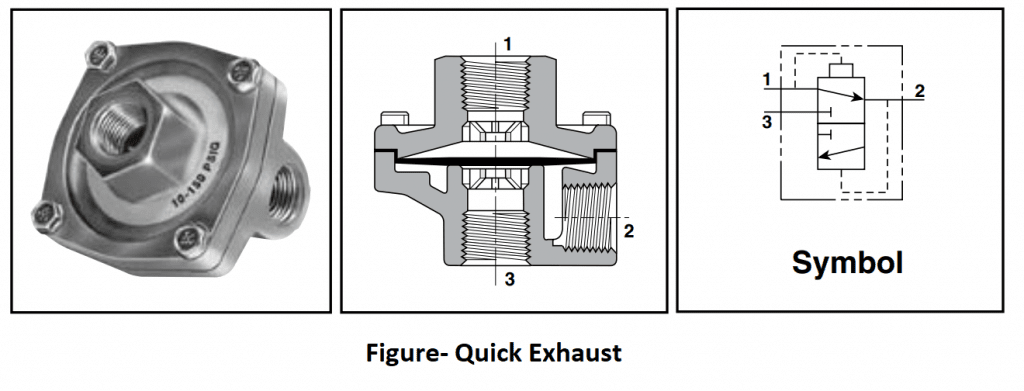

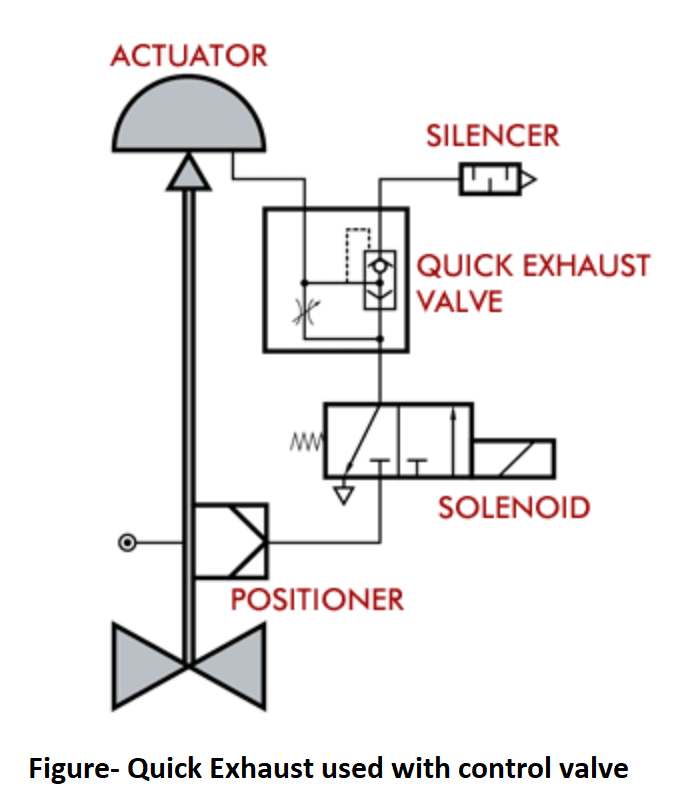

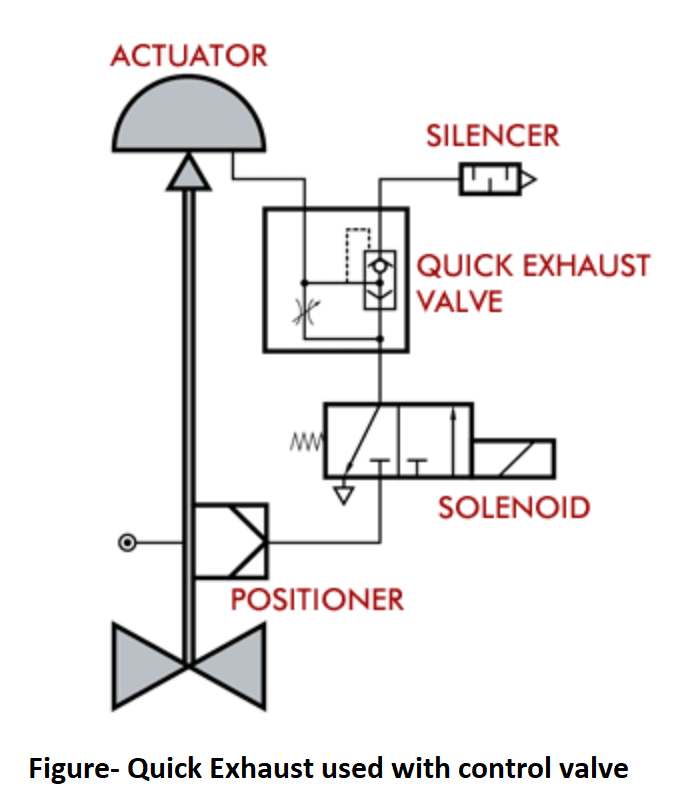

Quick exhaust valve provides rapid exhaust of control air when placed between control valve and actuator. These quick exhausts are required when fast valve closing/ opening is required based on process requirement such as surge valve application. They can also be used as shuttle valves.

A figure showing Quick exhaust with its internal diagram & symbol is given below-

A Shuttle valve determines a single pneumatic output from two separate inputs. If pressure is applied to both ports simultaneously, the valve will select the port with the higher pressure.

A figure showing Shuttle Valve with its internal diagram & symbol is given below-

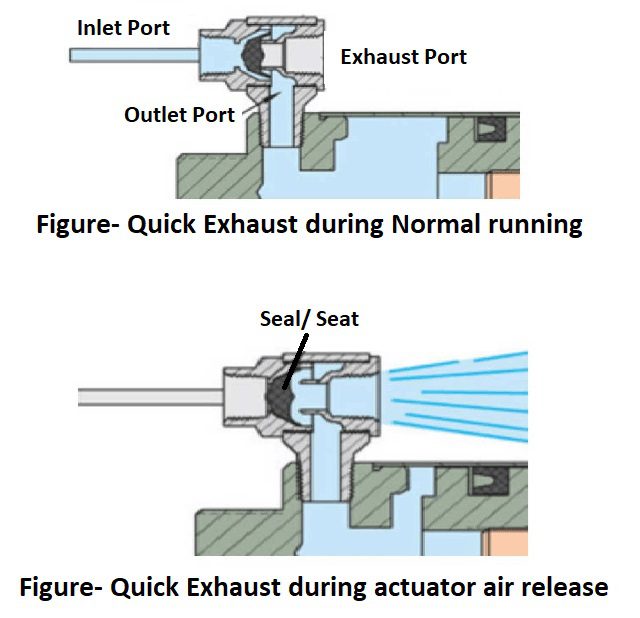

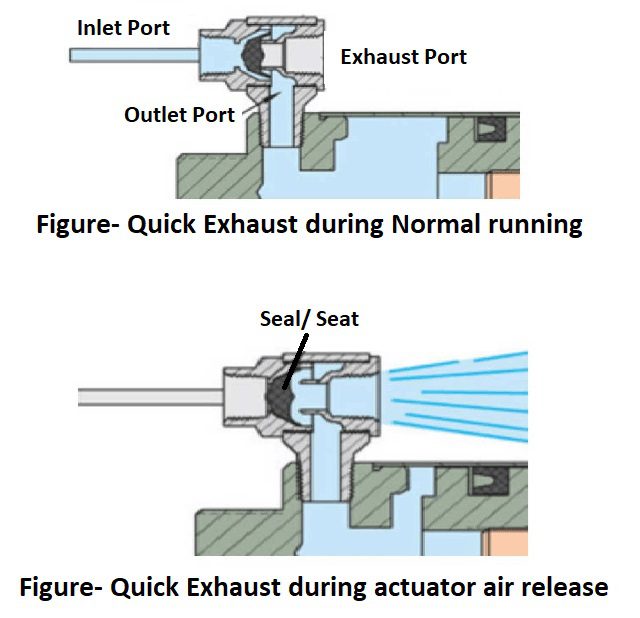

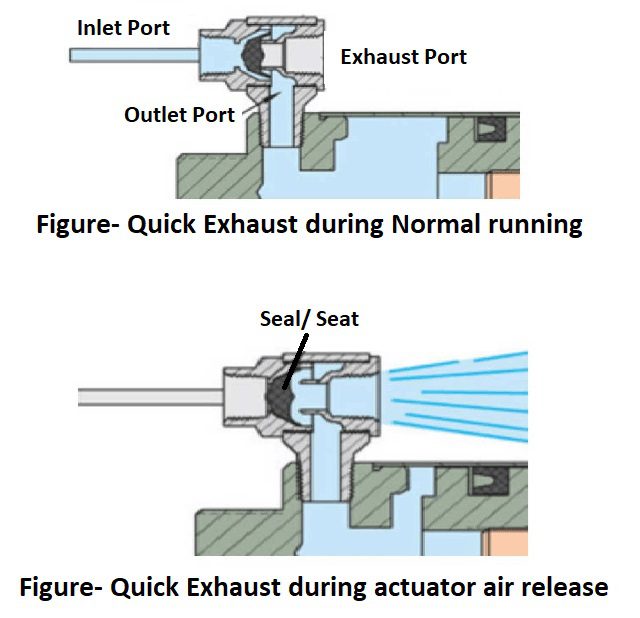

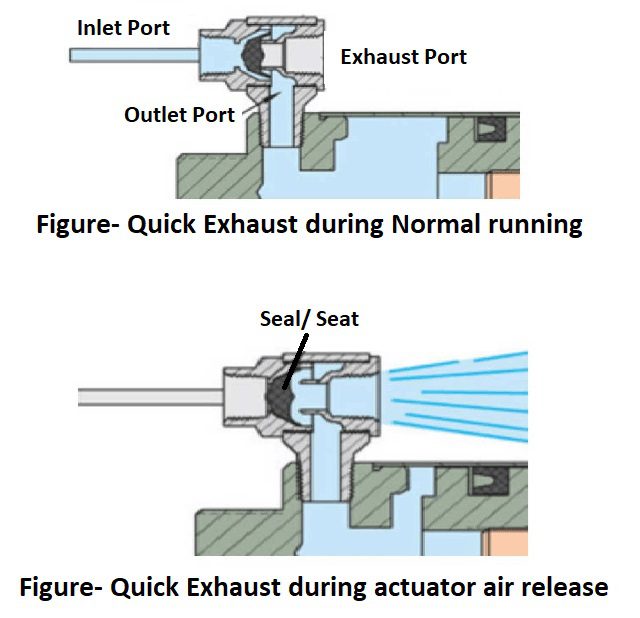

Principle of operation

Quick exhaust valve works by providing a rapid exhaust of controlled air when placed directly on a pneumatic actuator. The seal/ seat inside quick exhaust valve is shaped like a flat wing. When controlled air pressure is sent to the actuator, pressure hits the back side of the seal/ seat and pushes the front side against the exhaust port. Thus seal/ seat allow air to enter into the Actuator. When air fail condition occurs, it is necessary to release air inside actuator as soon as possible for fast action. So here the seal/ seat wing design move back and block off the controlled air inlet port and wide exhaust opening releases actuator chamber air quickly. Thus allows all the exhaust air to immediately dump out through exhaust port.

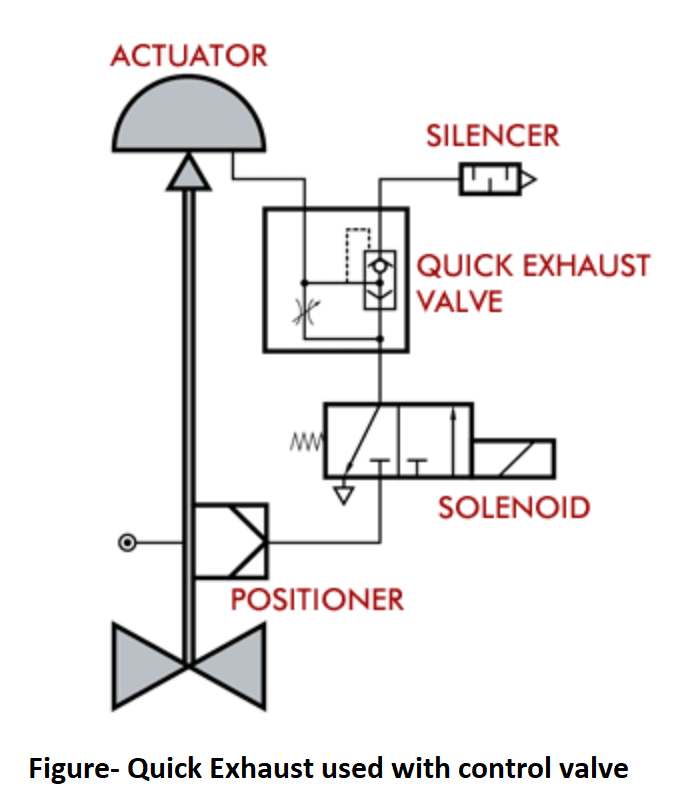

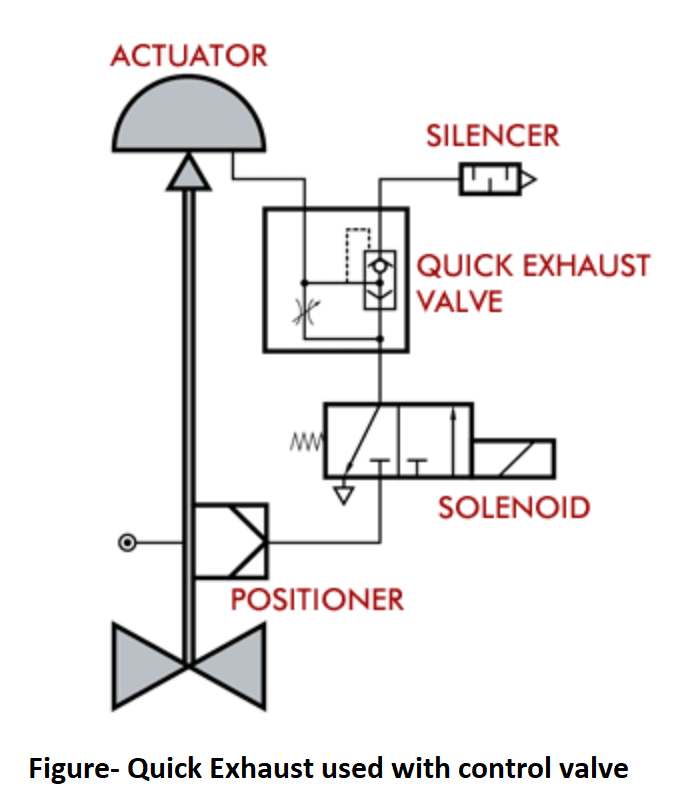

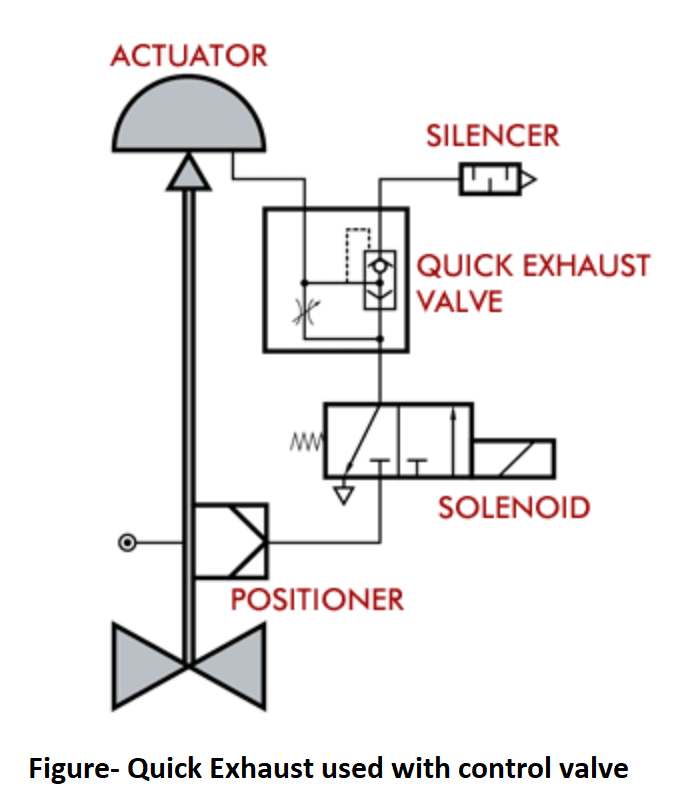

Since air inside actuator is released rapidly so it is recommended to use silencer at exhaust to limit exhaust noise. An application view of quick exhaust with control valve is showing below-

Read Also:-

Valve Position Transmitter

Hazardous Area Classifications