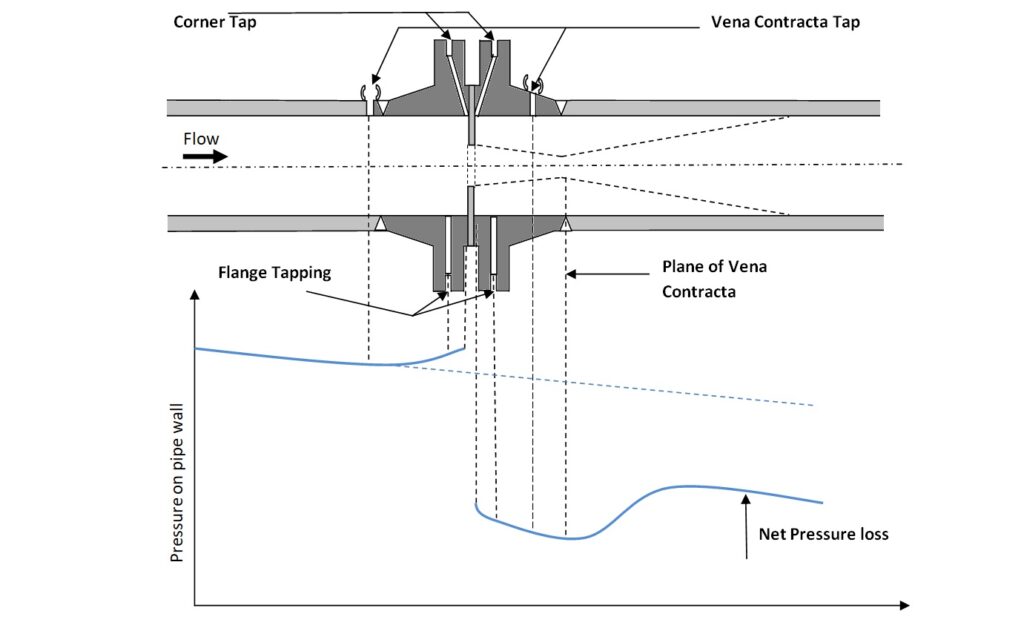

Type of Orifice Tapping Connection :- There are 5 common tape locations for taking D. P. measurements across primary Elements. They are Flange, Corner, Vena contracta, Radius and Pipe.

Flange tapping: These are the predominant type in use and are normally located 1 inch from upstream face of the orifice plate and 1 inch from the downstream face. Flange tapings are not recommended for pipe sizes less than 2 inches since the vena contracta may be less than 1 inch from the orifice plate.

In flange tapping the tapping diameter must be less than both 0.13D and 13mm. In API standard , The tapping diameter must be 9.5mm(3/8”) for 2” and 3” diameter pipe size and 12.7mm(1/2”) for 4” and large pipe size.

The permitted tapping spacing for flange tapping :-

25.4 mm +- 0.5mm for β>0.6 and D<150 mm

25.4 mm+- 1mm in all other cases i.e. β<0.6 and or β <0.6 but 150<D<1000mm

Orifice Tapping: These are normally supplied with -inch tapings in flanges with a minimum of 300-psig rating. These flanges have a minimum thickness of 1.5 inches. Smaller size flanges are normally thicker than 1.5 inches. In some cases where -inch Tapping are used, the flange thickness should be 1-5/8 inches .

Corner Tapping: These are located directly at the faces of the orifice plate. They are in common use in Europe and are particularly useful for pipe size less than 2 inches where the vena contracta may occur inside the dimension of the standard flange tapping. Possible difficulties in using corner tapings are small passages are vulnerable to plugging and Tests have indicated pressure instability in the region of the orifice face.

Care should be taken to avoid measuring the downstream pressure in a highly turbulent area after the vena contracts. This is why the pipe tap (also known as a full-flow tap) standard calls for a downstream tap location eight pipe diameters away from the orifice: the flow gives the stream room to stabilize for more consistent pressure readings.

Wherever the taps are located, it is extremely important that the tap holes are completely flush with the inside wall of the pipe or flange.

Even the smallest recess or burr left from drilling will cause measurement errors, which is why tap holes are best drilled in a controlled manufacturing environment, rather than at the installation site where work is likely non-existent. will be done by experts.

Vena contracta Tapping: These are made at locations, which theoretically take advantage of the highest delta P available at the orifice. The upstream tapping is located one pipe diameter firm the face of orifice while the downstream tapping is located at the vena contracta, the point of minimum pressure caused by the restriction. However, the point of minimum pressure varies with the d/D ratio, there by introducing an error if the plate bore is changed.

Radius Tapping: These are a close approximation of vena contracta tapings, at locations one pipe diameter upstream and 1/2inches pipe diameter downstream from the orifice face.

Pipe Tapping: These or full flow tapings measure the permanent pressure loss across an orifice. The tapings are located 2.5 pipe diameters (2.5 D) up stream (a head of the pressure build up near the orifice face) and 8 pipe diameters downstream-where static pressure has reached its maximum following of vena contacta. There is more likelihood of measurement error when pipe tapings are used, and they required longer runs of straight pipe. However, they are sometimes more economical in that they allow usr of stander flanges (sometimes all ready existing), and they also have higher flow rate capabilities than flange or vena contacta tapings.

Read Also