Table of Contents

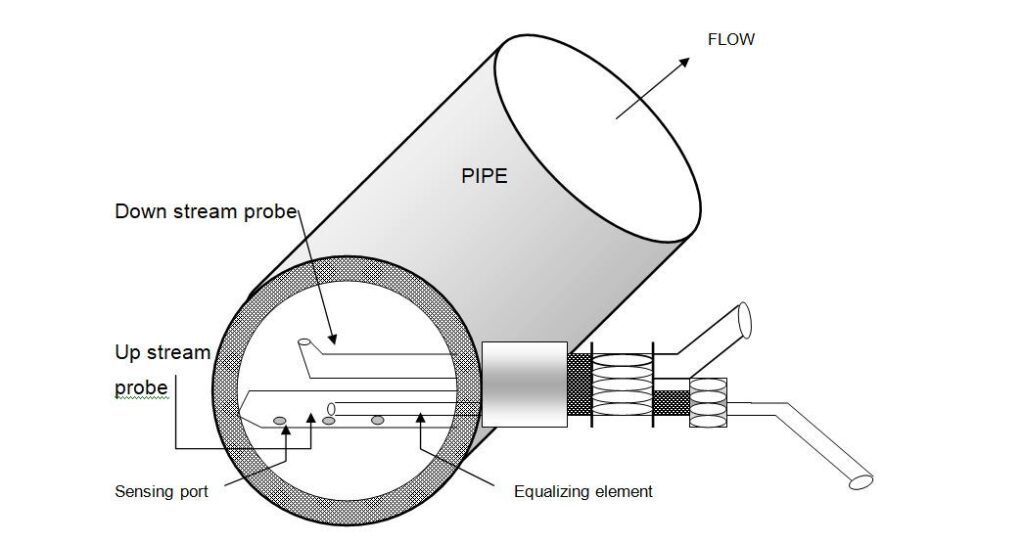

Annubar flowmeter is often called the average pitot. They are used to measure the flow of gas, steam or liquid fluid. An annuity flow meter has several pressure tapes to measure the flow average.Annubar is a simple; unique designed based up on the principles of the fundamental of Bernoulli Flow equation. It consists of two probes inserted into the line in much the same manner as a pitot tube, with one probe facing the flow to sense the velocity pressure, and 2nd probe behind the 1st with its opening facing down stream sensing the static pressure. The probe, which faces up stream, has four sensing ports, each one representing an annular segment of the line. An equalizing line inserted into the plenum of the up stream probe senses the average of the four pressure representing the four line segment, thus providing an average pressure for the entire body of following material. The primary device, with accuracies varying from approximately +/- 0.5 to +/- 1.5 over a wide range of pipe sizes, has received good acceptance in a short period of time. Available for pipe sizes from ½ to 150 inches.

How Annubar Flowmeter works

An annular flowmeter measures the flow of fluid through a differential pressure buildup. It is first inserted into the fluid and then the side with the pressure tape is directed towards the flowing fluid. Pressure tapes measure the total pressure of a flowing fluid which includes both static and dynamic pressures. An anubar flowmeter has single or multiple taps on the other side of the fluid to measure the pressure flowing through the flowmeter.

The difference in pressure between the flowing fluid and the downstream current determines the velocity. This together with the cross-sectional area of the pipe makes it possible to determine the flow of the fluid.

The difference in pressure is determined and converted into flow rate using another device which is a differential pressure transmitter. The main principle guiding the working of an anubar flowmeter is Bernoulli’s equation.

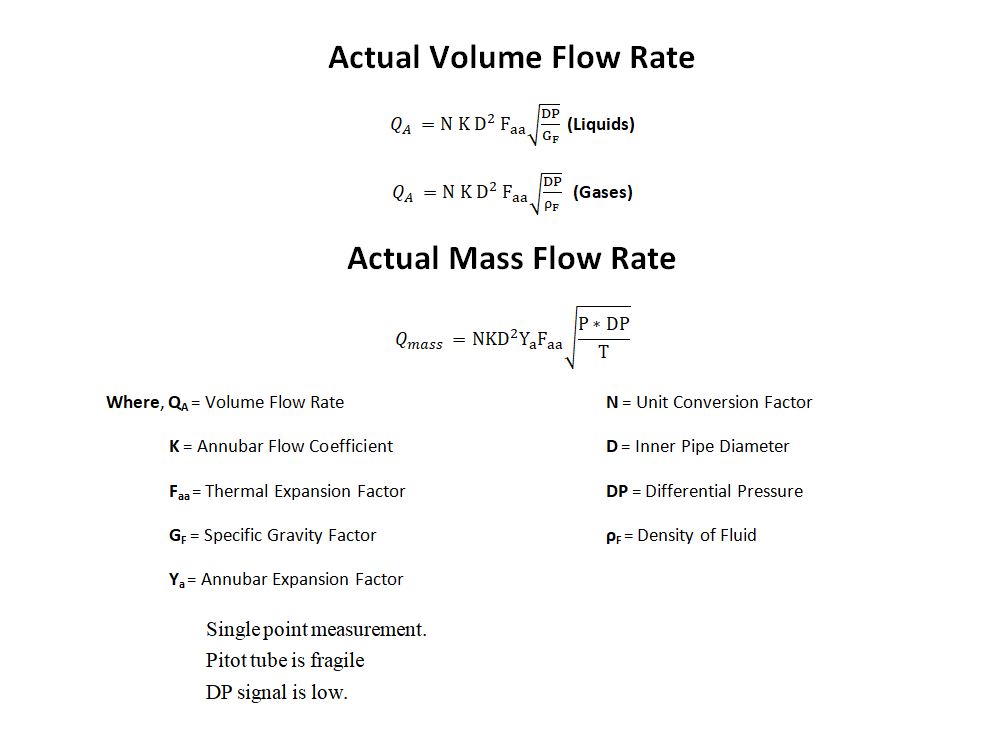

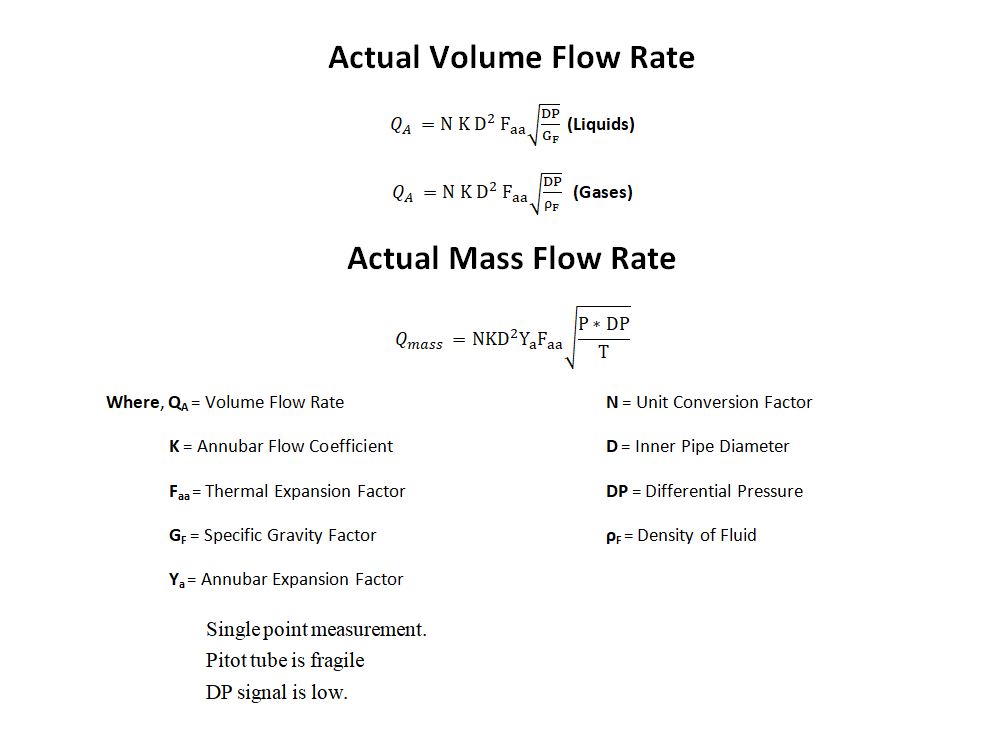

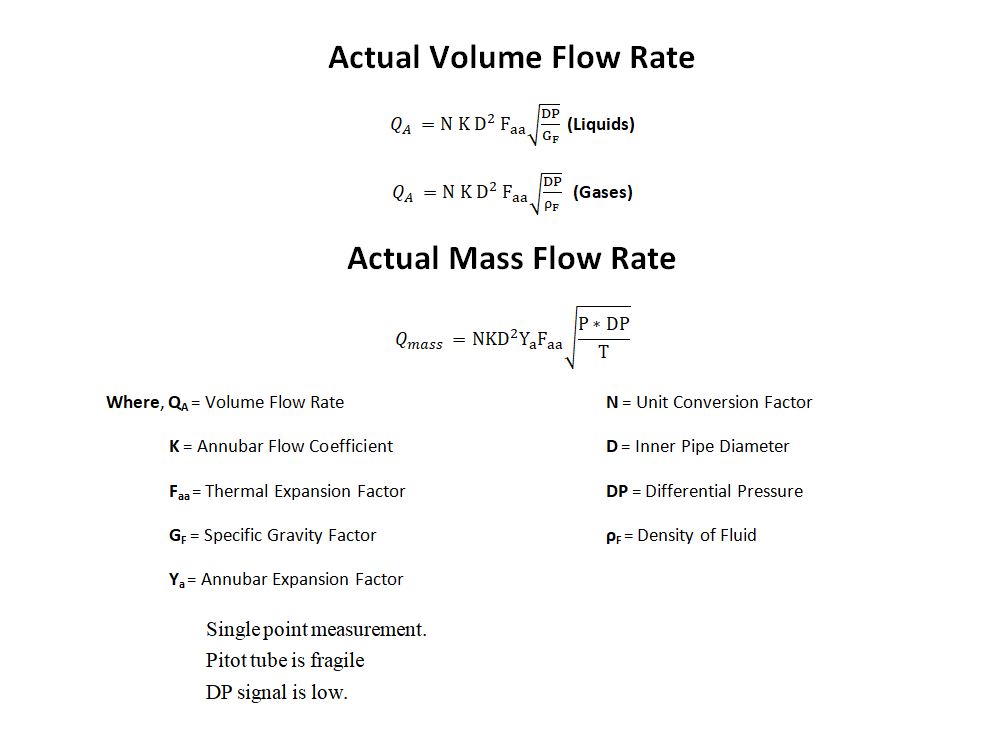

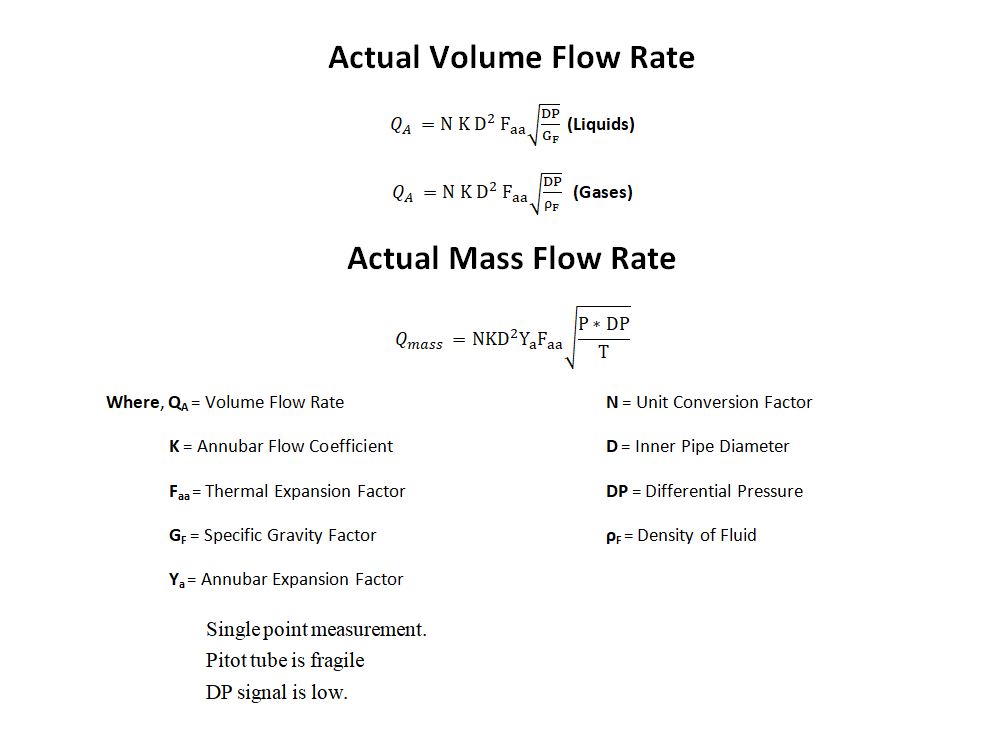

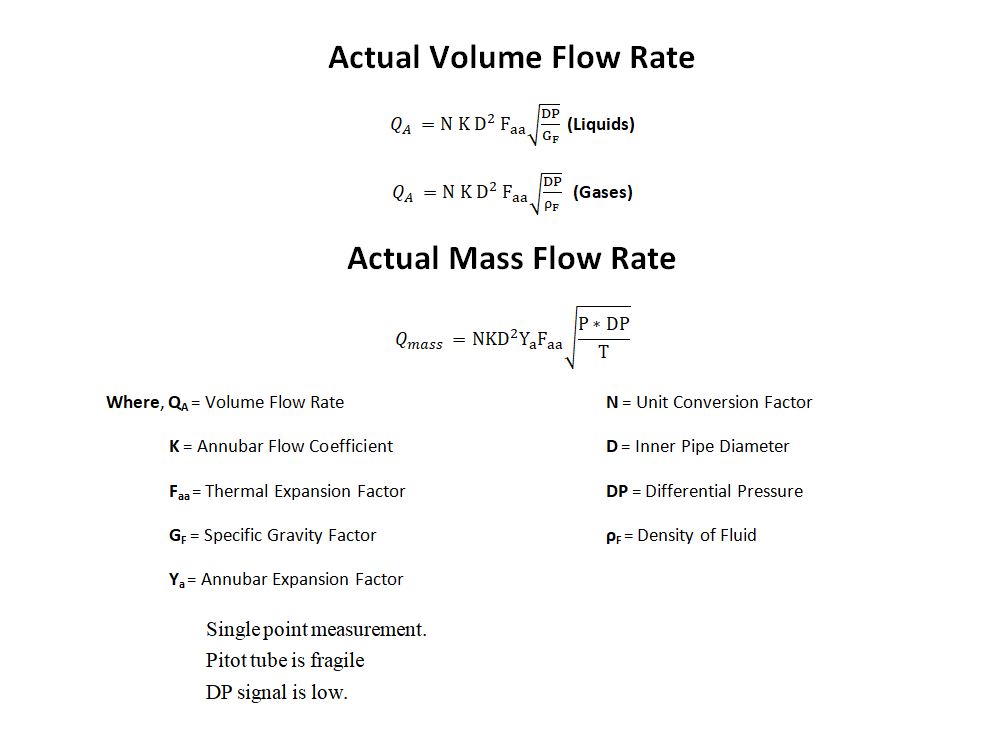

Flow Calculation

The average pitot tube is inserted across the pipe as shown below. On one side of the bar are pressure taps facing the flowing fluid which are coupled to an “average” chamber that measures the total (i.e. static + dynamic) pressure of the fluid.

There may be a single port or multiple tapping ports on the opposite side of the bar to measure low static pressure in the downstream area.

The difference between the total and static pressures is effectively a measure of the fluid velocity head, which together with the pipe area enables the volumetric flow to be determined.

Annubar primary flow element is a device used to measure the flow of liquid, gas or steam fluid that flows through a pipe. This enables flow measurement, according to Bernoulli’s theorem, by creating a differential pressure (DP) that is proportional to the square of the velocity of the fluid in the pipe. This DP is measured and converted into flow rate using a secondary device, such as a DP pressure transmitter.

Flow is related to DP through the following relation.

Q = flow rate

K = Annubar flow coefficient

Δp = differential pressure

Annubar produces a DP by causing a blockage in the pipe and acting as a barrier to fluid. The velocity of the fluid decreases and stops as it reaches the front surface of the Annubar sensor, creating impact/high pressure. Annubar senses impact pressure using DP transmitter.

As the fluid continues to surround the annubar sensor, it creates a lower velocity profile on the rear side of the sensor, creating a lower/suction pressure on the underside of the annubar. Individual ports located on the back of the Annubar sensor measure this low pressure. Working on the same principle as high pressure, an average low pressure is maintained in a low pressure chamber that connects directly to the transmitter for measurement.

The resulting differential pressure effect is the difference between the (high) pressure reading and the suction (low) pressure reading as seen below.

DP = Ph – PL

Where:

Ph = high pressure

PL = low pressure

The measured DP is used to calculate the flow rate.

Technical Parameters

| Fluids | Gas/Steam | Liquid |

| Accuracy | ± 1.5% | ± 1.0% |

| Repeatability | 0.3% | 0.2% |

| Pipeline size | DN80~DN2000 | |

| Ratio Range | ≥10:1 | |

| Operation Pressure | ≤42 Mpa | |

| Fluids Temperature | ≤ 800 ℃ | |

| Straight Pipelines | Upstream 7-24D,downstream 3-4D | |

Annubar Flow Meter Application

- Annubar flowmeters can be used in various applications such as measuring the flow rate of oil flowing in a pipeline, in airplanes and in industrial applications.

- It is also used in scientific research where the flow rate of a fluid needs to be measured. Flowmeters can also be used to determine the flow rate of liquids that are emitted into the environment. For example, an annual flow element can be used to monitor the emissions of gases from a chimney.

- Annubar flowmeters are also important in agricultural and industrial production. They are used to determine the amount of input being used to automate the process or as a control system.

- Annubar flow meters can also be used in the mining industry to determine the flow of compressed air, blast furnace gas, and other liquids.

- It is widely used in electronic power, petroleum, water treatment, chemical industry, environmental protection, etc.

Annubar Flowmeter Advantage

- Annubar flowmeter has several advantages including:

- Its small size makes it suitable for insertion into small openings, therefore suitable for large pipeline flow rate measurement.

- Simple Structures, Easy Installation, Requires Less Maintenance.

- Low pressure loss.

- It can be used to determine the flow rate and velocity of a fluid in various multiple points.

- Annubar flowmeter has high accuracy as it has minimum blockage. Ensures that there are little or no pressure drops.

- The internal structure of the Annubar flow element provides a very high precision.

- The Anubar Flow Meter is resistant to corrosion and can be used in areas with high temperatures.

- Accuracy of inductive flow element is unaffected by wear and tear forces.

- Flow meters are also easy to install and come in a variety of designs.

- Wide range of applications, it can be used to measure gas, steam and liquid.

- An anubar flow meter should also be used in places where there is no snow or any material that can clog multiple ports, such as dust. However, there are manual and automatic purging

- systems that can help keep the flowmeter from clogging up.

- It is available for a wide range of pipe sizes.

- It is simple and economical to install.

- It provides negligible pressure drop.

- It can be placed in service under pressure.

- It can be rotated while in service, for cleaning action.

- It provides long term measurement stability.

Annubar disadvantage

- Unsuitability for operating dirty or sticky fluids.

- Limited operating data.

- Annubar has Single point measurement.

- Annubar is fragile

- In annubar DP signal is too low.

Read Also