Table of Contents

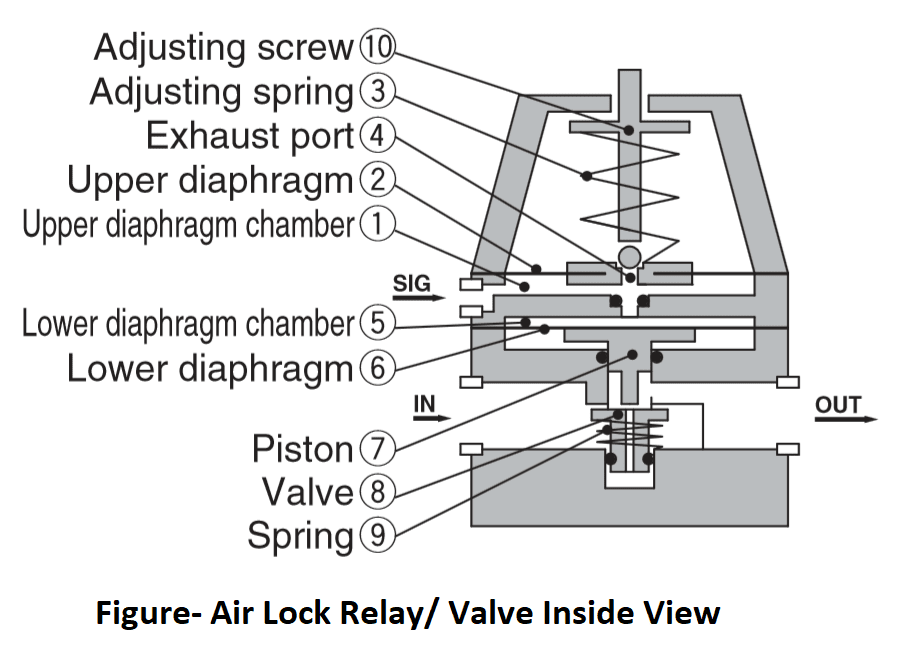

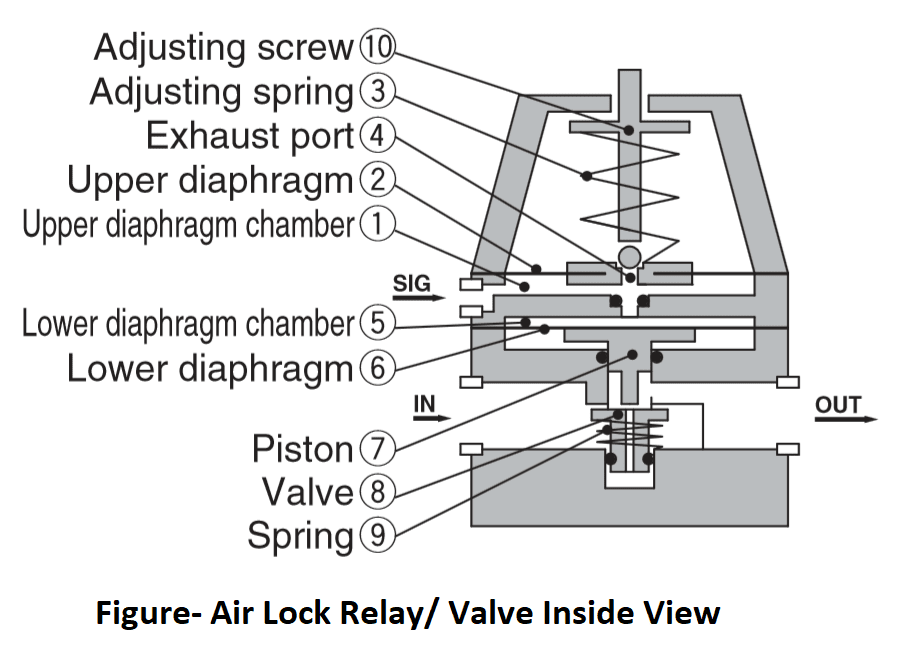

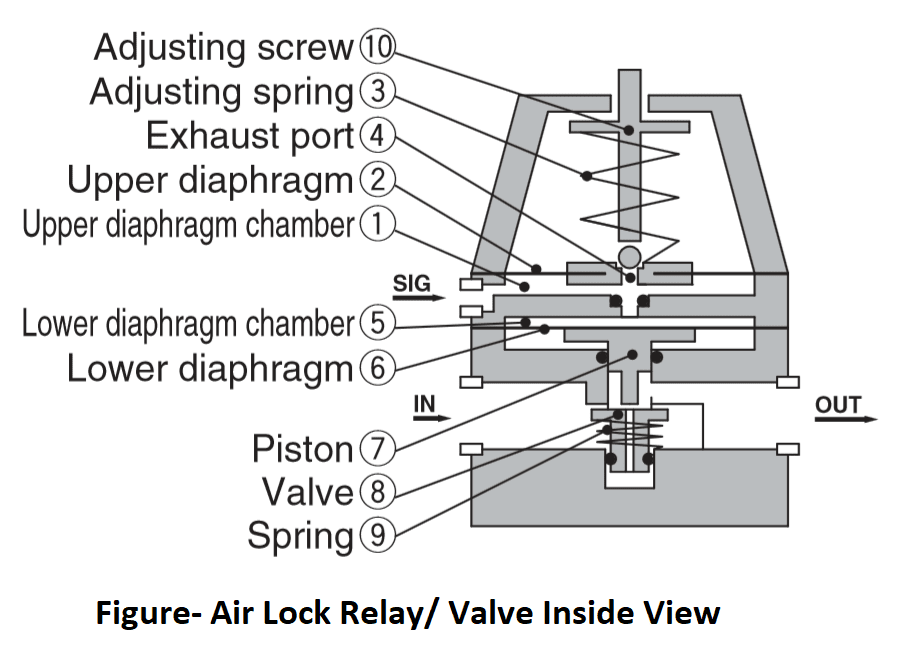

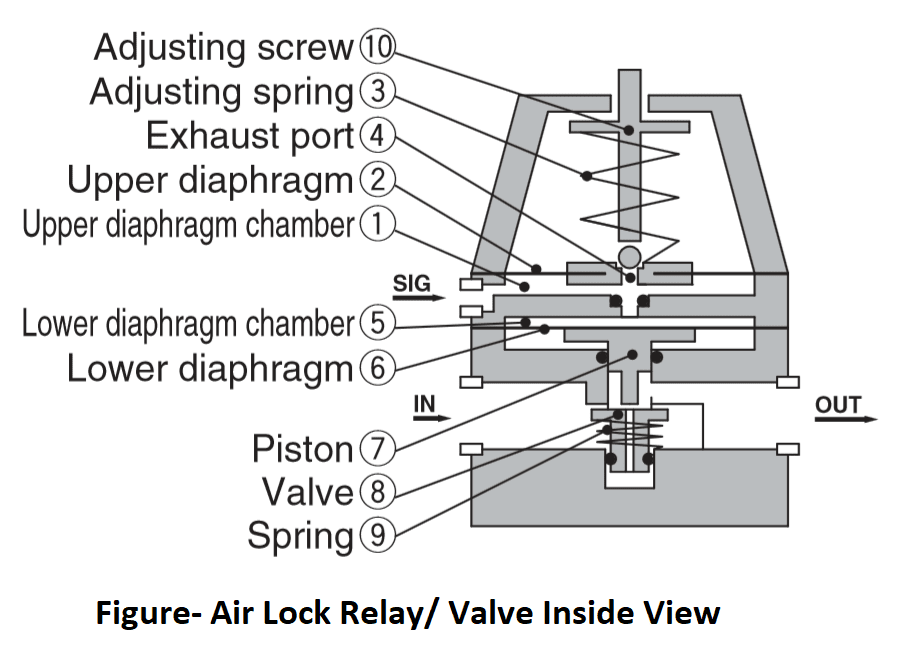

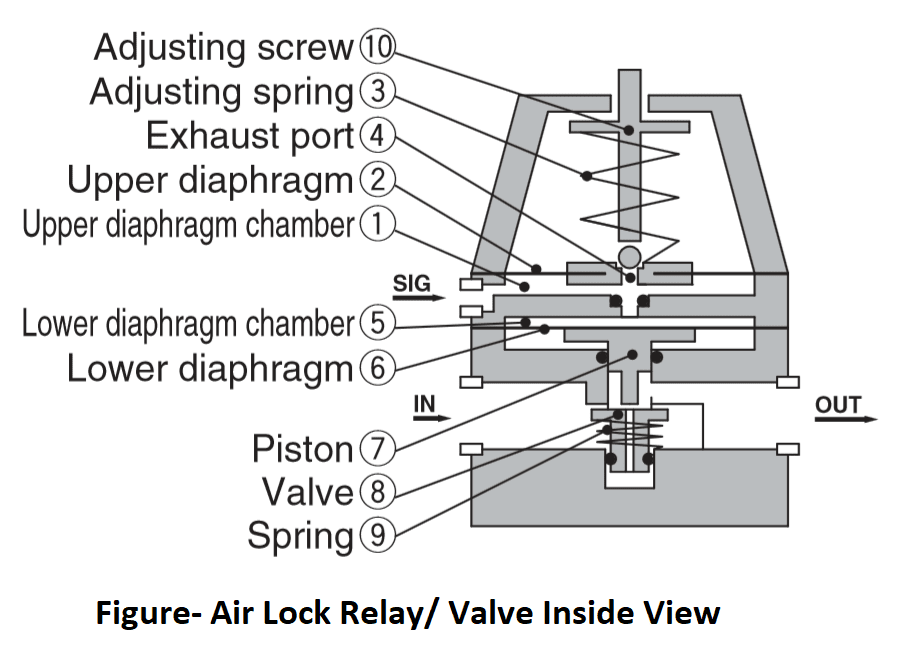

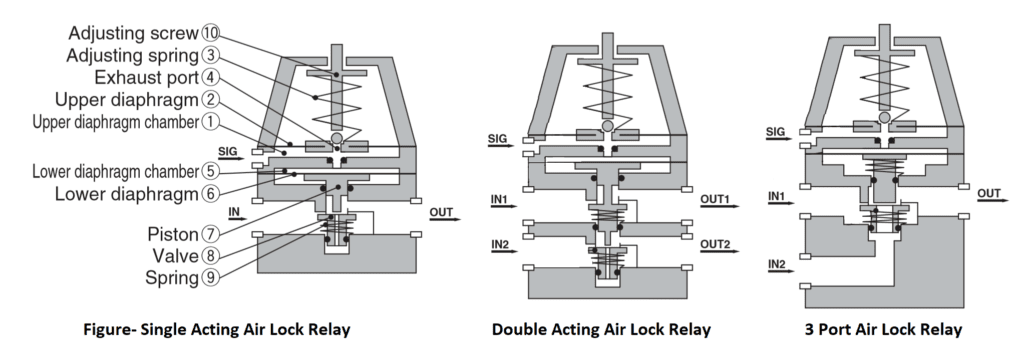

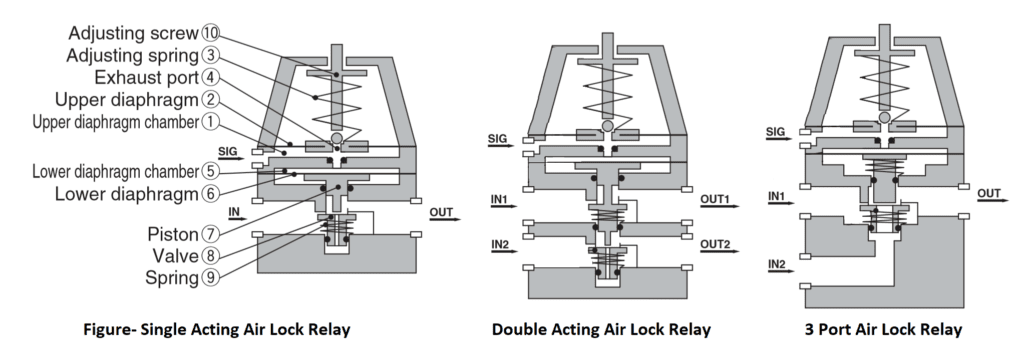

Air Lock valve (SMC) is used to hold the operating air inside actuator chamber to not make any disturbance in valve opening when any Pneumatic air supply or source failure occurs in the air operated process control line. A lock up relay is showing in figure-

Wheather the valve is set for direct acting or reverse acting, it is determined by consideration to hold the valve position in the event of air failure, to maintain the safety of process either by opening or closing of control valve. An air lock relay/ valve is used when it is required that the air pressure to the actuator be automaticlly held on same pressure. When supply pressure drop below a pre-set value, the air lock relay automaticlly lock the air piping between the instrument and the control valve, and causes the control valve to hold its position until air failure is rectified.

Working Principle

To understand working principle, an exploded diagram of Air lock relay is showing below-

The signal air pressure enters the upper diaphragm chamber to generate a force. When this force is larger than the force generated by compressing the adjusting spring, the upper diaphragm is pushed up, the exhaust port is closed, and the signal air pressure enters the lower diaphragm chamber and acts the lower diaphragm. This pushes down the piston to open the valve. Thus the flow path between IN and OUT is opened. If the signal air pressure drops to a level below the set pressure for some reason, the upper diaphragm is pushed down, the pressure inside the lower diaphragm is exhausted from the exhaust port, and the valve is closed by the force of the spring. At this time, IN and OUT are shut down lock up relay. Here, the set pressure is adjusted using adjusting screw.

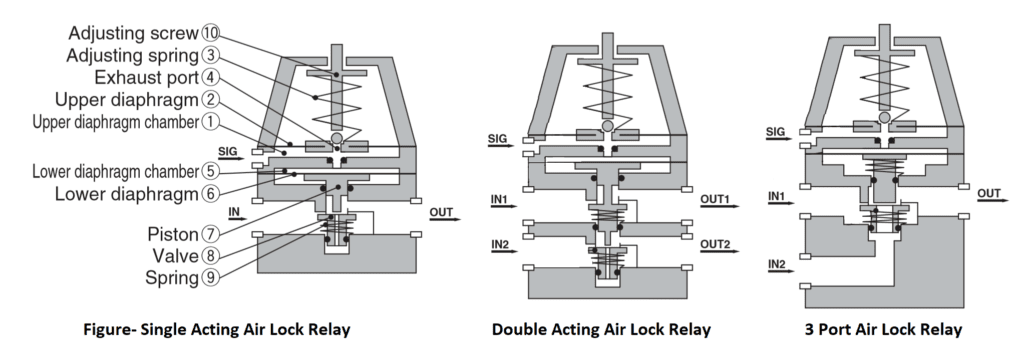

There are three type of configuration exist in Air Lock Relay/ Valve-

- Single Acting or One port Air Lock relay (for single acting actuator)

- Double Acting or Two Port air lock relay (For Double Acting Actuator)

- Three port air lock relay (Changes the supply port if failure occurs)

Single Acting or One port Air Lock relay

Single acting Air Lock Relay is an instrument used in Pneumatically operated single acting (spring return) actuators and power cylinders to hold its position (to remain in stay put condition), in the event of air failure or if the air pressure drops below the preset pressure. The airlock relay resets automatically to auto mode when air pressure restores. It is connected between the positioner and the actuator.

Double Acting or Two Port air lock relay

Double acting Air Lock Relay is an instrument used in Pneumatically operated double acting actuators and power cylinders to hold its position by locking pressure of both the ports (to remain in stay put condition), in the event of air failure or if the air pressure drops below the preset pressure. The airlock relay is connected between the positioner and the actuator.

Three port air lock relay

When a Three port air lock relay is used, In case of the signal air pressure drops below the set pressure for some reason, IN1 and OUT are shut down, and the flow path between IN2 and OUT is opened.

Read Also:-