Table of Contents

Flow element- In a continuous chemical process control of material flow is essential, the flow of one variable may also control the other variable. Such as the temperature control of the system can be achieved by controlling/ regulating the flow of heating or cooling media. Many chemical process are sensitive to ratio of ingredient for proper reaction requires correct, the proportion of materials to achieve quality product. Product properties are affected by varying the ratio of raw materials flow, the fluid may be liquid, gas or solid, the accurate flow control is nearly essential. A knowledge of some basic characteristics of fluid and fluid flow is necessary for choosing best method of flow measurement which need to be considered includes Viscosity, density, specific gravity, compressibility, temperature, pressure and fluid viscosity, laminar or turbulent.

Various Methods of Flow Measurement.

Differential pressure method, Variable area method, Magnetic Flow meter, Positive displacement (Turbine meter), Target meter and Ultra sonic flower meter.

Differential Pressure Method:

In order to measure the rate of flow by differential pressure there must be method of creating two different pressure . This can be accomplished by placing a restriction in the pipe line that forces the fluid through the reduced area. The most common

methods of creating restriction in flow pipe line are: Orifice Plate (Concentric , Eccentric & Segmental are the type of orifice plates use, Their selection depends on the characteristic of the fluid that is to be measured.

Venturi Tube

It is a specially shaped length of pipe resembling two funnel joint at their smaller opening. (Concentric venturi , Eccentric Venturi & Duct Venturi).

When permanent pressure loss is primary importance in head flow measurement, the venturi tube deserves strong the velocity head and decreasing the pressure head. The flow rate remains statics in the throat section where there in no cross sectional dimensional change, but it decreases in the recovery section and the decrease velocity head is recovered as pressure. The relatively large recovery at this point results in a permanent pressure loss of any 10 to 25 % of the differential pressure across the tube.

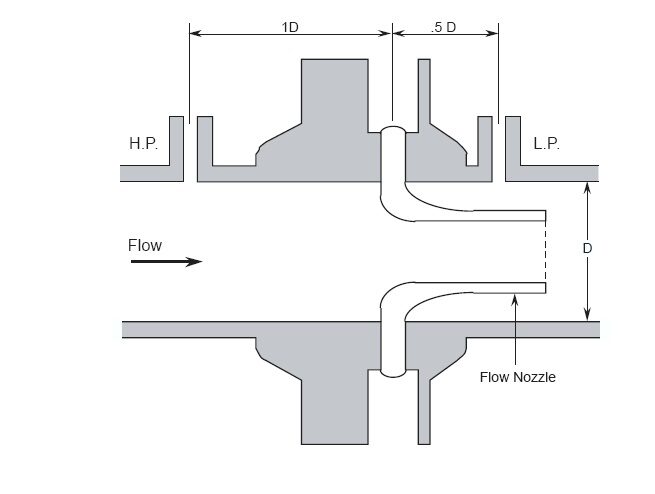

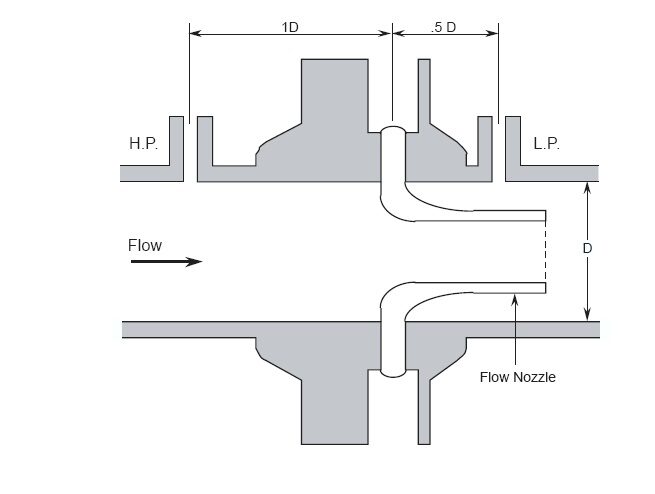

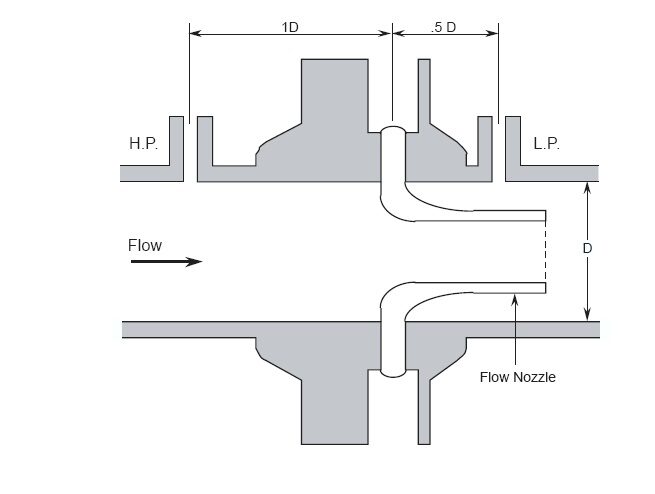

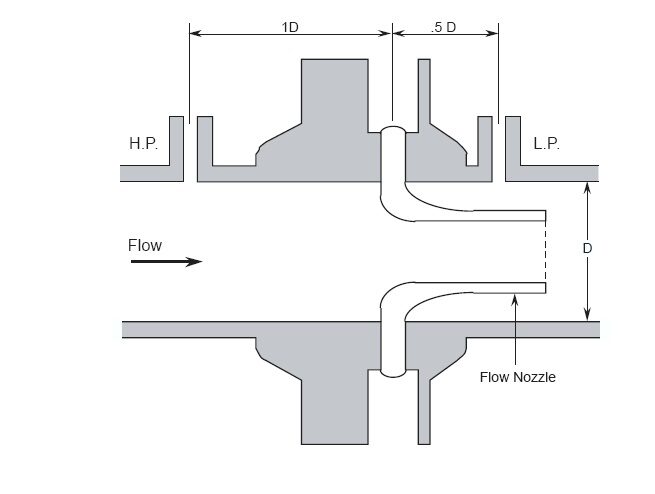

Flow Nozzle

It is the restriction in method resembles the entering the half of the venturi tube .

A flow nozzle is also called a half venturi.The flow nozzles are used for flow measurement at high fluid velocities & the more rugged & more resistant to erosion than the sharp edged orifice plate

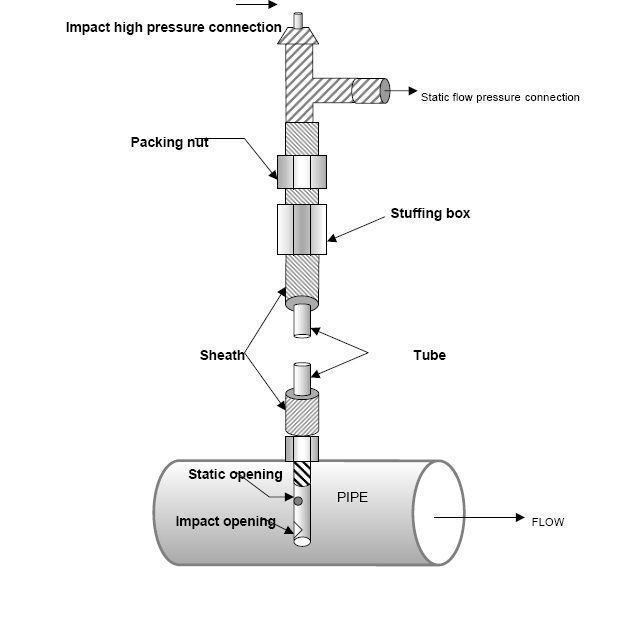

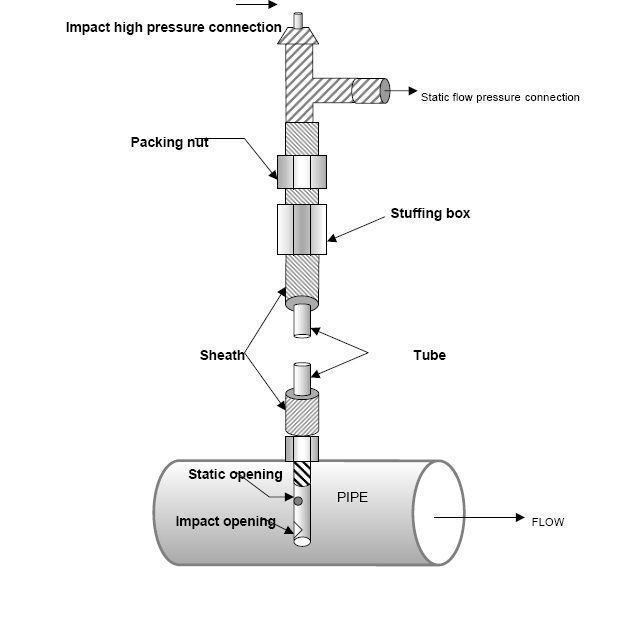

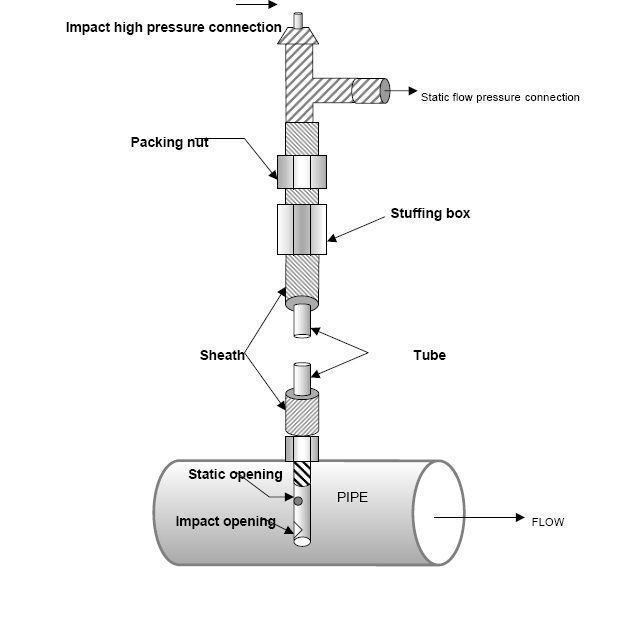

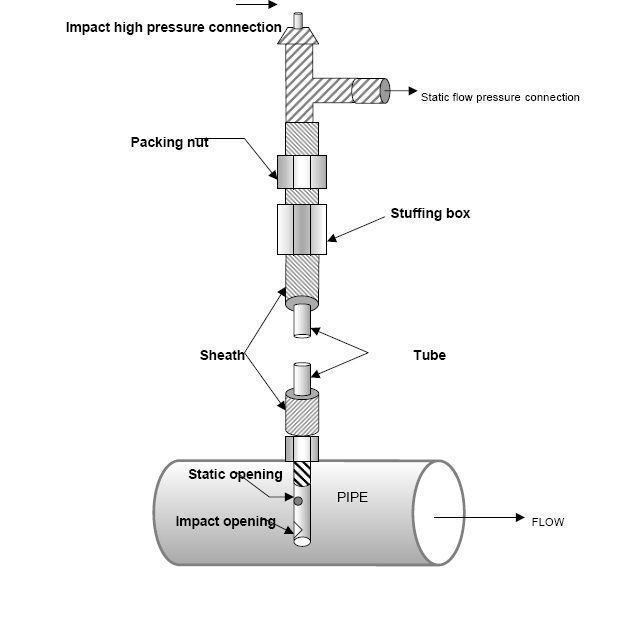

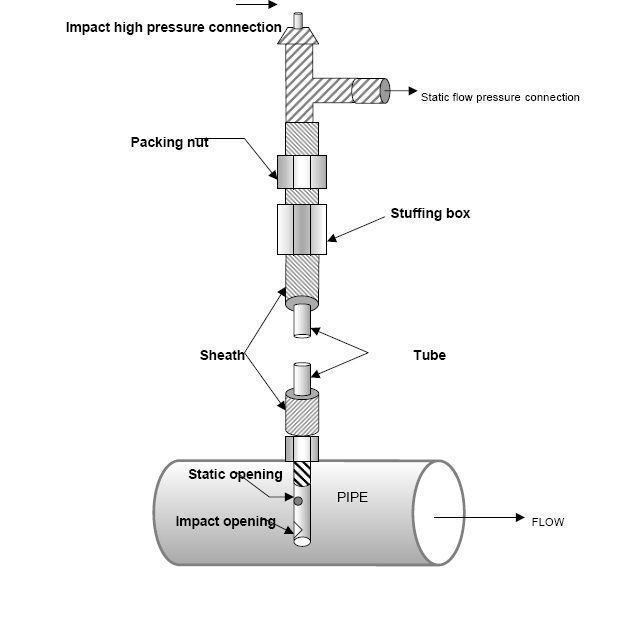

Pitot tube

Pitot tubes also utilize the principles captured in Bernoulli.s equation, to measure flow. Most pitot tubes actually consist of two tubes. One, the lowpressure tube measures the static pressure in the pipe. The second, the highpressure tube is inserted in the pipe in such a way that the flowing fluid is stopped in the tube. The pressure in the high-pressure tube will be the static pressure in the system plus a pressure dependant on the force required stopping the flow.

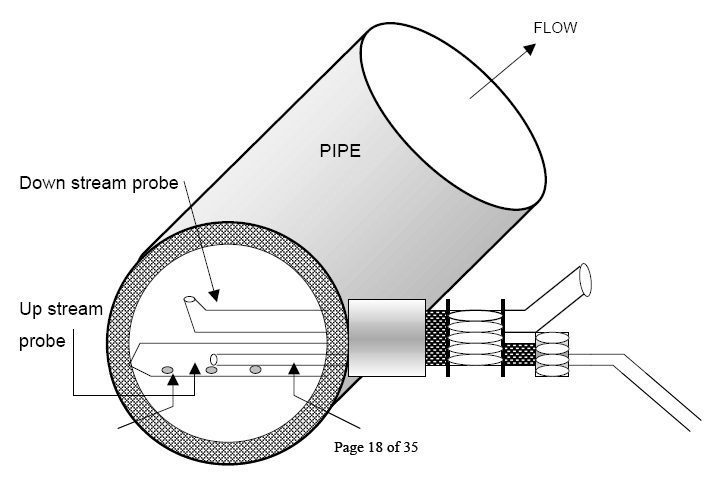

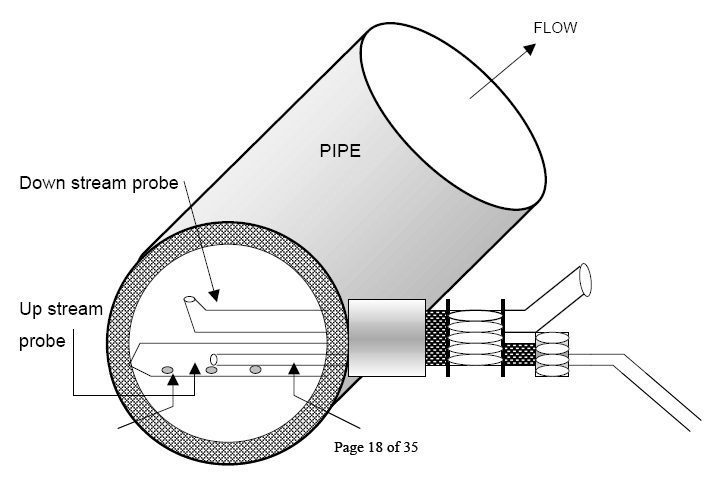

Annubar

An annubar is very similar to a pitot tube. The difference is that there is more than one hole into the pressure measuring chambers. The pressure in the high-pressure chamber represents an average of the velocity across the pipe. Annubars are more accurate than pitots as they are not as position sensitive or as sensitive to the velocity profile of the fluid.

Type of pressure taping connection across the restriction flow element

- Flange Taping: Normally located 1” from the upstream face of the orifice and 1” from down stream face .The flange tapin normally used in above 2” pipe size.

- Corner Taping: Particularly used for pipe size less than 2 inches.

- Vena contracta Taping: The upstream taping is located on pipe diameter from the orifice plate and downstream taping at vena contracta point of minimum pressure caused by restriction ; however the minimum pressure point varies with d/D (“ ID of pipe & “ d” is orifice bore diameter)

- Radius Taping: Tapings are located close approximation of Vena contracta e. one pipe diameter up stream and half pipe diameter from the orifice .

- Pipe Taps: The Tapings are located 2 &1/2 pipe dia. Upstream and 8 pipe dia. down stream.

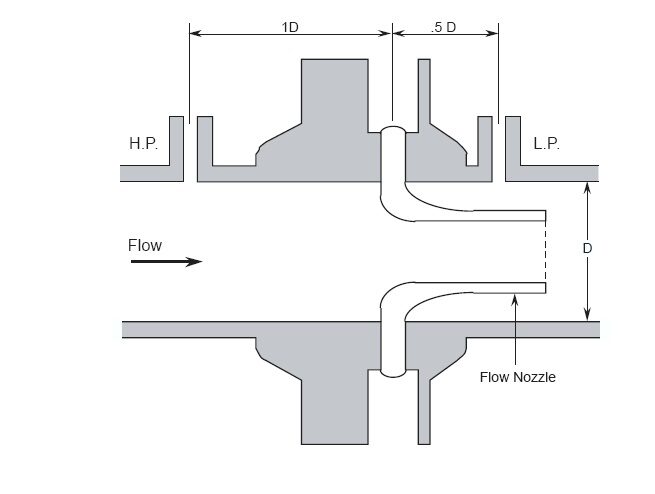

- Pressure taping in Venturi tube: Tapings are located one-half pipe diameter upstream of the inlet cone and at the middle of the throat section and for flow nozzle D & D/2 from the inlet face of the nozzle.

Variable area meter:

In variable area flow element rotameter is used to measure flow rate . the rotameter in which the area is varied by a float in a tapper tube where as the pressure differential kept constant.

Magnet Flow meter :

It utilize the principle of Faraday’s Law of induction, which states that an electrical potential is developed by a relative motion at the right angle between a conductor and a magnetic field. Here the conductor is electrically conductive moving fluid.

The meter consist of an electrically insulated tube or pipe with a pair of electrodes mounted opposite each other and flush with the inside walls of its tube. electrical coils are around the tube so that a magnet field is generated in a plane mutually perpendicular to the axis of the meter body and to the plane of electrodes. The fluid inside the pipe can be conceive as a group of parallel conductors at different velocity. The voltage generated by these moving conductors is the average of many conductors, so that the instantaneous voltage developed is proportional to the average fluid velocity, producing a true volume measurement of the fluid. Some feature of magnet flow meter are No obstruction in flow, Minimal pressure drop, Measurement of difficult fluid flow is possible, Pipe configuration is not critical. Bi-directional flow measurement is possible. Meters are unaffected by velocity, density, temp. pressure or fluid turbulence.

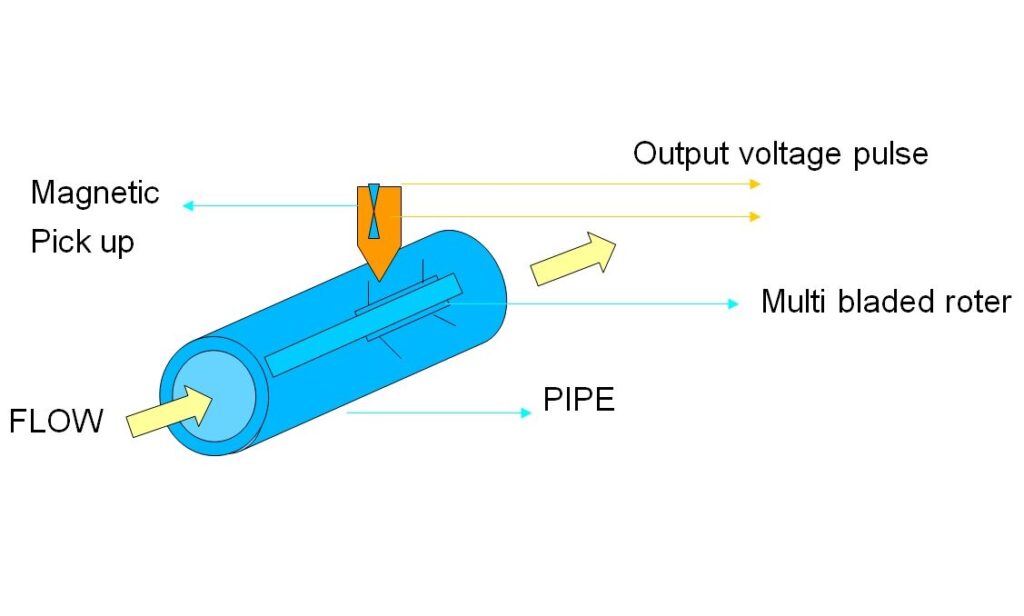

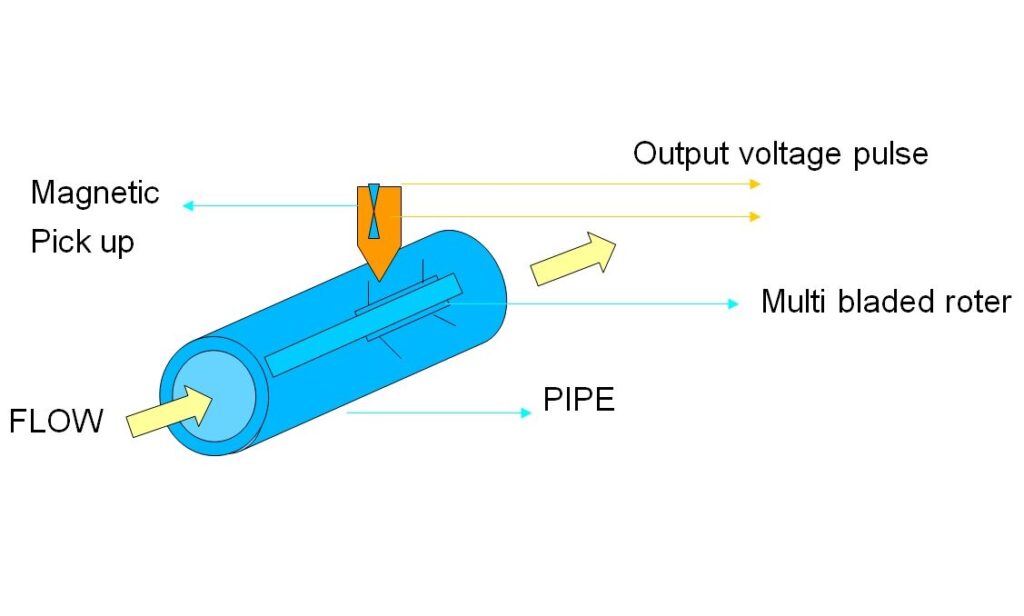

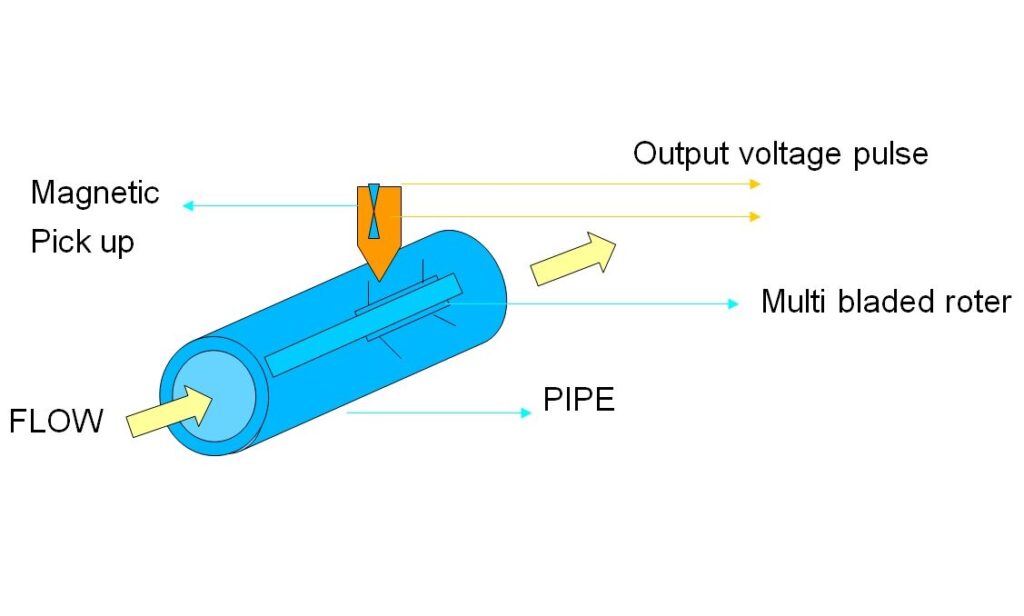

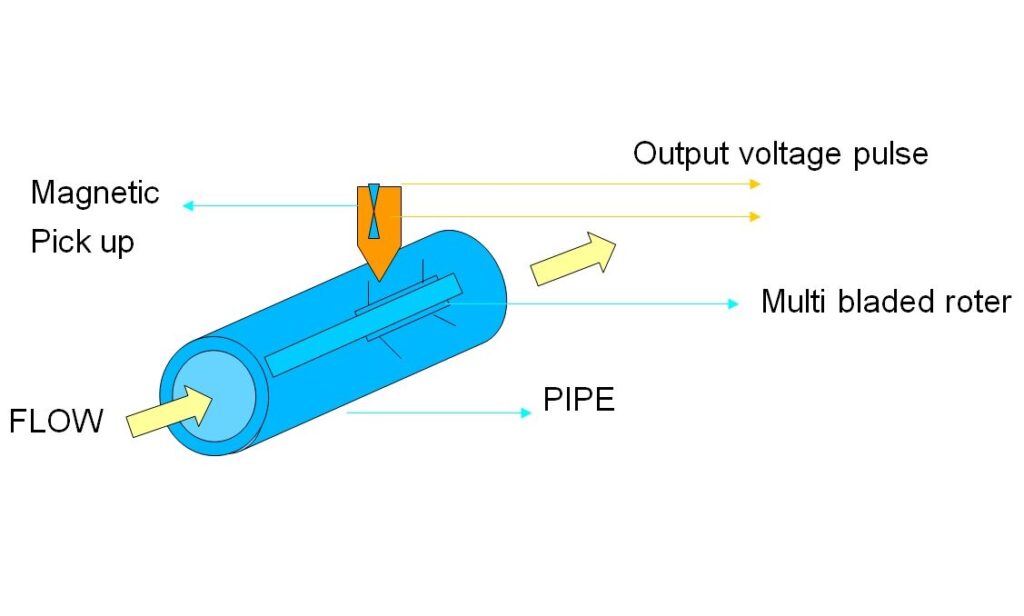

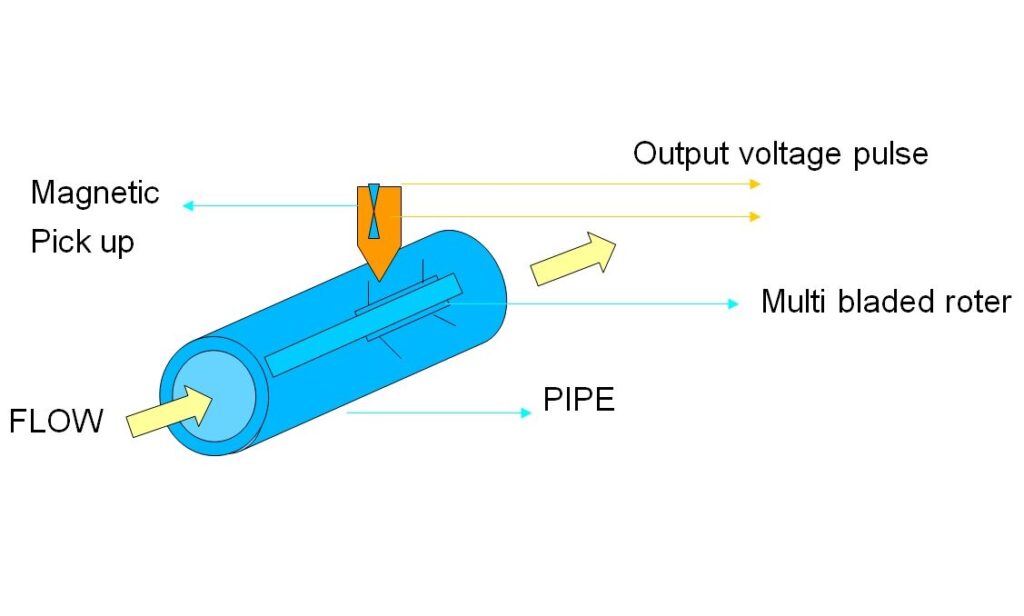

Turbine Flow-meter :-

Turbine flow-meter consist of a straight flow tube within which a turbine orphan is free to rotate about its axis which is fixed along the center line of the tube . The velocity of the flowing stream impart a force to the turbine to rotate at a speed proportional to flow rate . A magnet pick up system senses when a rotating blade passes under it and a A.C. pulse is induced Each pulse represent a definite flow quantity.

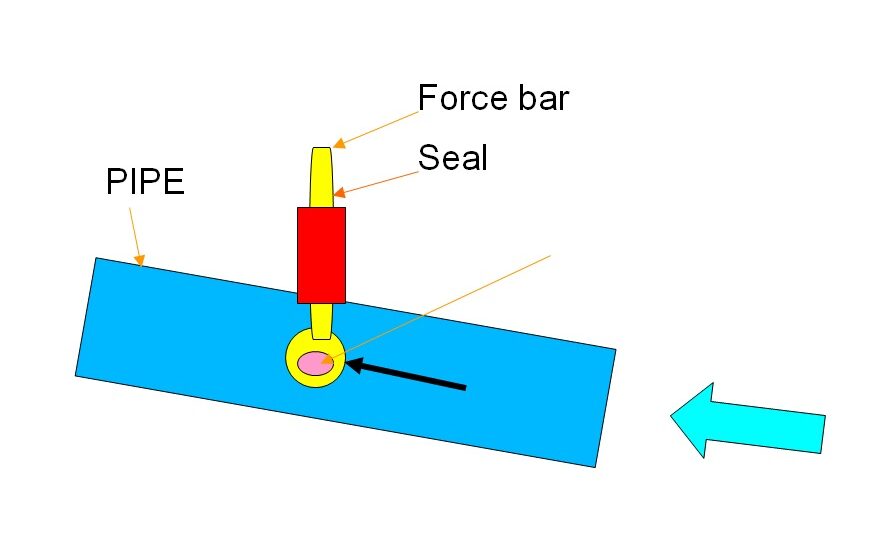

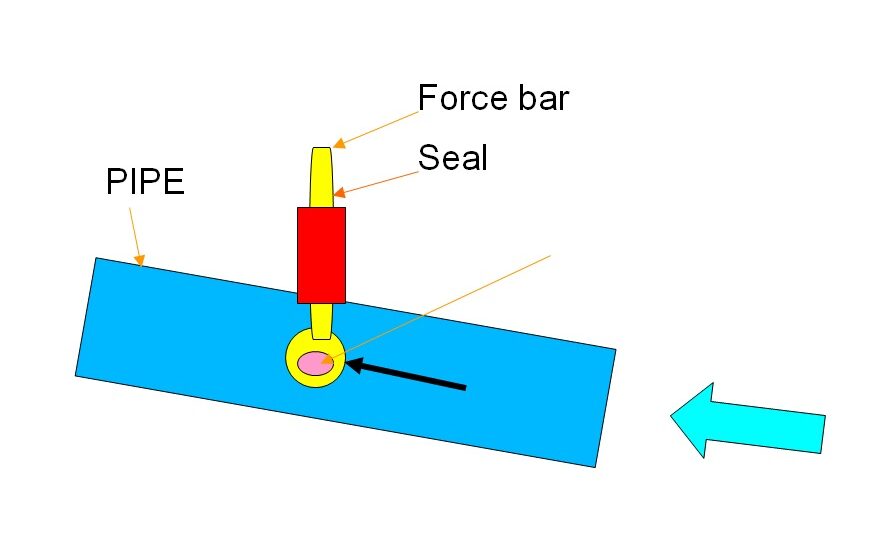

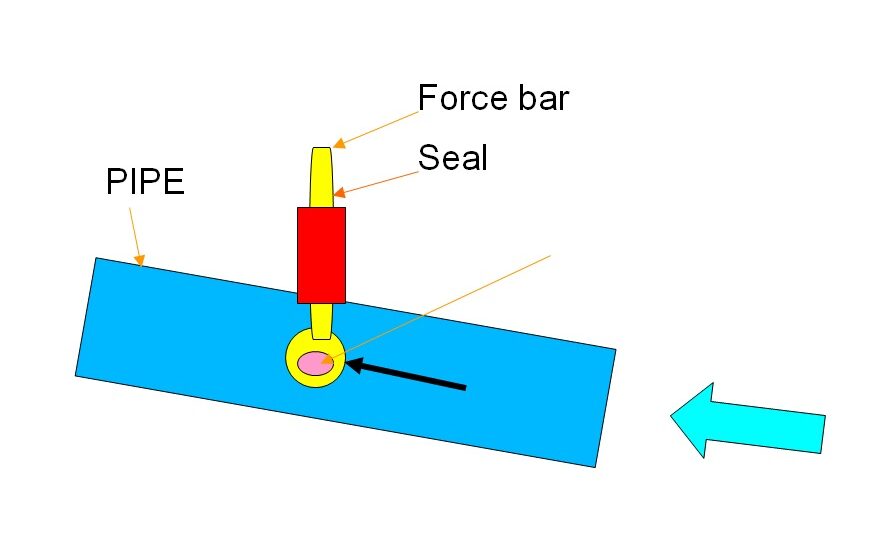

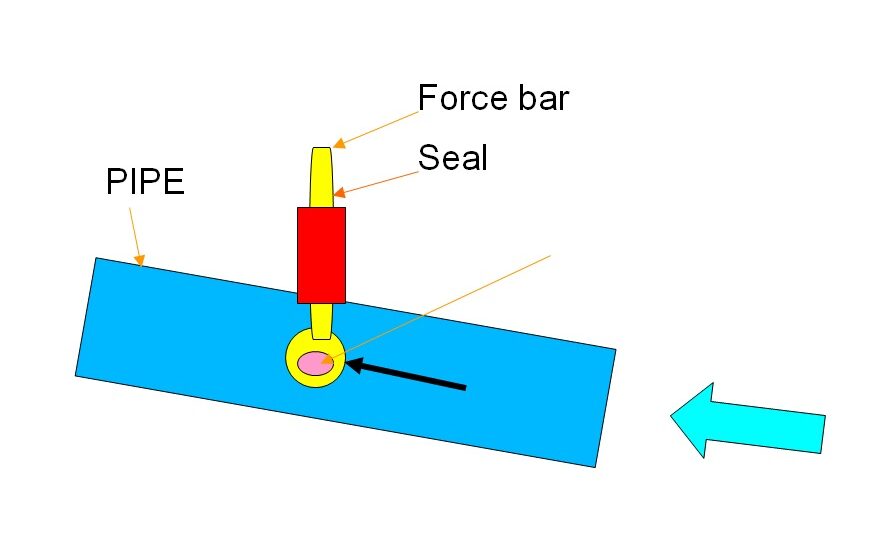

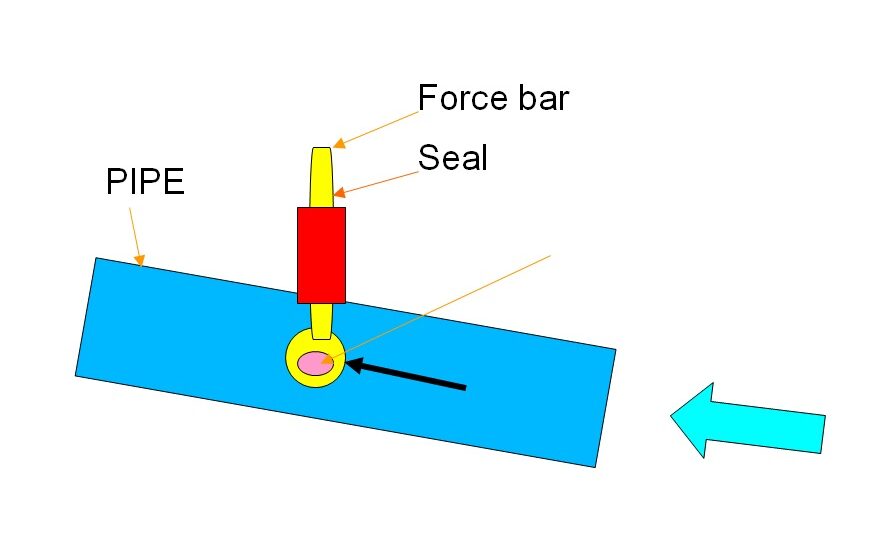

Target flow Meters :-

It measures flow by measuring the force on the disc or target centered in the pipe with the plane of the target at right angle to the direction of fluid flow . The flow develop the force on the target which is proportional to the square of flow. The force is sensed by Electronic /pneumatic transmitter for remote monitoring and controlling.

Ultrasonic flow meters :-

Many flow measurements can be made by sampling velocity measurements in the pipe . When velocity information is obtained, an average velocity multiply by pipe cross- sectional area gives the volumetric flow rate. Three type of sonic meter are Broadband noise sensor, invasive and noninvasive Doppler shift device. High ultra sonic frequency is generated whenever fluid or granules move. A sensitive microphonic sensor is attached to the pipe, and signals are electronically integrated to provide measurement. accuracy is +-1% and repeatability of the value is about 1% .

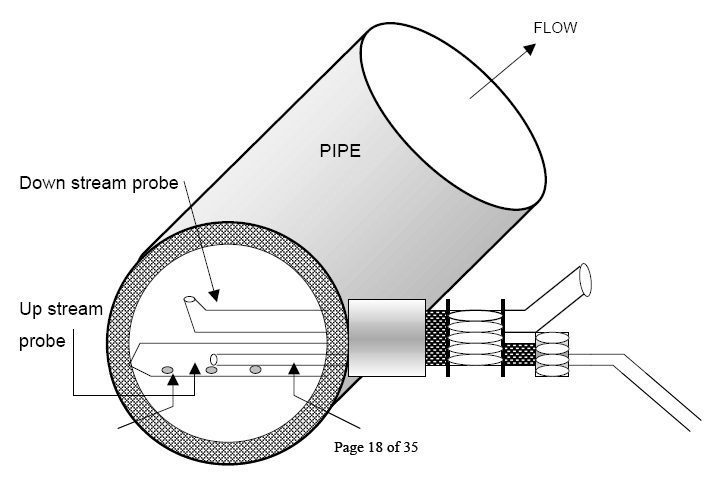

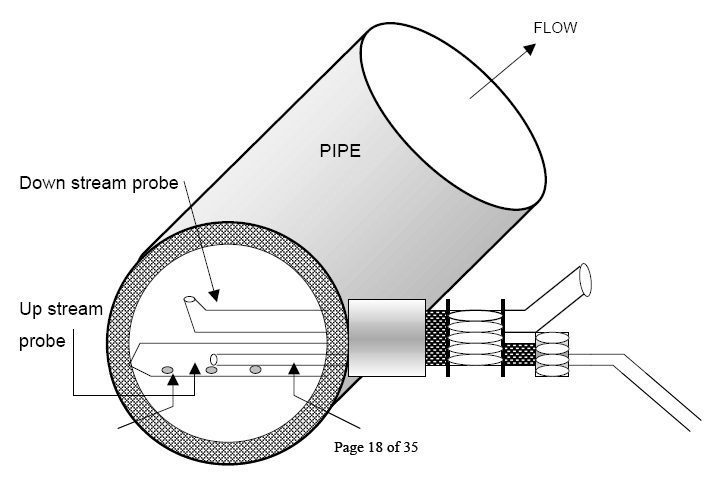

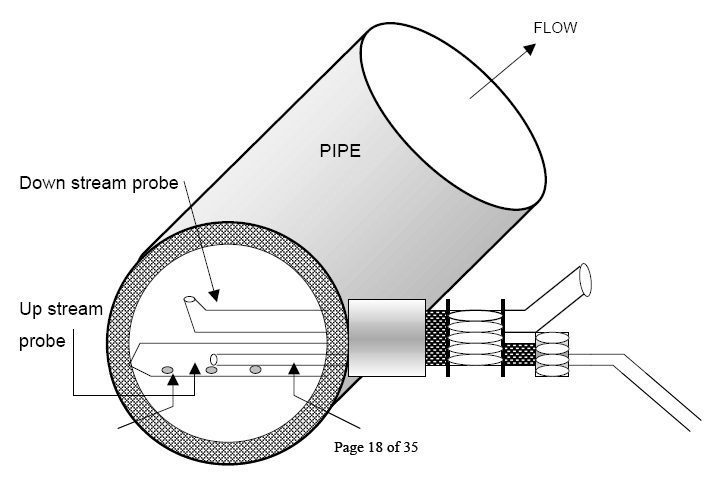

· Time difference type Ultrasonic Flow meter:-

This instrument measures flow by measuring the time it takes for an ultrasonic wave to cross a pipe section and against the flow of liquid within the pipe.

· Doppler flow meter

In a Doppler flow meter, an ultrasonic wave is projected at an angle though the pipe wall into the liquid by a transmitting crystal in a transducer mounted on the outside of the pipe.

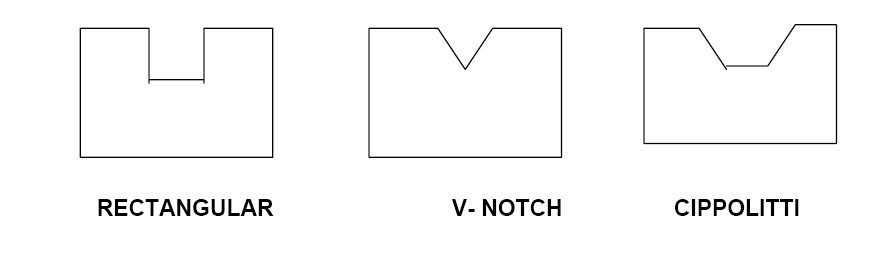

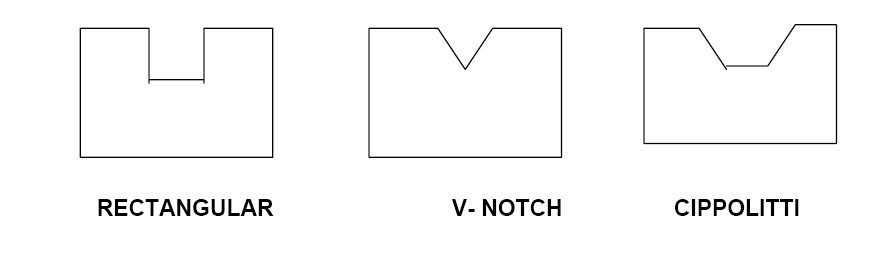

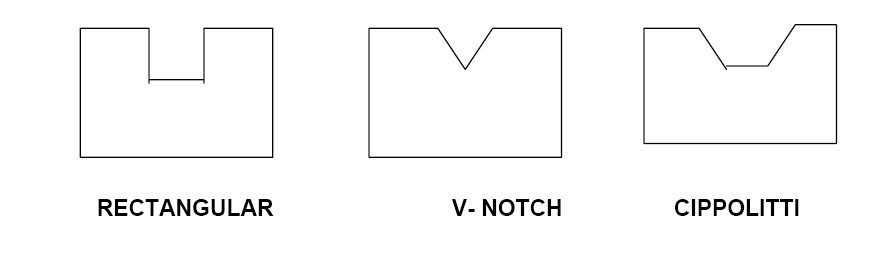

Open channel flow meter

Open channel flow meters check the height of the liquid and are used with flows exposed to open air.

Spring and piston flow meters measure annular flow through an orifice that is formed by a tapered cone and piston. The scales are based on the gravity of the fluid, where oil is 0.84 and water is 1.0. They have a simpler design and are an alternative to rotameters because they can be easily installed to transmit electrical signals.

Flow switches are not flow meters or flow element but simple mechanical devices for monitoring the flow of air and liquids. They are set at a predefined level and are activated when the level fluctuates. Once activated, they remain on until the system error is corrected.

A digital flow meter is defined as any flow measurement instrument with a digital display. A common digital meter is used by electricity companies to measure the flow of electricity into your home and sends your usage data to the electric company, which uses the data to bill you.

Positive Displacement Flowmeter:-

In many different type flow element , the pd flowmeter is more important. The positive displacement flow meter is the only flow measuring technology to directly measure the amount of fluid passing through a flow meter. It is the best technology for the measurement of clean liquid, ‘PD’ or positive displacement flowmeter is a versatile and cost effective choice for a wide range of applications. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber. This can be compared to repeatedly filling the beaker with liquid and pouring the contents into the aisle, while counting the number of times the beaker is filled.

Thermal Mass Flow meter

Thermal mass flow meters or flow element apply the thermal dispersion principle whereby the rate of heat absorbed by a process fluid flowing in a pipe or duct is directly proportional to its mass flow. In a typical thermal flow meter a gas flowing over a source of heat absorbs heat and cools the source.

As the flow increases, more heat is absorbed by the gas. The amount of heat released from the heat source is proportional to the mass flow of the gas and its thermal properties. Therefore, the measurement of heat transfer supplies the data from which the mass flow rate can be calculated.

Other Method of flow measurement:-

There are various other methods of flow measurement throw various flow element are available. They are

Vortex meter, Swirl meter, Oval gear meter, Thermal flow meter, Mass flow meter,

Nuclear magnetic resonance meter, Angular momentum flow meter etc

Read Also