Pressure measurement will examine the theory and operation of pressure sensor (bourdon tubes, diaphragms, bellows, forced balance, and variable Capacitance). It also covers the variables of an operating environment (Pressure, temperature) and the possible modes of failure.

What is pressure?

The pressure is a force per unit area exerted by a fluid perpendicular to a boundary (as opposed to shear stress, which is exerted parallel to the boundary.)

PRESSURE UNIT:

Pascal,Bar,torr,PSI,Kg/cm2,mmWC,mmHg.

Example reading:

1 Pa = 1 N/m2 = 10−5bar = 10.197×10−6 at = 9.8692×10−6=atm =7.5006×10−3 = torr=145.04×10−6 psi Etc.

The SI unit for pressure is the pascal (Pa), equal to one newton per square meter (N·m−2 or kg·m−1·s−2). This special name for the unit was added in 1971; before that, pressure in SI was expressed in units such as N/m². When indicated, the zero references is stated in parenthesis following the unit, for example, 101 kPa (abs). The pound per square inch (psi) is still in widespread use in the US and Canada, notably for cars. A letter is often appended to the psi unit to indicate the measurement’s zero references; psia for absolute, psig for gauge, psia for differential, although Pressure measurement 3 this practice is discouraged by the NIST.

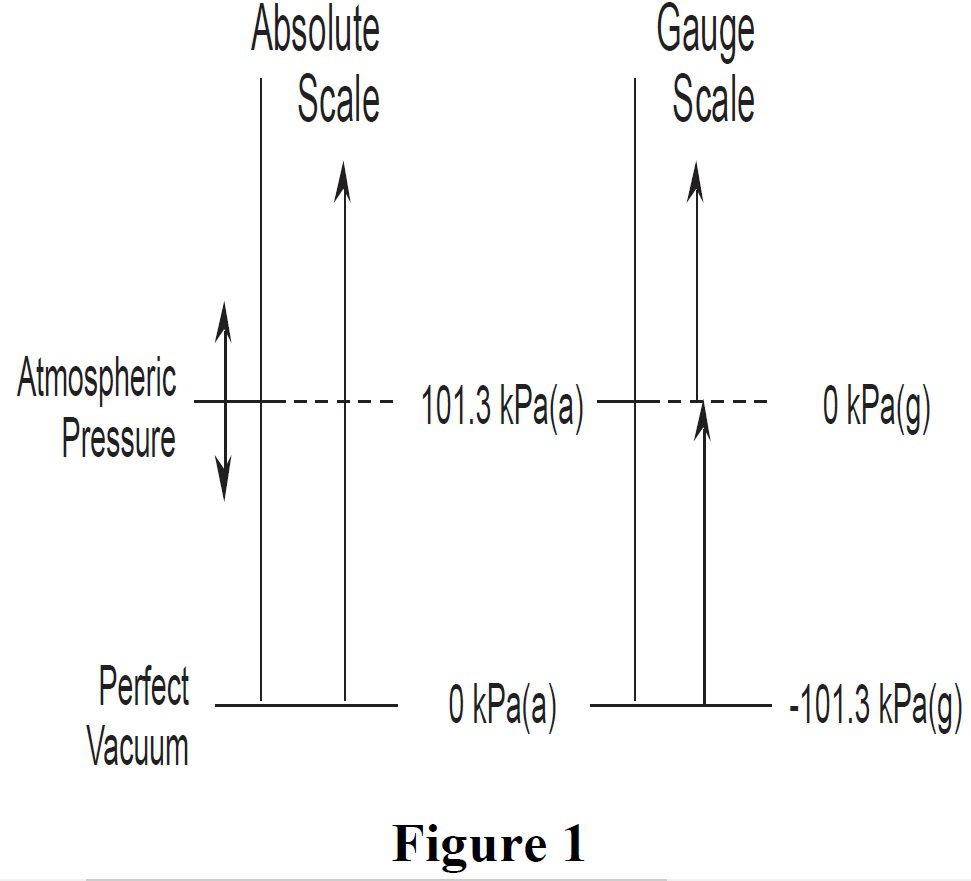

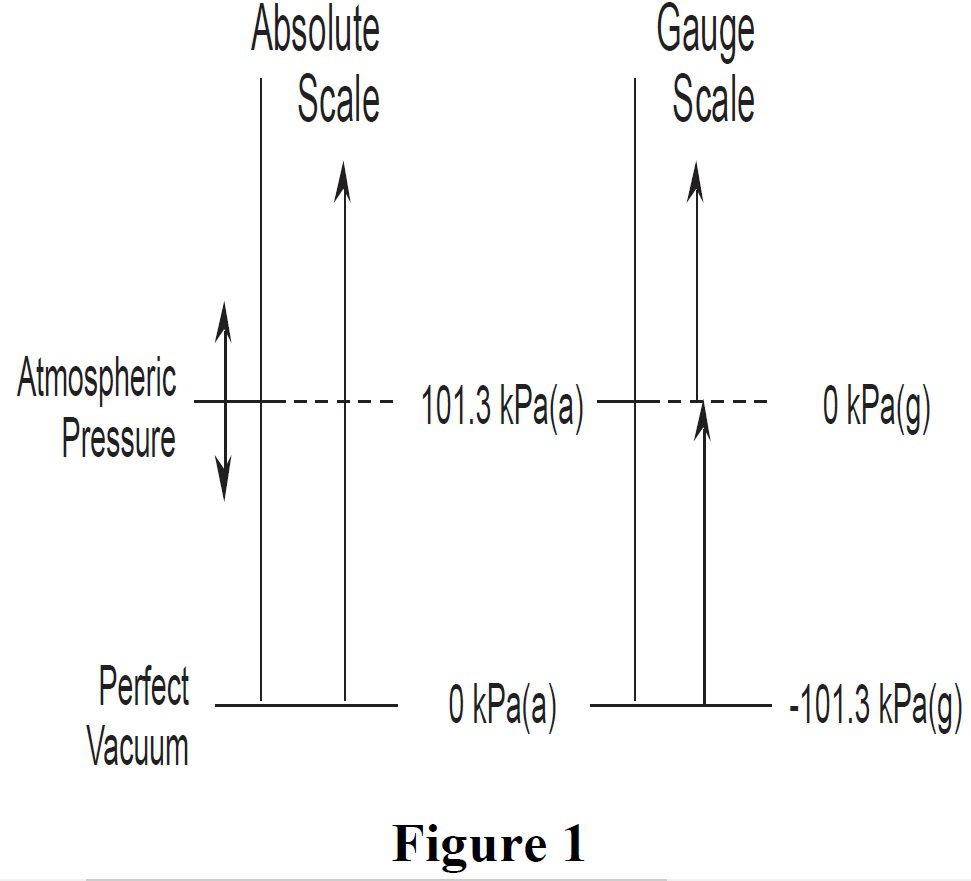

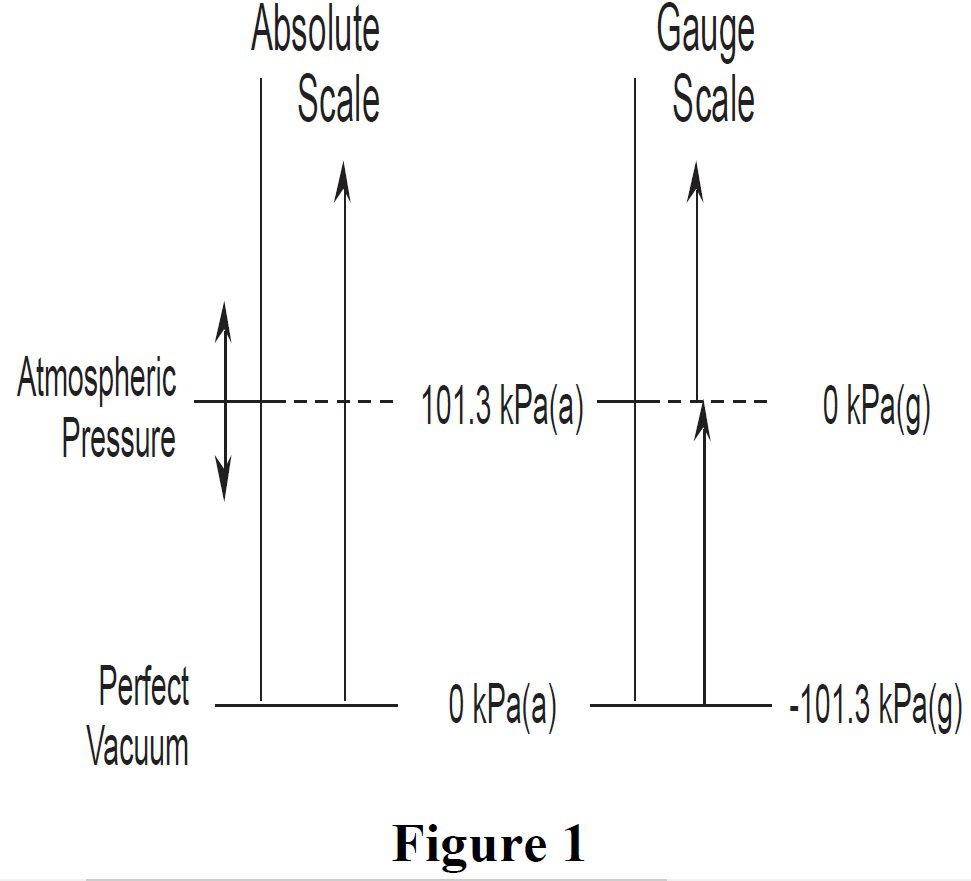

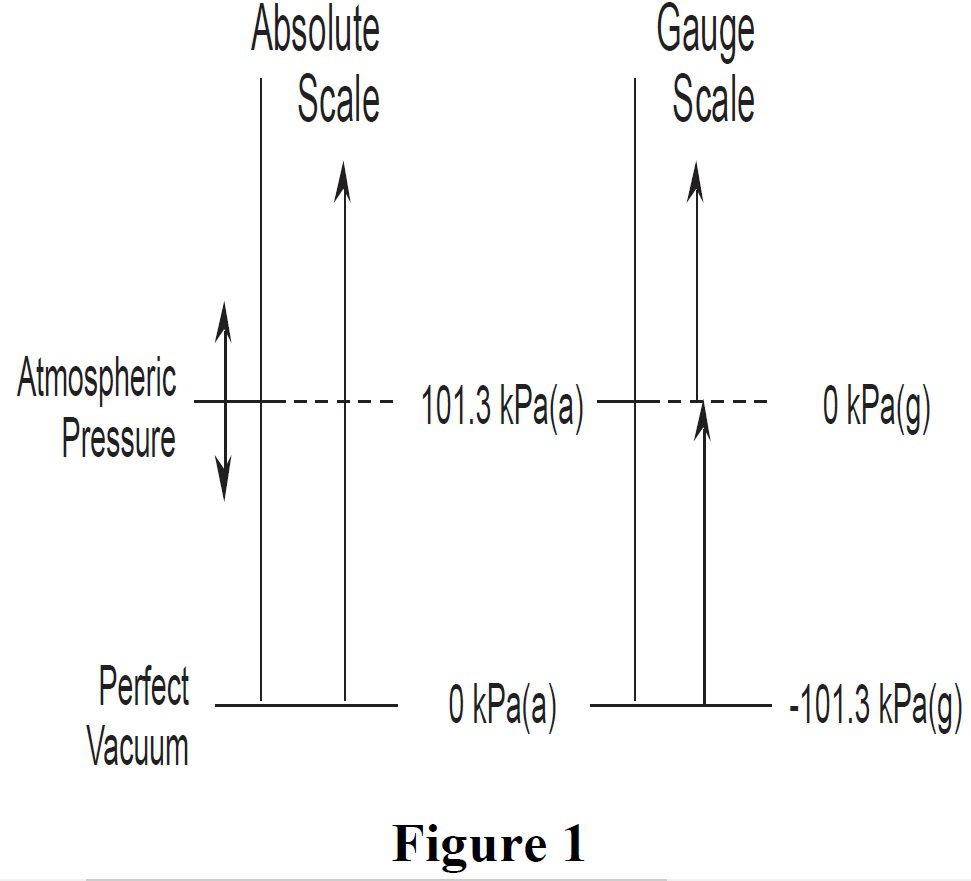

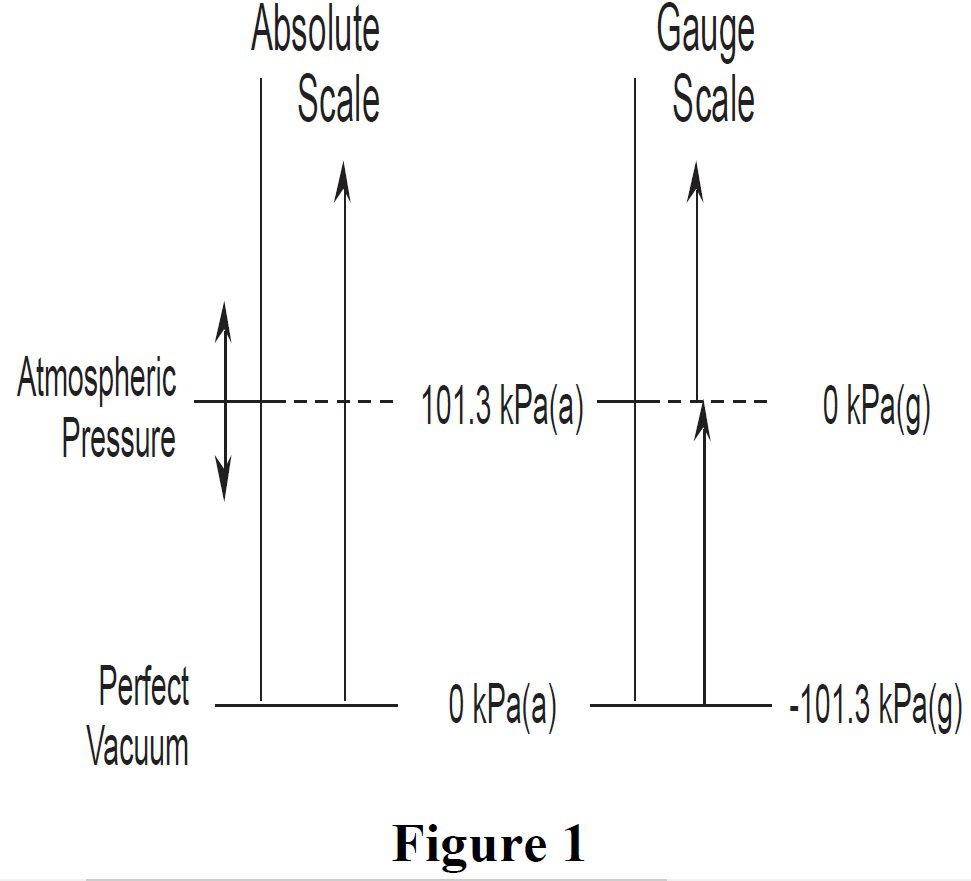

Pressure Scales

Before we go into how pressure is sensed and measured, we have to establish a set of ground rules. Pressure varies depending on altitude above sea level, weather pressure fronts, and other conditions. The measure of pressure is, therefore, relative and pressure measurements are stated as either gauge or absolute. Gauge pressure is the unit we encounter in everyday work (e.g., tire ratings are in gauge pressure).

Gauge Pressure:-

A gauge pressure device will indicate zero pressure when bled down to atmospheric pressure (i.e., gauge pressure is referenced to atmospheric pressure).

Absolute Pressure:–

Absolute pressure includes the effect of atmospheric pressure with gauge pressure. It is denoted by an (a) at the end of the pressure unit [e.g.,kPa (a)]. An absolute pressure indicator would indicate atmospheric pressure when completely vented down to the atmosphere – it would not indicate scale zero.

Absolute Pressure = Gauge Pressure + Atmospheric Pressure

Figure 1 illustrates the relationship between absolute and gauge. Note that the base point for gauge scale is [0 kPa (g)] or standard atmospheric pressure 101.3 kPa (a).

The majority of pressure measurements in a plant are gauge. Absolute measurements tend to be used where pressures are below the atmosphere.

Typically this is around the condenser and vacuum building.

Pressure Transducers

Principle:-

Almost all pressure transducers operate on the basis of elastic deflection – the applied pressure causes some component to deform or deflect.

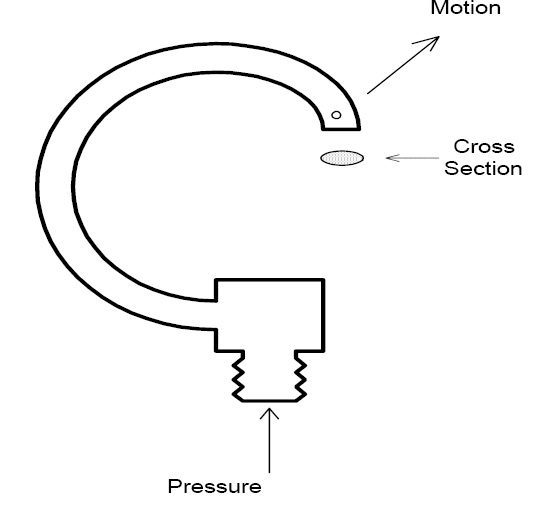

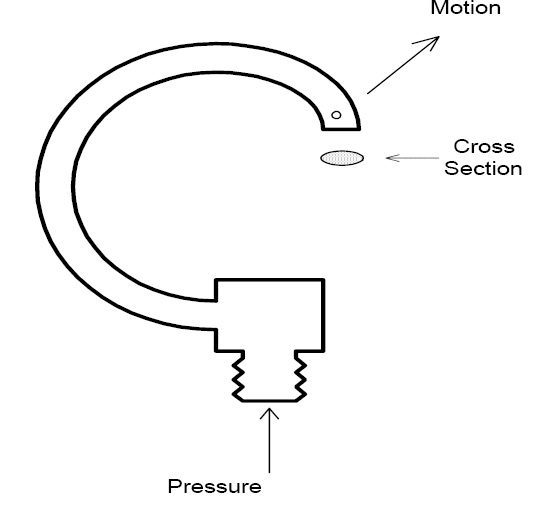

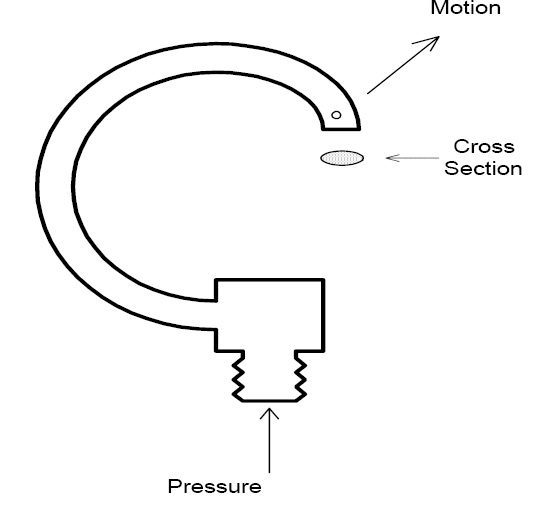

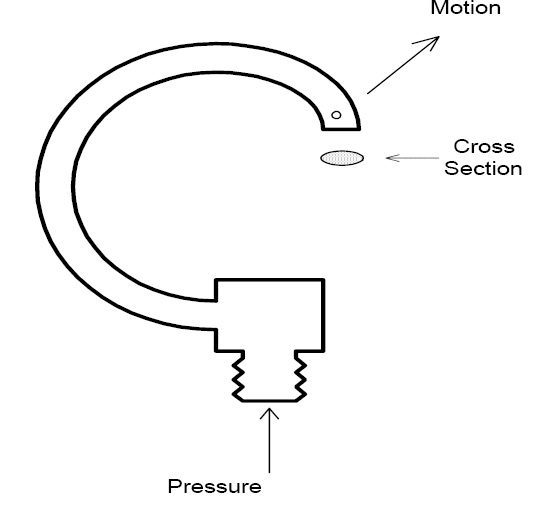

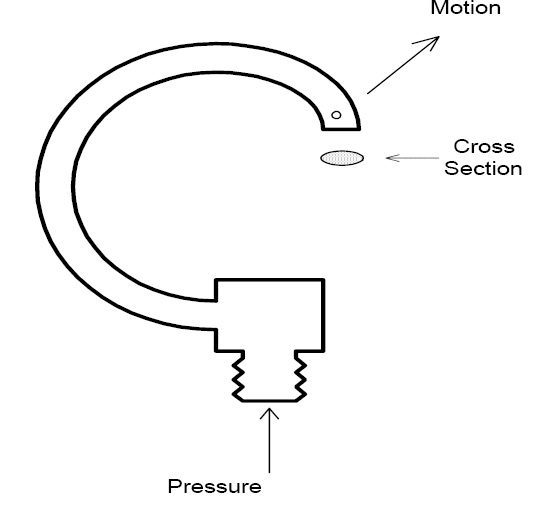

Bourdon Tubes

Bourdon tubes are circular-shaped tubes with oval cross-sections. The pressure of the medium acts on the inside of the tube. The outward pressure on the oval cross-section forces it to become rounded. Because of the curvature of the tube ring, the bourdon tube then bends as indicated in the direction of the arrow.

USAGE:-

Due to their robust construction, bourdon is often used in harsh environments and high pressures, but can also be used for very low pressures. the response time, however, is slower than the bellows or diaphragm

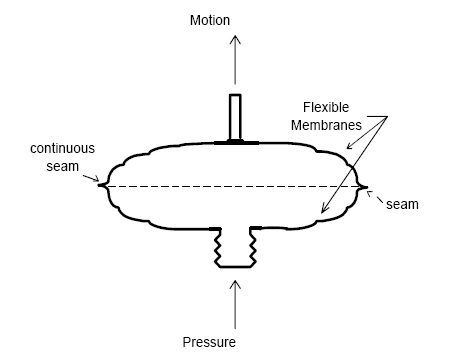

Bellows

Bellows type elements are constructed of tubular membranes that are convoluted around the circumference. The membrane is attached at one end to the source and at the other end to an indicating device or instrument. The bellows element can provide a long range of motion (stroke) in the direction of the arrow when input pressure is applied.

Diaphragms

A diaphragm is a circular-shaped convoluted membrane that is attached to

the pressure fixture around the circumference. The pressure medium is on one side and the indication medium is on the other. The deflection that is created by pressure in the vessel would be in the direction of the arrow indicated.

USAGE:-Diaphragms provide fast-acting and accurate pressure indication. However, the movement or stroke is not as large as the bellows

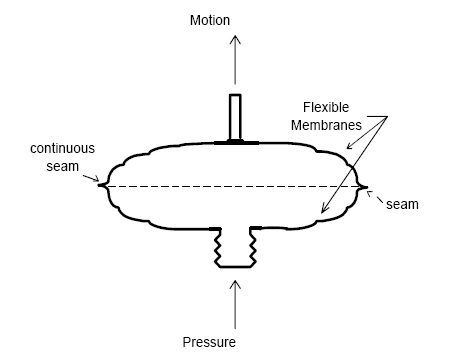

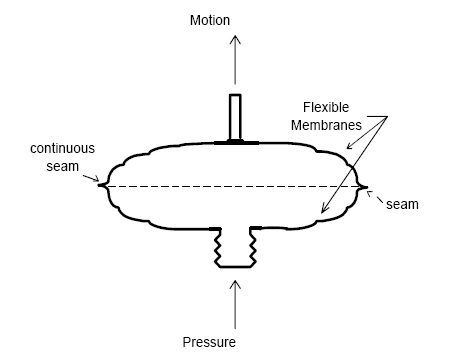

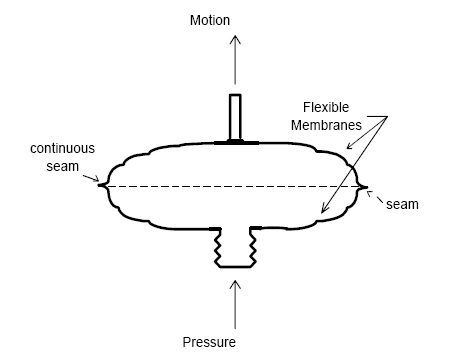

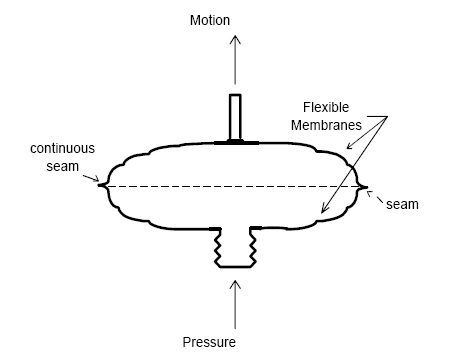

Capsules

The pressure is applied to the inside of the capsule and if it is fixed only at the air inlet it can expand like a balloon. This arrangement is not much different from the diaphragm except that it expands both ways. The capsule consists of two circular shaped, convoluted membranes (usually stainless steel) sealed tight around the circumference. The pressure acts on the inside of the capsule and the generated stroke movement is shown by the direction of the arrow.

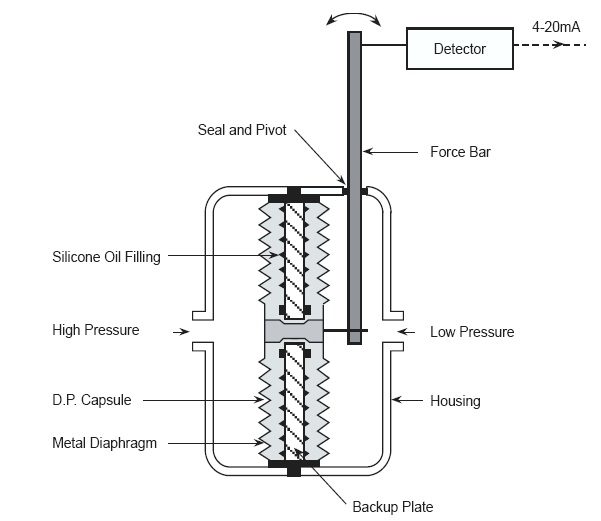

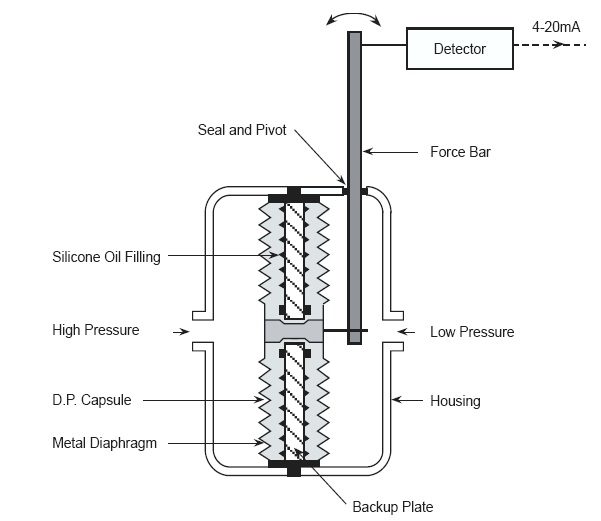

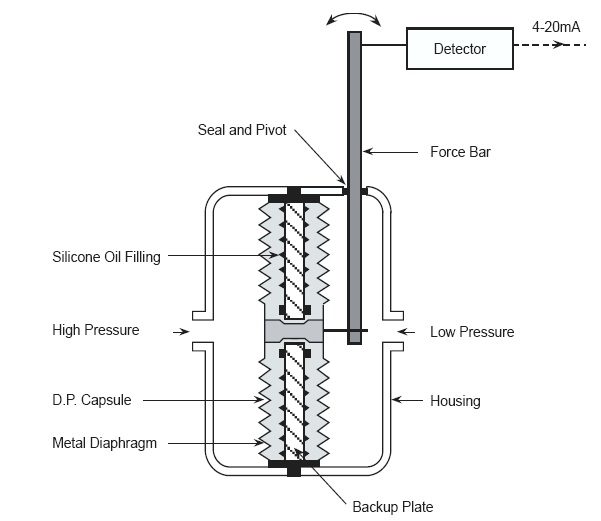

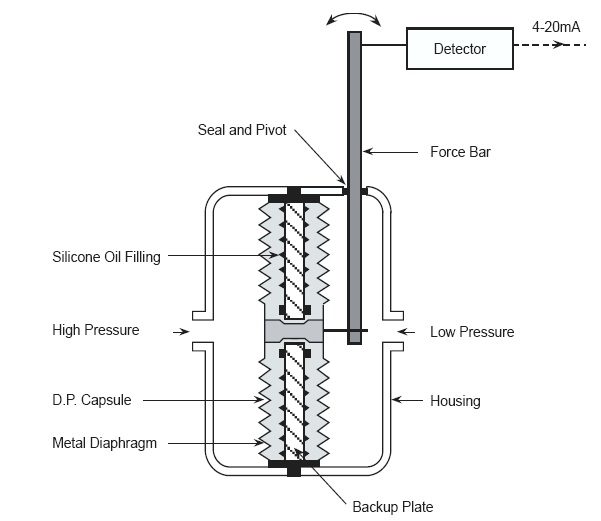

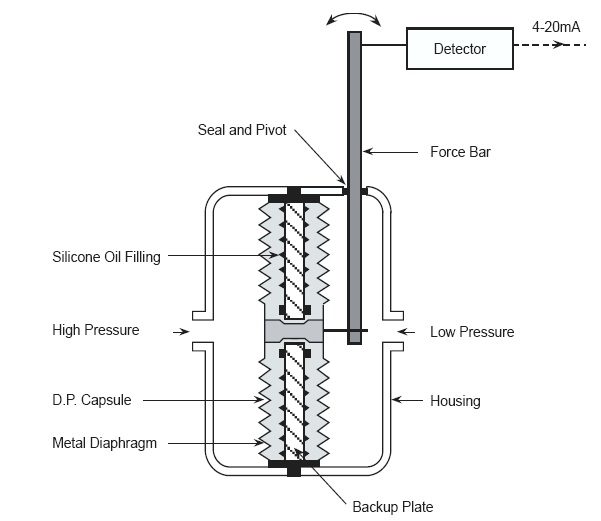

Differential Pressure Transmitters

Most pressure transmitters are built around the pressure capsule concept. They are usually capable of measuring the differential pressure (that is, the difference between a high-pressure input and a low-pressure input) and therefore, are usually called DP transmitters or DP cells. The figure illustrates a typical DP transmitter. A differential pressure Capsule is mounted inside a housing. One end of a force bar is connected to the capsule assembly so that the motion of the capsule can be transmitted to outside the housing. A sealing mechanism is used where the force bar penetrates the housing and also acts as the pivot point for the force bar. Provision is made in the housing for high- pressure fluid to be applied on one side of the capsule and low-pressure fluid on the other. Any difference in pressure will cause the capsule to deflect and create motion in the force bar. The top end of the force bar is then connected to a position detector, which via an electronic system will produce a 4 – 20 ma signal that is proportional to the force bar movement.

DP Transmitter Application

There are following applications:-

1- Level Measurement

2- Differential Pressure Measurement

3- Flow Measurement.

Strain Gauge

A Strain gauge (sometimes referred to as a Strain gauge) is a sensor whose resistance varies with applied force; It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. When external forces are applied to a stationary object, stress and strain are the results. Stress is defined as the object’s internal resisting forces, and strain is defined as the displacement and deformation that occur.

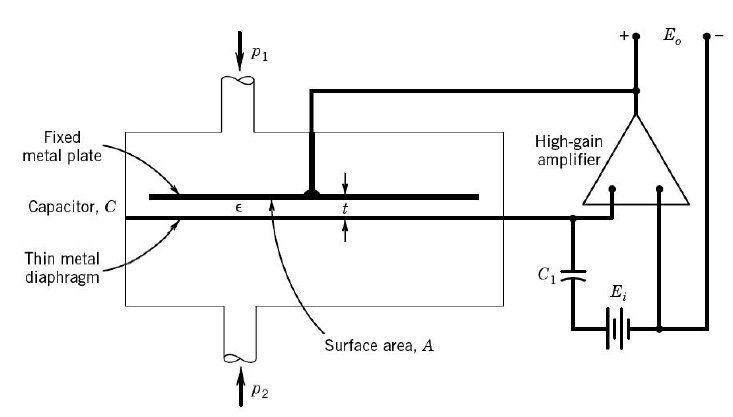

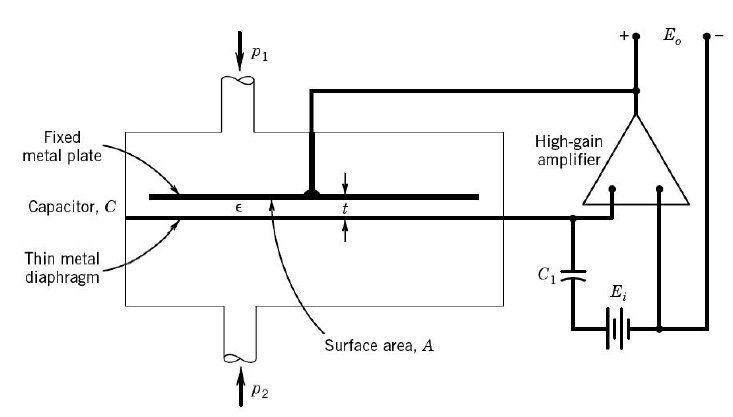

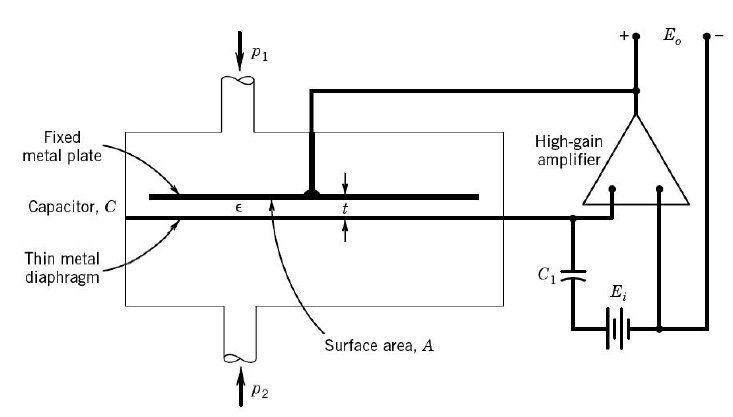

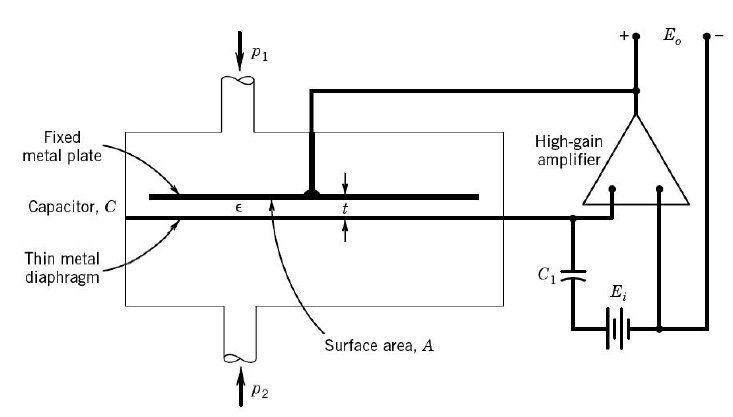

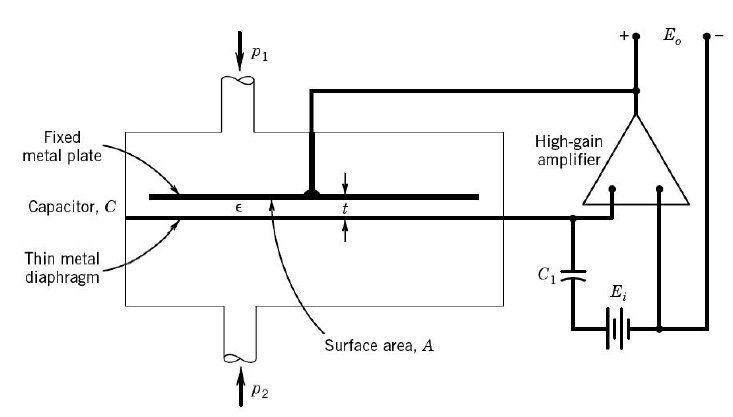

Capacitance Capsule

Similar to the strain gauge, a capacitance cell measures changes in electrical characteristics. As the name implies the capacitance cell measures changes in capacitance. The capacitor is a device that stores an electrical charge. It consists of metal plates separated by an electrical insulator. The metal plates are connected to an external electrical circuit through which

electrical charge can be transferred from one metal plate to the other. The capacitance of a capacitor is a measure of its ability to store charge. The capacitance of a capacitor is directly proportional to the area of the metal plates and inversely proportional to the distance between them. It also depends on the characteristic of the insulating material between them. This characteristic, called permittivity is a measure of how well the insulating material increases the ability of the capacitor to store charge.

C is the capacitance in Farads

A is the area of the plates

D is the distance of the plates

ε is the permittivity of the insulator

By building a DP cell capsule so there are capacitors inside the cell

capsule, differential pressures can be sensed by the changes in capacitance

of the capacitors as the pressure across the cell is varied.