Table of Contents

Capacitive Level Switch

Capacitive level switch is sensors that, at a particular liquid, powder, or bulk level, produce an electrical contact. They have traditionally been used for non-metallic materials in the plastics, chemical, wood, ceramic, and glass, as well as the packaging industries. Some models don’t require any maintenance.

Working Principle of capacitive level switch

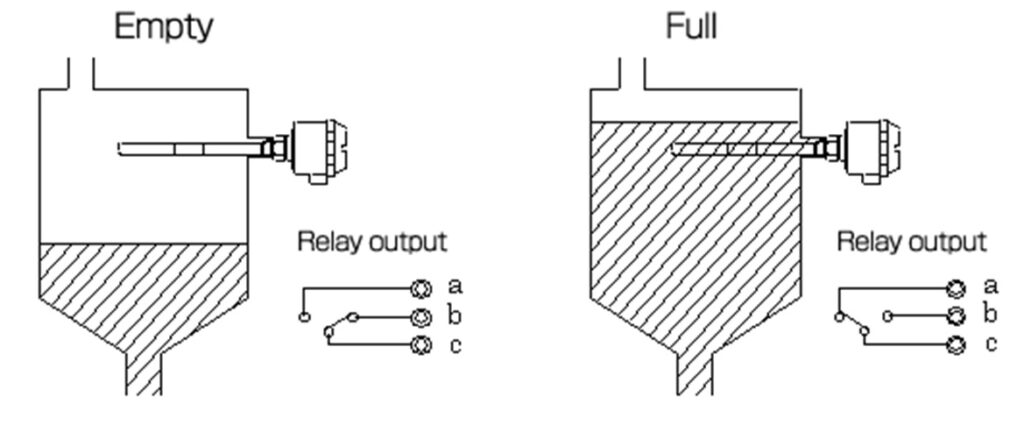

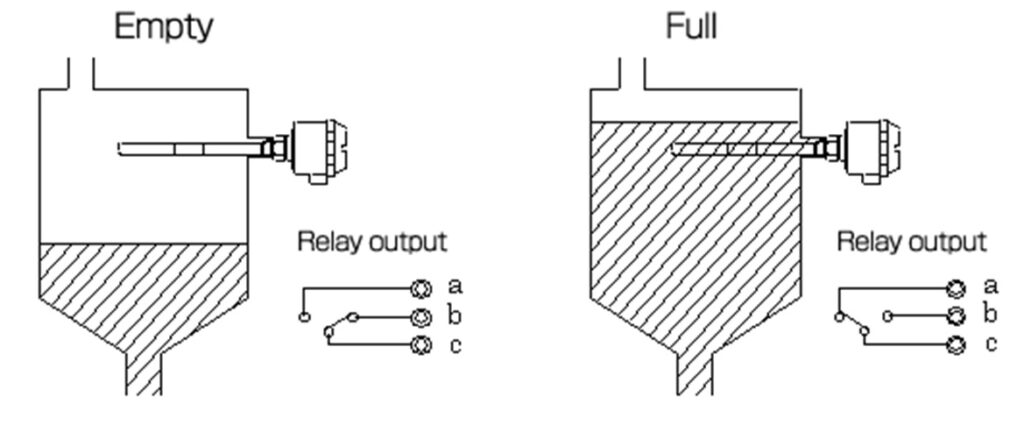

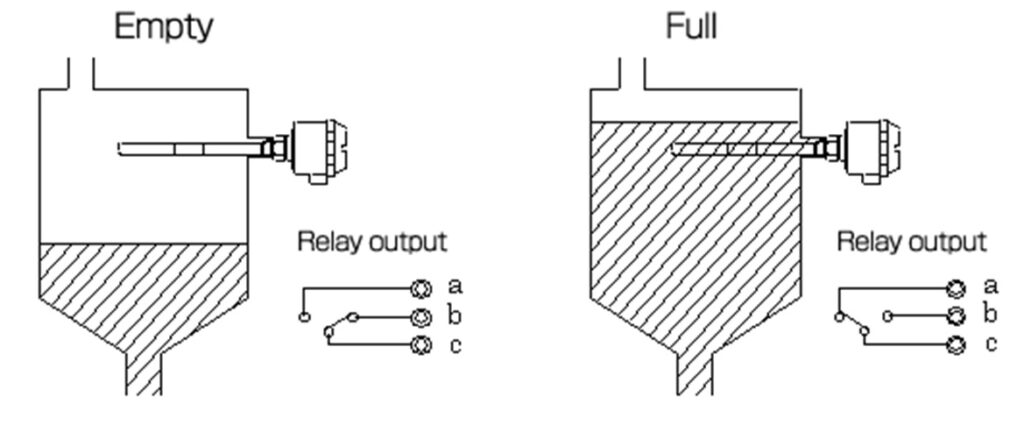

The capacitive level switch detects the presence of material when it comes in contact with the electrode and sends an output signal via a relay. The electrode can be mounted in either a horizontal or vertical configuration.

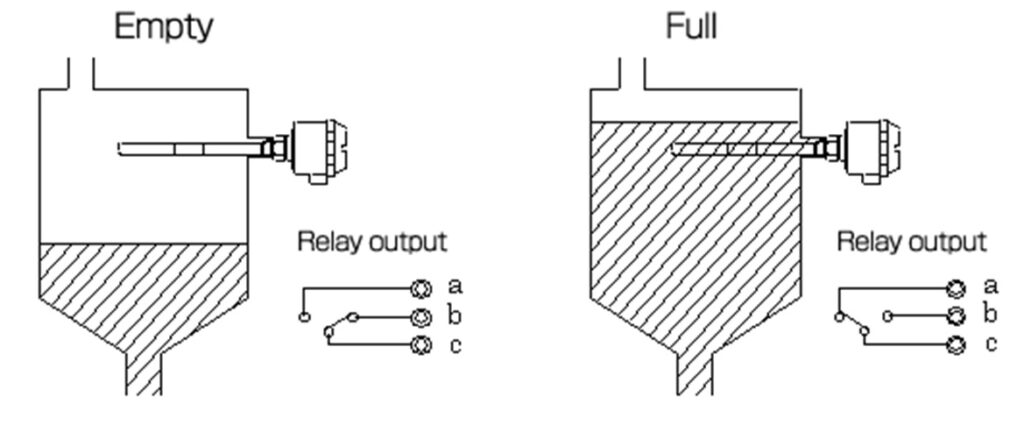

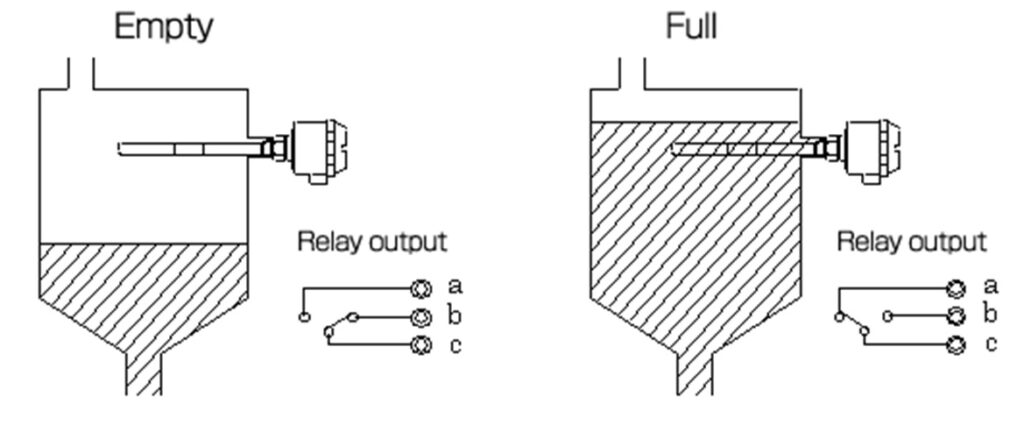

To determine the level, the switch measures the electrical difference between the states of empty and full material. When a material is empty, the detecting electrode and the grounding electrode’s resistance statuses are infinite, and the capacitance is specific.

When a substance is put into a vessel, the electrode fills up (gets full), changing the resistance and capacitance between the detecting electrode and the grounding electrode. This change is recorded by the switch, which then produces digital outputs.

Measuring Principle

A capacitor made up of the metal wall and an insulated metal probe set in a metal container continuously increases in capacitance as the medium level rises. A medium with a consistent permittivity is therefore necessary for capacitive measurements.

Level monitoring of liquids, granular solids, conductive and non-conductive medium is possible because to the straightforward and durable construction (as a rod or rope sensor).

The two electrodes of a capacitor are the measuring sensor and the metal container wall. The dielectric constant of the medium causes the capacitance to fluctuate as the level rises.

Advantages of Capacitive level switch

Following are the main advantages of capacitive level switch..

Installation and use are simple.

Connect and play.

Flexible application

Also intended for use with sticky media.

Active compensating for buildup.

Any location may be used to place the capacitive level switch.

Versions with full insulation can also measure corrosive liquids.

Low-cost point level detection for operation that requires no maintenance.

Universal 18-55V DC or 90-265V AC power supplies is required.

Up to 250 C is the application temperature range.

Disadvantages of Capacitive level switch

It is extremely sensitive to changes in environmental factors like temperature, humidity, and so on. The performance can suffer as a result.

Compared to measuring resistance, measuring capacitance is challenging.

Applications of capacitive level switch

Some important applications of capacitive level switch are given below.

In sugar Industry: Sugar is a byproduct of the extraction process that sugarcane goes through. A vital step in the production of sugar, solid waste, and sludge is the extraction of the sugar. In order to prevent material loss, level measuring tools are preferred to keep track of solid waste. Capacitance level switch helps the user to visualize measuring values and switching points.

In food processing industries: In a word, food processing is the fundamental preparation of food or its transformation into another form. Typically, it can transform fresh raw materials into food in these businesses. To prevent material filling, the production passes through a variety of automated processes. A capacitive level switches are available with pump control logic to regulate the automated process and turn on/off the motor according to switching conditions to handle these kinds of circumstances.

In Glass & ceramics Industries: However, normal processing involves storing raw materials like limestone, sand, and iron in sizable hoppers and silos under certain operational conditions depending on the type of glass being manufactured. To effectively manage raw materials, this storage needs to be level monitored. To address the overfill and dry run conditions, the capacitance level switches are used with two-point switching.

Read Also:-

Remote seal DP transmitter Calibration

Related Search:-

Working principle of tuning fork Type Level Switch

Working principle of tuning fork Type Level Switch

Ask Questions

Ask Questions

Working principle of ultrasonic type Level Switch

Working principle of ultrasonic type Level Switch

Working principle of Paddle type level switch

Working principle of Paddle type level switch

Control Valves Accessories

Control Valves Accessories