluminum wires under the sheath to protect the conductors, and insulating layers.

Why is Armored cable used?

For outdoor installation or direct burial applications, mechanical protection of power cables is required. Aluminum wire armor (AWA) and steel wire armor (SWA) provide mechanical protection. Armoured wire has a high tensile load.

The structure of the armor guarantees maximum resistance to crushing, cutting and wear.

Classification of Armoured Cables

We can classify Armoured cables into steel wire, steel tape, aluminum wire and aluminum alloy.

- Steel Wire Armoured Cable (SWA)

- Steel Tape Armoured Cable (STA)

- aluminum wire Armoured cable (AWA)

- braided wire armor cable

Now, we will discuss the types of Armoured cables in detail.

Steel Wire Armor Cable (SWA)

Steel wire Armored cable consists of a strong steel wire conductor assembled with a layer of insulation.

Steel Armored cable (SWA) is the most common type of Armoured cable in electrical power distribution. This is a heavy duty electrical power cable suitable for mains supply. We use this type of cable in electrical installations of 11 kV and 33 kV underground and in cable ducts.

The main purpose of shielded layer steel wire Armoured cable is to improve the tensile strength and compressive strength. It also provides mechanical protection. In addition, it also prolongs the service life and improves the cable’s anti-interference through shielding protection.

Blue Sheathed Steel Wire Armoured (SWA) cables are best suited for instrumentation applications

Steel Tape Armor Cable (STA)

The steel tape and wire armor layers have high permeability and excellent magnetic shielding effect and resist low-frequency interference. The use of steel tape armouring is a popular method of protecting fiber optic cables.

Aluminum Armoured Cable (AWA)

Aluminum wire Armoured cables provide protection from mechanical stress, making Armoured cables suitable for direct burial and for outdoor or underground use.

When current flows through a cable, it produces a magnetic field. The magnetic field induces an electric current (eddy currents) in the steel armature, which can cause overheating in AC systems. Aluminum is a non-magnetic material, non-magnetic aluminum reinforcement prevents this.

Braid wire armor

Braided armor cable consists of many fine copper wires that are intertwined in a tightly meshed tubular structure. It wraps around a conductor. Braided armor cables suppress magnetic fields, and reduce electromagnetic interference between adjacent cables.

Copper braided cables are typically used in environments that transmit high-speed signals that are also susceptible to mechanical damage.

Difference between Steel Wire Armoured (SWA) Cable and Steel Tape Armoured Cable (STA)?

We use Steel Tape Armoured Cable (STA) for direct buried cable or pipe laying, common ground, tunnel etc. STA cables are less expensive than SWA cables.

Steel wire Armoured (SWA) cable can withstand normal longitudinal tension, so it is suitable for short distance aerial laying or vertical or vertical laying.

Because SWA Armoured cables are more difficult to produce, the cost is higher. In general, it is according to the different use methods of the environment and the choice of different shielded SWA cables.

SWA cables are suitable for network cable, Armoured cable, power cable or leaflet Armoured cable.

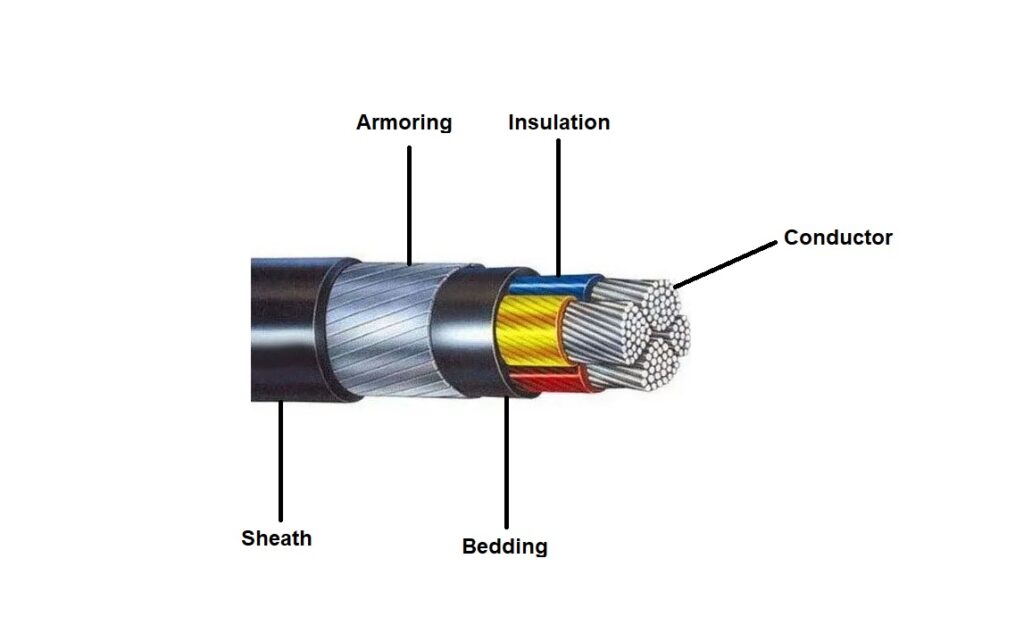

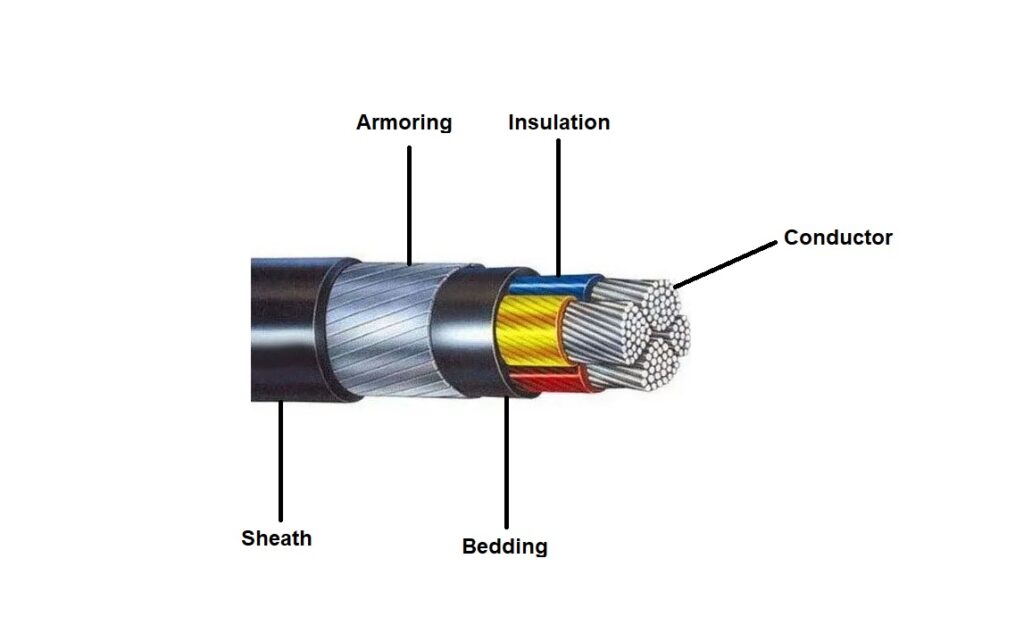

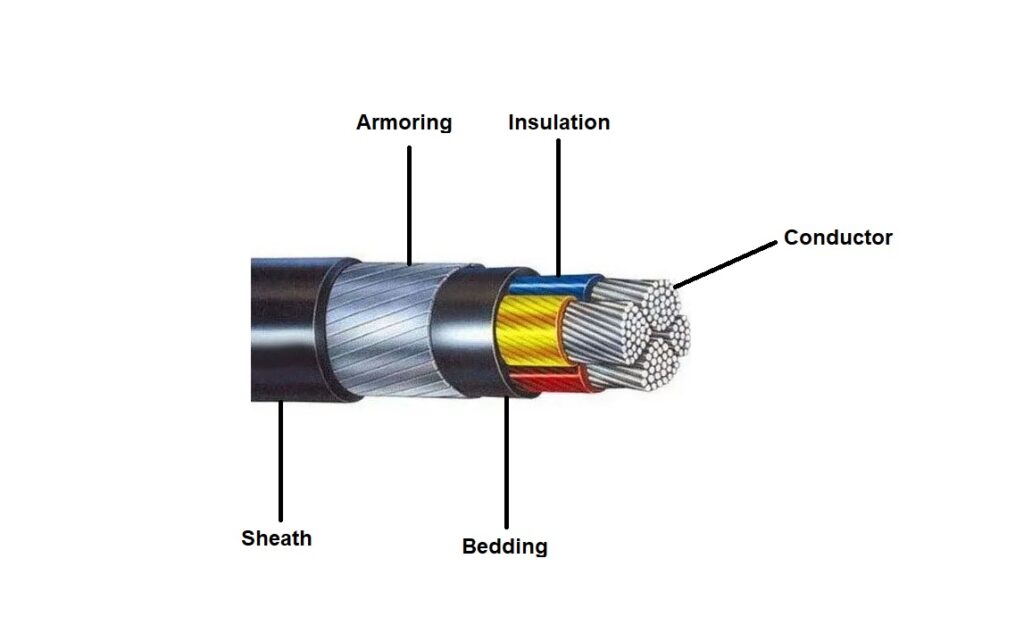

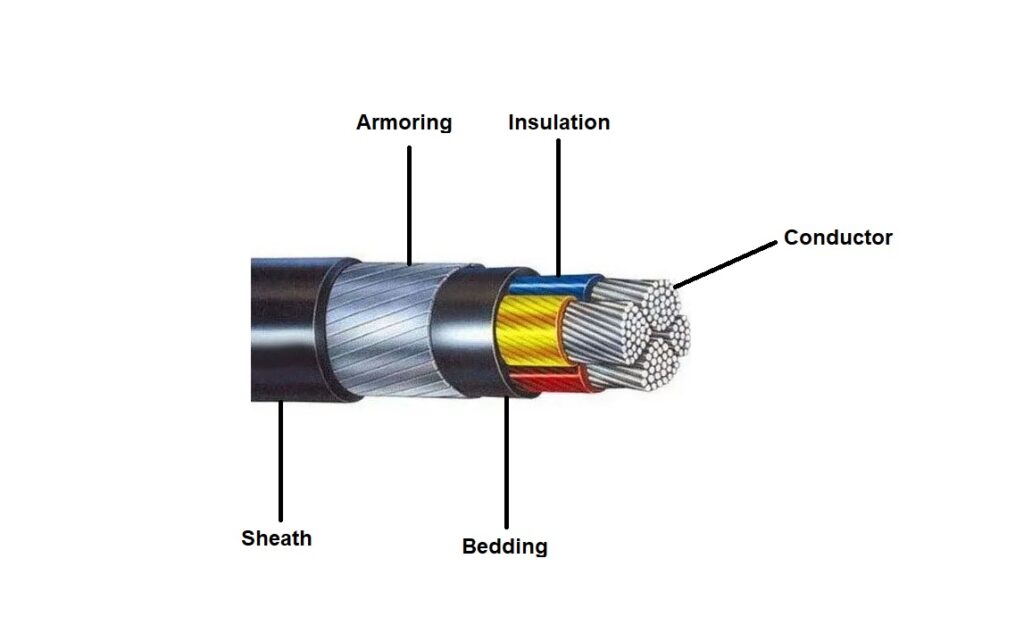

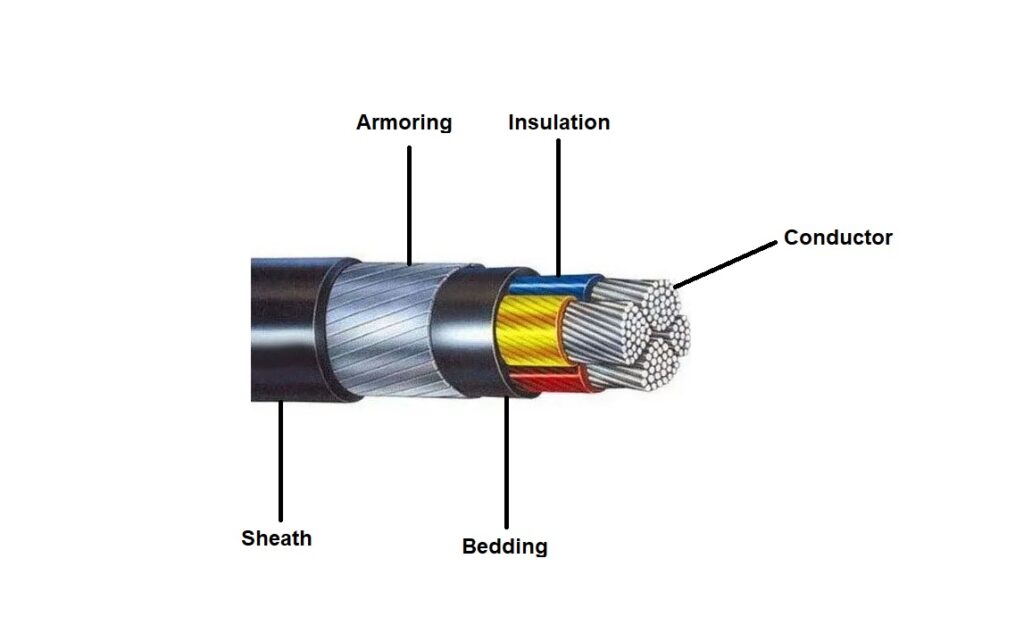

Construction of Armored cable

Conductor

It is the material through which the current flows. Conductors carry electric current from one place to another. Actually, the conductor is the inner part of the cable.

Copper has higher conductivity than aluminum. However, both copper and aluminum are the best choices for an electric conductor.

Insulation

Insulation of any of the following compounds: PVC, PVC+Nylon, Low Density Polyethene, XLP depending on the cable being used.

Cross-linked polyethylene (XLPE) finds its applications in various power cable systems as it has Water resistant and has excellent electrical properties. The conductive parts of the cable must not come into contact with other conductors or metal parts. Cable insulation provides separation between the conductive and non-conductive parts of the cable.

Bedding

Protects the bed sheath from mechanical damage. The bedding forms a protective barrier between the inner and outer layers of the cables.

Shield

Steel wire armor provides mechanical protection to the cable. This means that the Armoured cable can withstand higher stresses. It is also suitable for underground installations. The shield is normally grounded, and may sometimes be used as a protective circuit conductor (“ground wire”) for cable-supplied equipment.

Sheath

The sheath provides good flexibility and holds all cable components together. The sheath protects the cable from UV, water ingress and varying soil compositions.

This provides additional protection from external stresses. Other sheath materials are polyethylene (PE), low smoke halogen free (LSHF), PTFE, rubber and silicone to mention but a few.

Read Also

- Instrumentation Cable | Types and Application

- Cable Trays | Cable tray types

- Cable gland | Cable gland type

- Junction box | electrical junction box