Table of Contents

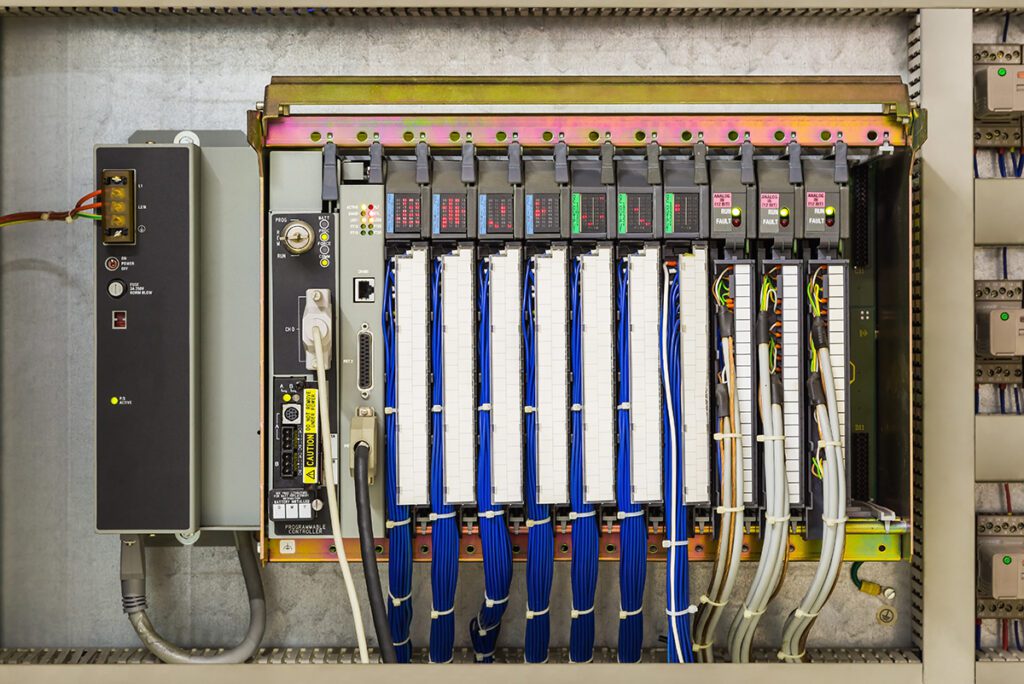

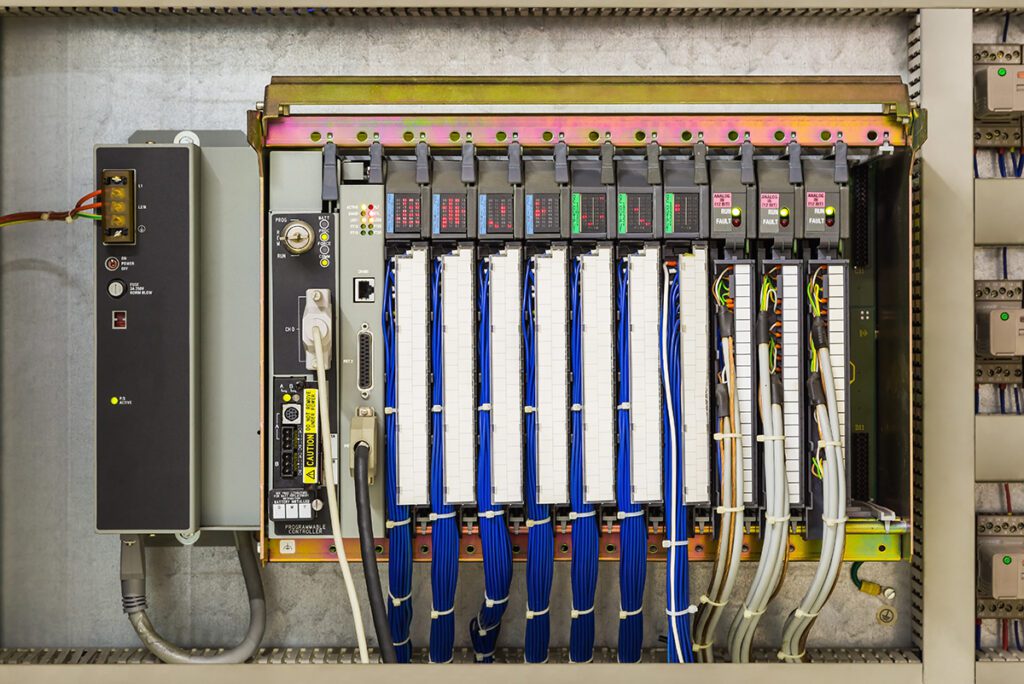

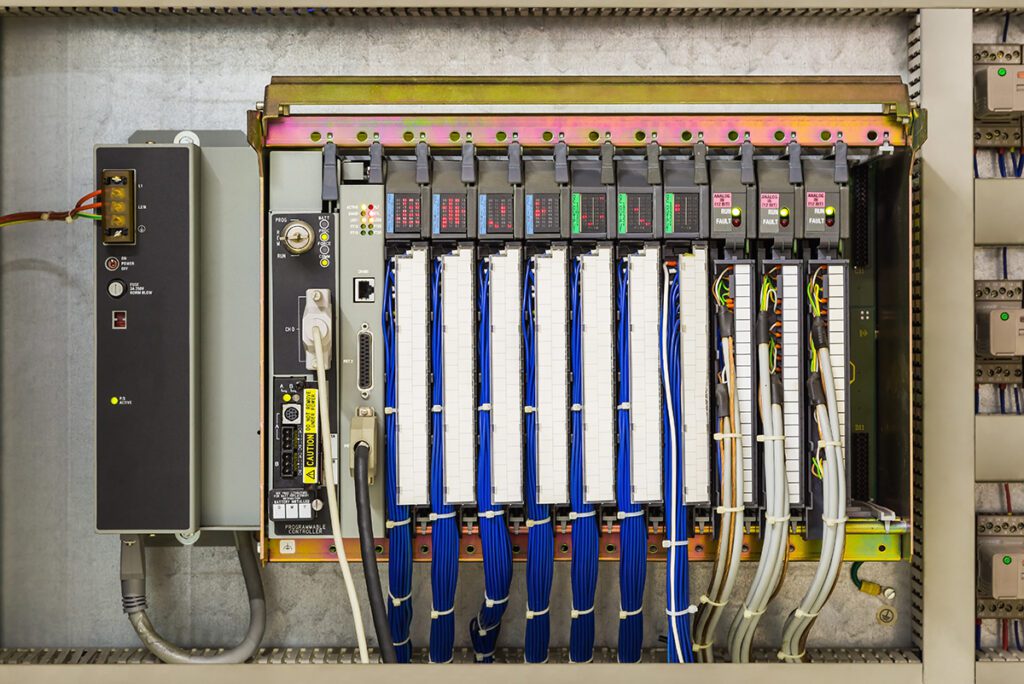

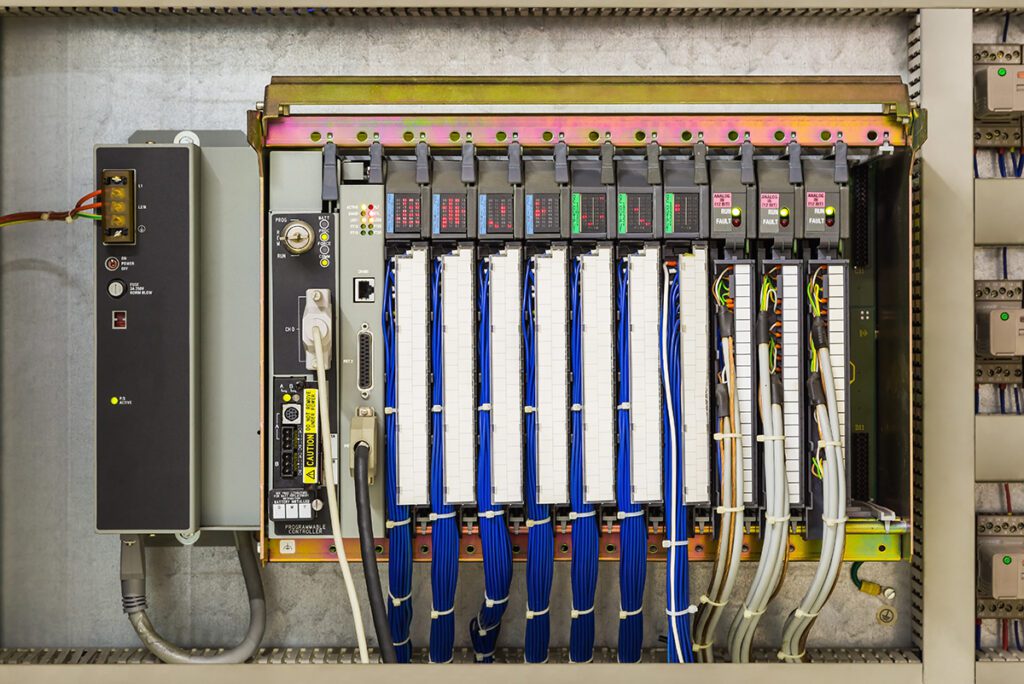

Allen-Bradley is a brand of Programmable Logic Controllers (PLCs) owned by Rockwell Automation, a company founded in 1903. Allen-Bradley PLCs are widely used in industrial automation and control systems to automate manufacturing processes, monitor and control machinery, and manage industrial data.

The Evolution of Allen-Bradley PLCs From Relay Logic to Digital Control

The first Allen-Bradley PLC was introduced in 1968, and it was a major breakthrough in industrial automation technology. Before the introduction of PLCs, manufacturing processes were controlled using relay logic, which involved numerous relays, timers, and other electromechanical devices. Relay logic was complex, expensive, and difficult to maintain. The introduction of PLCs changed everything.

PLCs were digital devices that could perform logic functions, just like relay logic, but they were much simpler, faster, and more reliable. The first Allen-Bradley PLC, the 1771, had 29 different modules that could be programmed to perform a variety of functions. The 1771 was a big success, and it set the stage for the development of even more advanced PLCs.

Allen-Bradley PLCs Models

Allen-Bradley is a brand of industrial automation equipment that provides a variety of programmable logic controllers (PLCs) for different applications. PLCs are essential components of modern manufacturing processes and are used to control and monitor machinery and processes in various industries.

Allen-Bradley offers several different models of PLCs that can be used for different applications. Some of the most popular models include:

-

CompactLogix:-

This is a series of small and mid-sized PLCs that are ideal for machine control and small to mid-sized applications. They are known for their high performance, scalability, and flexibility.

-

ControlLogix:-

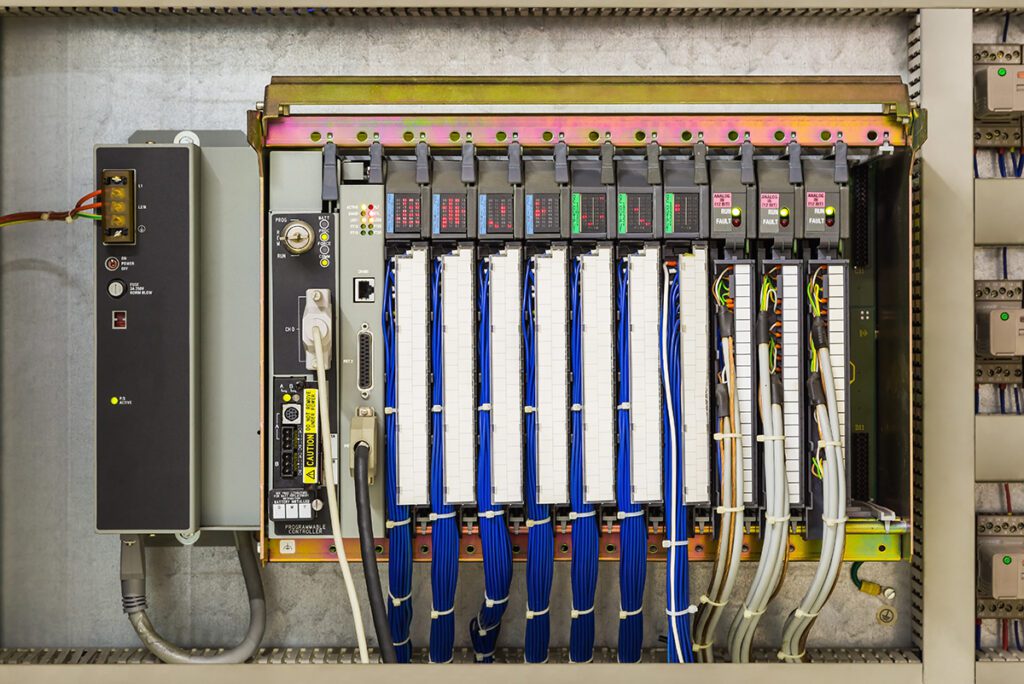

This is a series of large, high-performance PLCs that are used for demanding applications such as motion control, process control, and data acquisition. They are known for their advanced features and high processing speed.

-

MicroLogix:-

This is a series of small, low-cost PLCs that are ideal for simple machine control and small-scale automation projects. They are easy to program and can be used for a variety of applications.

-

FlexLogix:-

This is a series of modular PLCs that can be customized to fit the specific needs of an application. They are known for their flexibility and can be expanded as needed.

-

PLC-5:-

This is a series of legacy PLCs that are still in use in many industries. They are known for their reliability and durability, and are often used in applications that require long-term support.

All of these Allen-Bradley PLC models are designed to be easy to use and reliable, with features that make them well-suited for a variety of applications. They can be programmed using a variety of software tools, including Allen-Bradley’s own programming software, RSLogix, which is widely used in the industry.

Overall, Allen-Bradley PLCs are a popular choice for industrial automation due to their reliability, performance, and flexibility. Whether you are looking for a small, simple PLC or a large, complex system, Allen-Bradley has a model that can meet your needs.

Introduction of the ControlLogix PLC

The ControlLogix PLC was introduced in 1997, and it represented a major step forward in PLC technology. The ControlLogix was a modular PLC that could be configured to meet the needs of virtually any industrial automation application. It was based on a high-performance processor that could handle large amounts of data quickly and efficiently.

The ControlLogix was also highly scalable, which meant that it could be expanded as needed to accommodate changes in manufacturing processes. It was also designed with a modular architecture, which meant that different modules could be added or removed as needed to meet specific application requirements.

The Advantages of Allen-Bradley PLCs

Allen-Bradley PLCs offer many advantages over traditional relay logic systems. Some of the key advantages include:

- Flexibility: PLCs are highly flexible and can be programmed to perform a wide range of functions. This means that they can be used in a variety of applications, from simple to complex.

- Reliability: PLCs are highly reliable and can operate continuously for long periods of time without any problems. This means that they can help to minimize downtime and improve overall system performance.

- Scalability: PLCs are highly scalable and can be expanded as needed to accommodate changes in manufacturing processes. This means that they can be used in a wide range of applications, from small to large.

- Modularity: PLCs are highly modular and can be configured to meet the needs of specific applications. This means that different modules can be added or removed as needed to meet specific application requirements.

- Programmability: PLCs are highly programmable and can be easily configured to meet the needs of specific applications. This means that they can be used to perform a wide range of functions, from simple to complex.

Conclusion

Allen-Bradley PLCs have come a long way since their introduction in 1968. Today, they are widely used in industrial automation and control systems to automate manufacturing processes, monitor and control machinery, and manage industrial data. They offer many advantages over traditional relay logic systems, including flexibility, reliability, scalability, modularity, and programmability. As manufacturing processes continue to become more complex, Allen-Bradley PLCs will continue to play a critical role in industrial automation and control.

Read Also

- What is hvac | HVAC | HVAC System

- What is Printer ?

- Level transmitter | level transmitter types

- Limit switch | Limit switches