Table of Contents

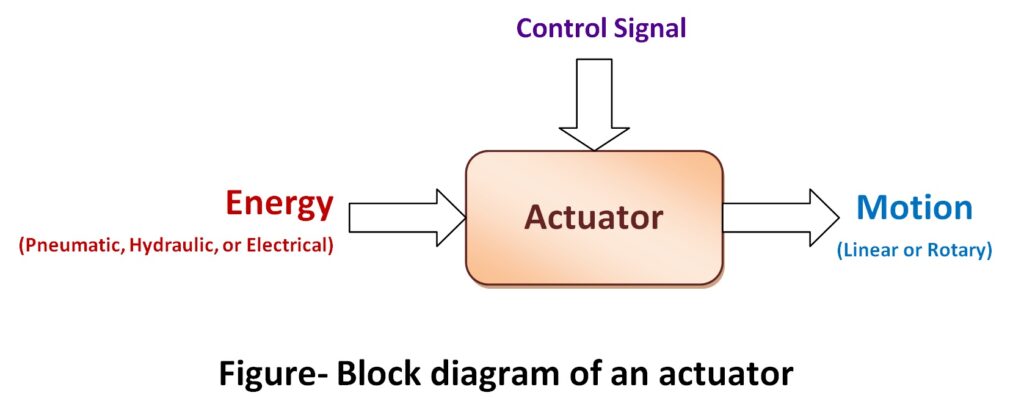

“Actuator is a device which delivers a force or motion by converting source energy according to control signal received. Here source energy can be pneumatic, hydraulic or electric type and motion produced (by itself) can be either linear or rotary.”

OR

“An Actuator is an assembly/ component of a control valve which actuates force and motion to operate a valve based on control signal received. Actuators are termed as mover that requires an energy source which can be pneumatic, hydraulic or electric type. So basically actuators converts pneumatic, hydraulic or electric signal into force and motion to move a valve towards closing or opening.”

A block diagram of simple actuator is shown below-

Examples of actuators

There are wide range of it used in industries and commercial. Some example are given below-

- Pneumatic actuator

- Electro-pneumatic type

- Hydraulic cylinder

- Electro-hydraulic type

- Mechanical type

- Spring actuator

- Electro-mechanical type

- Electric motor type

- Stepper motor

- Servomotor

- Thermal Type

- Shape-memory alloy

- Magnetic Type

- Solenoid

- Piezoelectric type

- Screw jack

- Electro-active polymer

- Shape-memory alloy

- Thermal bimorph

- Comb drive

- Digital micro-mirror device, etc…

Actuator Valve

An actuator valve consists of actuator along with valve body which moves valve in response of control signal. Valve actuator is basically a valve opening and closing mechanism. Manually operated valves require manual interference to adjust accordingly using a direct or geared mechanism attached to the valve stem. Electric-powered type allow a valve to be adjusted remotely, or allow rapid operation of larger valves, using pneumatic air pressure, hydraulic pressure, or electricity. Power-operated valve actuators may be the last element of an automatic control loop that automatically controls some flow, pressure, level, or other process. They may only be for opening and closing valves, or may allow an intermediate position; some valve actuators include switches or other ways to remotely indicate valve position.

Actuators can be found in all types of process plants that are used for the automation of industrial valves. They are used in waste water treatment plants, power plants, refineries, mining and nuclear processes, food factories, and pipelines etc. They play a major role in automating process control. Automatic valves vary in both design and dimensions. The diameter of valves ranges from one-tenth inch to several feet.

A simple design of valve actuator (Pneumatic type) is shown as follows-

An electro-pneumatic actuator valve is shown below-

Actuator Working and function

To understand the working of an actuator, a diagram is shown below-

Actuator receives a source of energy and uses it to produce force or torque to move something (like valve) according to the control signal applied on it. In other words, the it converts a source of energy into a physical or mechanical motion. To determine their working, there are following functional elements used for it-

- Energy source

- Power convertor

- controller

- Actuator Assembly

- Mechanical Load

Energy source-

Energy source provides the energy input that is necessary to drive the actuator. In industrial applications, there are several typical sources of energy used as mentioned below-

- Electrical Energy-Here actuator uses some form of electric energy to operate.

- Hydraulic Energy- Here it uses a variety of fluids (such as oil) to pump and producing fluid pressure to move.

- Pneumatic Energy- Here it uses compressed air to operate valves.

Power convertor and actautor-

The role of the power converter is to provide proportional power in accordance with the control signal given by the controller.

Actuator Assembly-

Actuator assembly basically consists of mechanical parts and components which convert power output from converter into force, torque or motion to drive the load.

Controller-

In industrial application, there are various parameters and process variables which are used to monitor and control the process. These variables are measured using sensor and transducers and compared with desired set point. Thus an error signal is produced which is fed to the controller to produce a control signal to gain desired value of process variable. This control signal is fed to the actuator to power converter to move it.

Mechanical Load-

Mechanical Loads are usually final control elements which are directly involved in a system or process to control physical parameters. Mechanical loads refer to mechanical system that is being driven by the actuator.

Application of actuator

They are an essential part of day-to-day life which is continuously improving automation in the workplace. The simple yet effective machineries allow operators to transform manual functions into automated ones. The wide range of actuators is available to produce must-have devices in equipment in various industries. Some of real world applications are given below-

- For valve operations in process industries

- In material handling

- In robotics

- In food and beverage manufacturing process

- In automobile industries

- In Aerospace industries

- In medical equipment

- In agricultural machinery

- In solar panel operation and control direction

- In cutting, welding and other mechanical equipment

- In other non-industrial applications, etc.

Read Also:-

“Internet of things (IoT)” – Wikipedia link