Table of Contents

Solenoid valves are essential components in various industries, including manufacturing, automation, and fluid control systems. These valves are widely used to control the flow of fluids or gases in a precise and efficient manner. Solenoid valves come in different types, each with its unique characteristics and applications. In this article, we will explore the classification of solenoid valves, providing an overview of their types, features, and common applications.

1. Introduction

Solenoid valves are electromechanical devices that use an electromagnetic coil to control the flow of fluids or gases through an orifice. They are widely used in various applications, such as controlling water flow in irrigation systems, pneumatic control in manufacturing processes, and fluid regulation in medical equipment. Solenoid valves offer fast response times, precise control, and reliable operation, making them an integral part of many systems.

2. Direct-Acting Solenoid Valves

Direct-acting solenoid valves are the most common type of solenoid valves. They consist of a solenoid coil, a plunger, and a valve seat. When the coil is energized, it creates a magnetic field that attracts the plunger, allowing the fluid or gas to flow through the valve. Direct-acting solenoid valves can be further classified into two categories: normally closed (NC) and normally open (NO) solenoid valves.

2.1 Normally Closed (NC) Solenoid Valves

In normally closed solenoid valves, the valve remains closed when the coil is not energized. When the coil is energized, it generates a magnetic force that lifts the plunger, opening the valve and allowing the flow of fluid or gas. Once the coil is de-energized, a spring or a pressure difference closes the valve, stopping the flow.

2.2 Normally Open (NO) Solenoid Valves

Contrary to normally closed solenoid valves, normally open solenoid valves are in the open state when the coil is not energized. The coil’s electromagnetic force attracts the plunger when energized, closing the valve and stopping the flow. When the coil is de-energized, a spring or pressure difference reopens the valve, allowing the flow of fluid or gas.

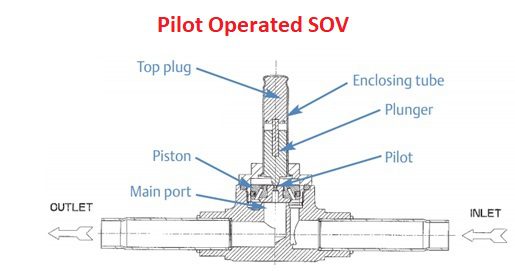

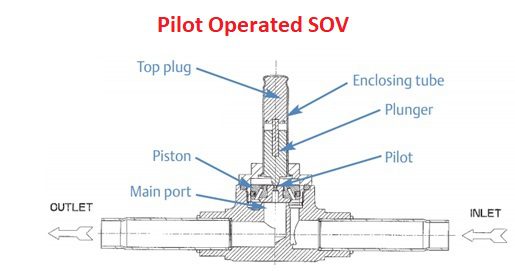

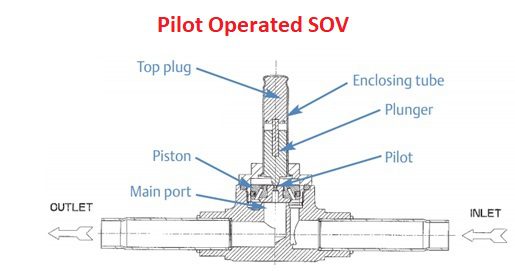

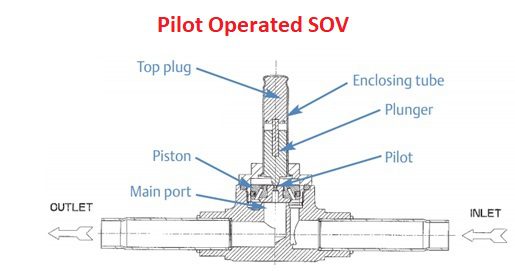

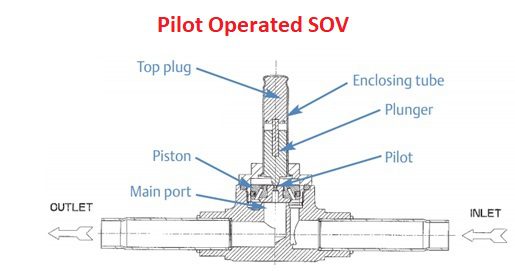

3. Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves are used when higher fluid pressure or flow rates are required. These valves consist of a pilot valve and a main valve. The pilot valve controls the flow of a smaller pilot fluid, which, in turn, operates the main valve. Similar to direct-acting solenoid valves, pilot-operated solenoid valves can be categorized into normally closed (NC) and normally open (NO) types.

3.1 Normally Closed (NC) Pilot-Operated Solenoid Valves

Normally closed pilot-operated solenoid valves require a continuous electrical current to keep the valve open. When the coil is energized, it opens the pilot valve, allowing the pilot fluid to flow and control the main valve’s operation. If the coil is de-energized, the pilot valve closes, and the main valve also closes due to the pressure difference.

3.2 Normally Open (NO) Pilot-Operated Solenoid Valves

Normally open pilot-operated solenoid valves are in the open state without any electrical current. When the coil is energized, it closes the pilot valve, blocking the flow of the pilot fluid. As a result, the pressure on the main valve diaphragm causes it to open, allowing the flow of fluid or gas. De-energizing the coil opens the pilot valve, releasing the pressure and closing the main valve.

4. Two-Way Solenoid Valves

Two-way solenoid valves have two ports: an inlet and an outlet. They can control the flow of fluid or gas in one direction. Two-way solenoid valves are commonly used in applications where on-off control is required.

4.1 Normally Closed (NC) Two-Way Solenoid Valves

In normally closed two-way solenoid valves, the flow is blocked when the coil is de-energized. Energizing the coil opens the valve, allowing the fluid or gas to flow through the inlet and outlet. Once the coil is de-energized, a spring or pressure difference closes the valve, stopping the flow.

4.2 Normally Open (NO) Two-Way Solenoid Valves

Normally open two-way solenoid valves allow the flow of fluid or gas when the coil is de-energized. Energizing the coil closes the valve, blocking the flow. Similar to normally closed valves, a spring or pressure difference can reopen the valve when the coil is de-energized.

5. Three-Way Solenoid Valves

Three-way solenoid valves have three ports: one inlet and two outlets (or vice versa). These valves can control the flow between two different paths. They are commonly used in applications where diversion or selection of fluids or gases is required.

5.1 Three-Way Normally Closed (NC) Solenoid Valves

In three-way normally closed solenoid valves, the flow is blocked between the inlet and one outlet when the coil is de-energized. Energizing the coil opens the valve, allowing the flow between the inlet and the previously blocked outlet. When the coil is de-energized again, the valve closes, stopping the flow.

5.2 Three-Way Normally Open (NO) Solenoid Valves

Three-way normally open solenoid valves allow the flow between the inlet and one outlet when the coil is de-energized. Energizing the coil closes the valve, blocking the flow between the inlet and the previously open outlet. De-energizing the coil again opens the valve, allowing the flow to resume.

6. Four-Way Solenoid Valves

Four-way solenoid valves have four ports: two inlets and two outlets. These valves can control the flow between two different paths, enabling both flow selection and reversal. They are commonly used in applications where directional control or alternate flow paths are required.

6.1 Four-Way Normally Closed (NC) Solenoid Valves

In four-way normally closed solenoid valves, the flow is blocked between the two inlets and two outlets when the coil is de-energized. Energizing the coil opens one inlet and the corresponding outlet, allowing the flow. De-energizing the coil closes the first inlet and outlet while opening the second inlet and outlet, reversing the flow direction.

6.2 Four-Way Normally Open (NO) Solenoid Valves

Four-way normally open solenoid valves allow the flow between the two inlets and two outlets when the coil is de-energized. Energizing the coil closes one inlet and the corresponding outlet, blocking the flow. De-energizing the coil opens the first inlet and outlet while closing the second inlet and outlet, reversing the flow direction.

7. Latching Solenoid Valves

Latching solenoid valves are designed to hold their current position without continuous electrical power. They use permanent magnets or mechanical latches to maintain the open or closed state even after the coil is de-energized. Latching solenoid valves are commonly used in applications where power consumption needs to be minimized or where maintaining the valve position is crucial.

8. Proportional Solenoid Valves

Proportional solenoid valves offer precise control of fluid or gas flow by varying the current through the coil. These valves can adjust the flow rate based on the input signal, providing proportional control and modulation. Proportional solenoid valves find applications in various industries, including HVAC systems, automotive, and process control.

9. Conclusion

Solenoid valves play a vital role in controlling the flow of fluids and gases in different industries and applications. Understanding the classification of solenoid valves, including direct-acting, pilot-operated, two-way, three-way, four-way, latching, and proportional valves, allows for informed decision-making when selecting the most suitable valve for specific requirements. Each type of solenoid valve has its unique characteristics and applications, providing precise and efficient flow control.

Read More About SOV Click Here

10. Frequently Asked Questions

Q1: What is the primary function of solenoid valves?

A1: Solenoid valves are used to control the flow of fluids or gases in various systems and industries.

Q2: Can solenoid valves be used for both liquid and gas applications?

A2: Yes, solenoid valves can be used for controlling the flow of both liquids and gases, depending on their design and specifications.

Q3: What are the advantages of using pilot-operated solenoid valves?

A3: Pilot-operated solenoid valves offer higher pressure and flow capabilities compared to direct-acting solenoid valves, making them suitable for applications with demanding requirements.

Q4: Are solenoid valves suitable for high-pressure applications?

A4: Yes, there are solenoid valves specifically designed to handle high-pressure applications. It is important to choose a solenoid valve that is rated for the desired pressure range.

Q5: How do latching solenoid valves differ from other types?

A5: Latching solenoid valves can maintain their position without continuous electrical power, thanks to the use of permanent magnets or mechanical latches.

Read Also

- What are the pressure sensing elements

- What is Thermometer ? What are the types of Thermometer ?

- What is Thermocouple and its Tpyes

- What is RTD and its Types?

- DP type Level Measurement

- Radar Level Transmitter