Table of Contents

What is Proximity Switch?

Proximity switch is a device which detects an object without making physical contact. Proximity switches are use in various devices, from the basic household applications to large scale applications. In Proximity switches we use Proximity sensor. Proximity sensors have a vast range of applications

How Does It Work?

The basic functionality of the proximity sensors is the detection of the objects. The detection of material or an object by the proximity results in an initiation of a specific action. The action initiated upon detection is pre-defined. The detection of the object with the help of proximity sensor is without any physical contact of the sensor with the object. A number of sensing techniques are utilized in the proximity sensor for its operation.

Types of Proximity Switch:

According with the non contact object detection method, there are five types of proximity Switch. They are,

- Inductive Proximity Switch.

- Photoelectric or Optical Proximity Switch.

- Capacitive Proximity Switch.

- Magnetic Proximity Switch.

- Ultrasonic proximity Switch.

1. Inductive Proximity Switch:

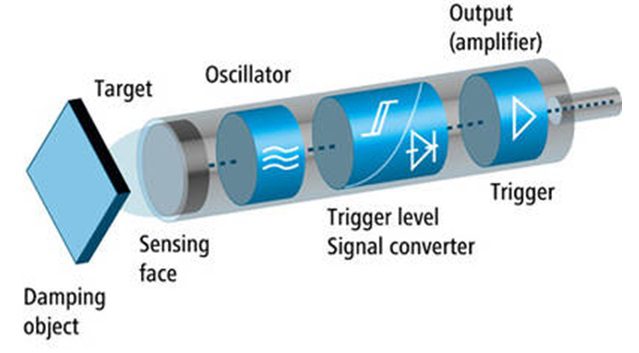

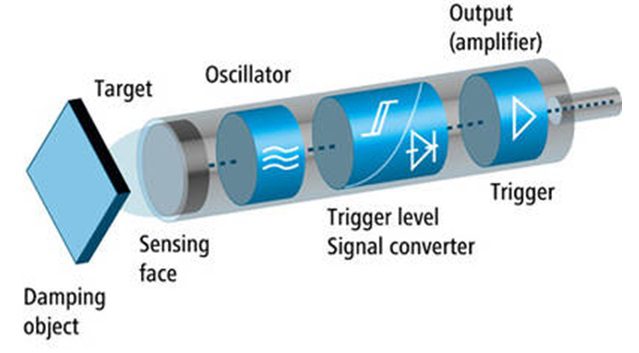

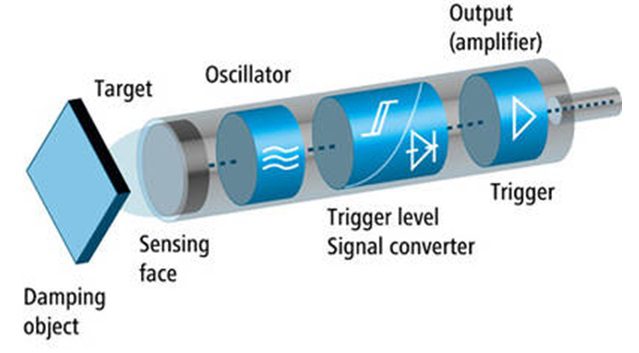

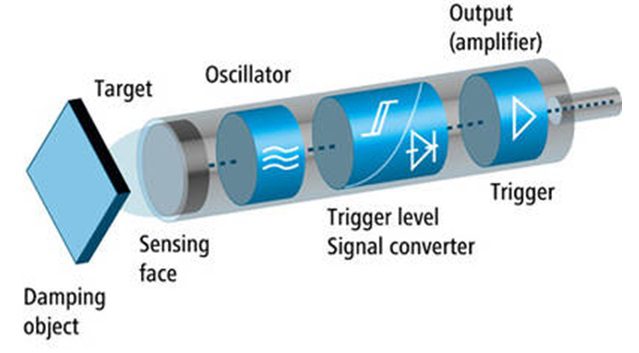

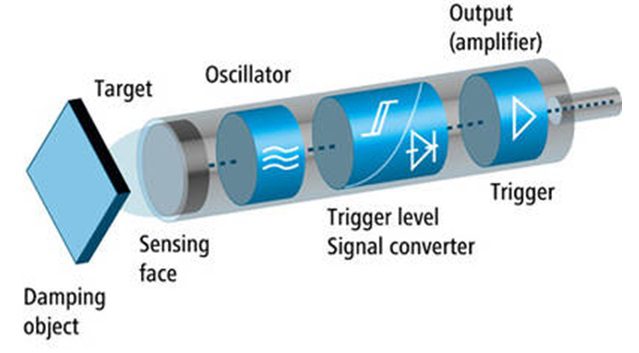

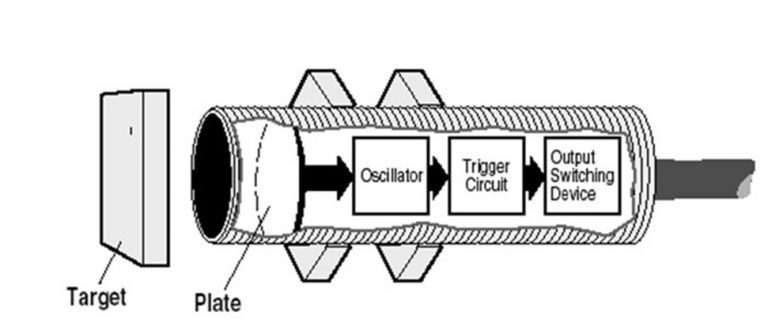

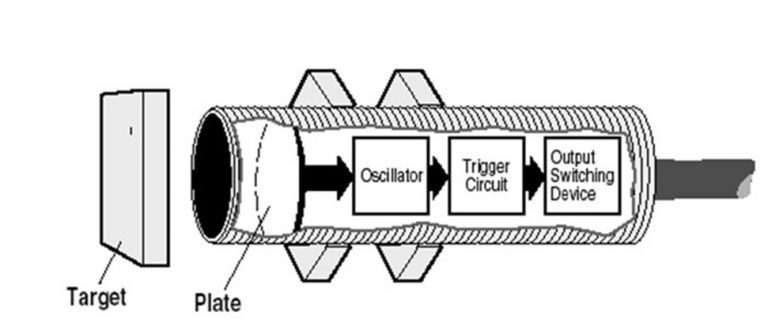

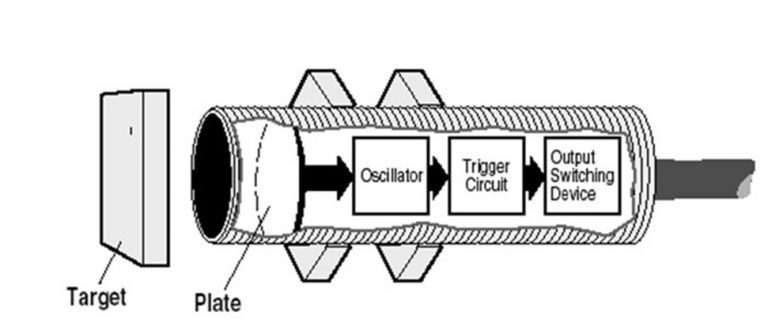

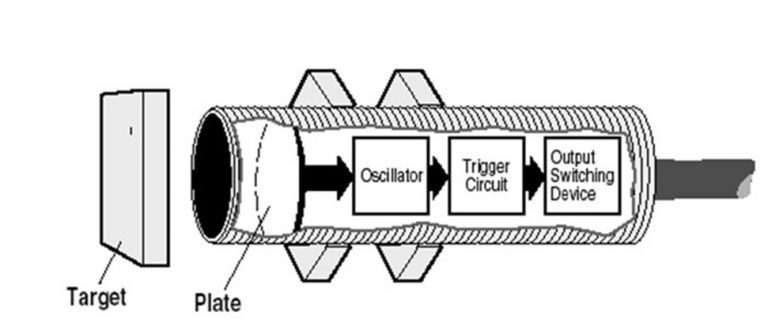

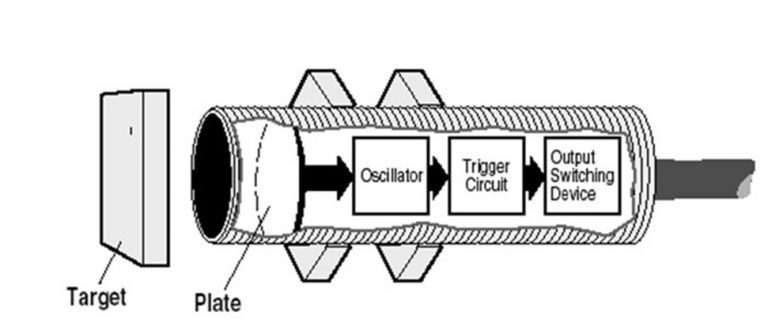

The inductive proximity switch detects the metallic object which is present next to their active side. This sensor operates under the electrical principal of inductance where a fluctuating current induces an electromotive force(EMF) in a target object. They consist of four major components: a ferrite core with coils, an oscillator, a Schmitt trigger, and an output amplifier.

Working Principle: The oscillator creates a symmetrical, oscillating magnetic field that radiates from the ferrite core and coil array at the sensing face. When a ferrous target enters this magnetic field, small independent electrical currents (eddy currents) which are induced on the metal’s surface. An inductive proximity sensor has the frequency range from 10 to 20 Hz in ac, or 500 Hz to 5 kHz in dc. Because of magnetic field limitations, inductive sensors have a relatively narrow sensing range like from fractions of millimetres to 60 mm on an average.

Due to this, load will be caused on the sensor that decreases the electromagnetic field amplitude. If the metal object moves towards the proximity sensor, the eddy current will increase accordingly. Thus, the load on the oscillator will increase, which decreases the field amplitude.

The schmitt trigger block monitors the amplitude of the oscillator and at particular level (predetermined level) the trigger circuit switches on or off the sensor. If the metal object or target is moved away from the proximity sensor, then the amplitude of the oscillator will increase.

The above image shows the waveform of the inductive proximity sensor oscillator in the presence of the target and in the absence of the target.

Nowadays, inductive proximity sensors are available with different operating voltages. These inductive proximity sensors are available in AC, DC, and AC/DC modes (universal modes). The operating range of the proximity sensor circuits is from 10V to 320V DC and 20V to 265V AC

2. Photoelectric or Optical Proximity Switch:

Photoelectric switch are able to detect both metallic and non-metallic targets. They uses in many applications like in mobile phones and for level sensing. In the phone, the sensor is used to deactivate the touch screen as the user brings the device closer to the face.

The main components of this sensor are emitter, detector and associated electronics. Emitter (Light Emitting Diode, laser diode) sends a beam of light. The detector (photo diode or phototransistor) detects emitted light. An associated electronics required to amplify the detected signal.

Working Principle:-

There are three main sensing methods of the photoelectric proximity sensor.

(I)Through beam method

(II)Retro-reflective method

(III)Diffuse or Reflective method

(I) Through beam method:

In this type of method, an emitter sends out a beam of light directly in the line-of-sight of the emitter to a receiver. When an object breaks this beam of light, it detects as a presence. This type of setup requires two components they are an emitter and a separate detector, which makes it a bit more complex to install and wire. However, the advantage is that it’s the most accurate of the sensing methods with the longest sensing range.

New laser diode emitter models can transmit a well-collimated beam 60 m for increased accuracy and detection. At these distances, some through-beam laser sensors are capable of detecting an object the size of a fly, at close range, that becomes 0.01 mm. One ability unique to through beam photoelectric sensors is effective sensing in the presence of thick airborne contaminants.

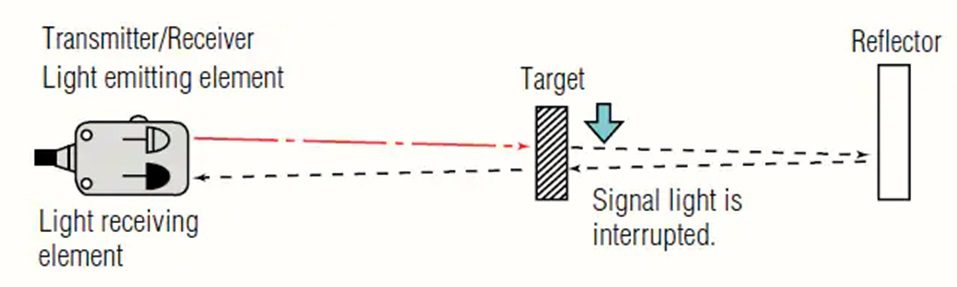

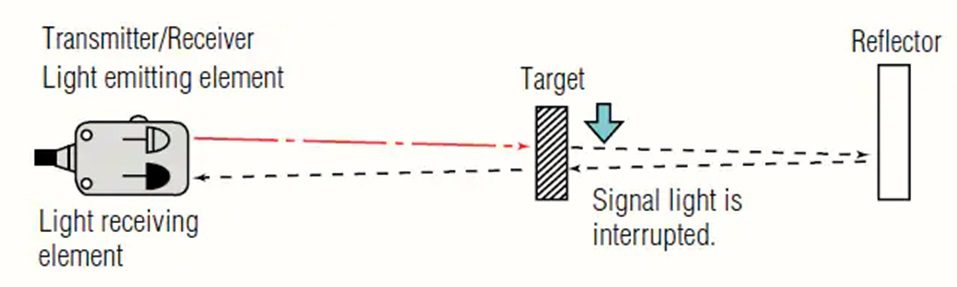

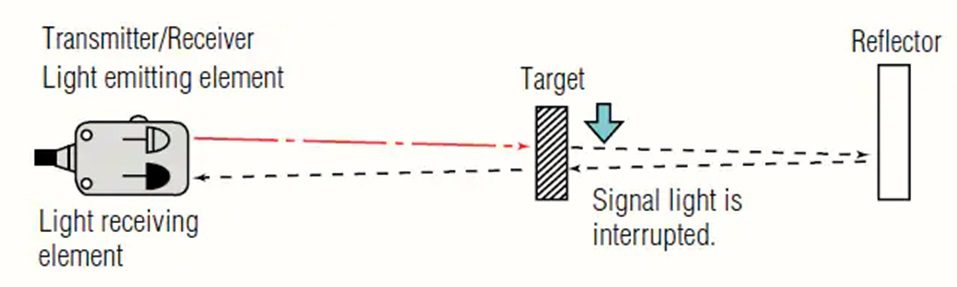

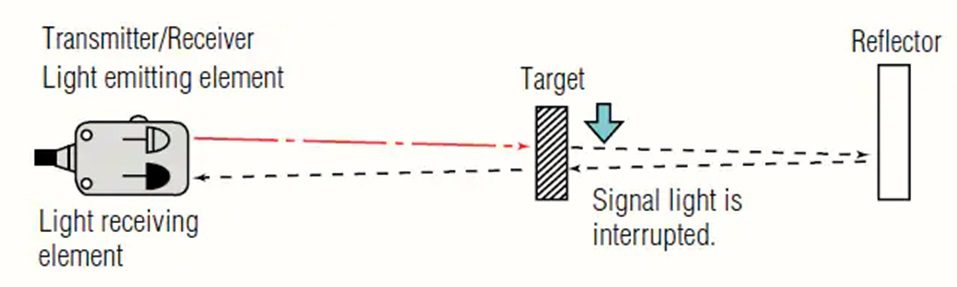

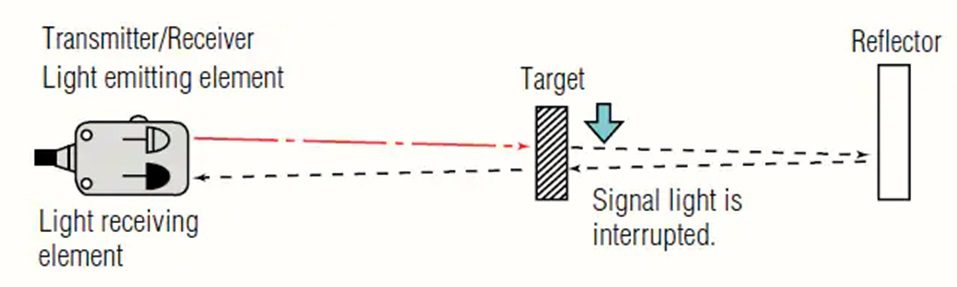

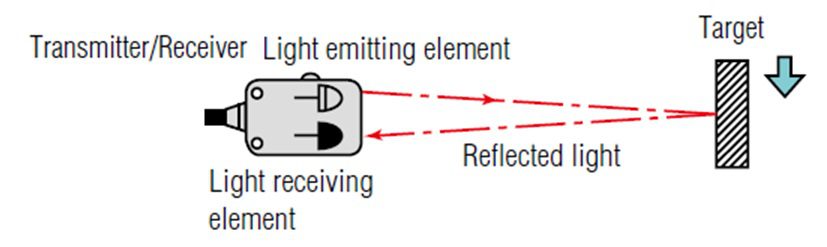

(II) Retro-reflective method:

In this method, detection occurs when the light path breaks or disturbs. Both the light emitting and light receiving elements are in same housing. The light from the emitting element hits the reflector and returns to the light receiving element. When a target is present, the light gets interrupt.

One reason for using a retro-reflective sensor over a through beam sensor is for the convenience of one wiring location, the opposite side only requires reflector mounting.

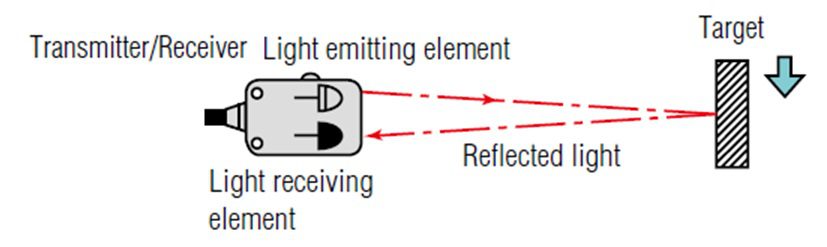

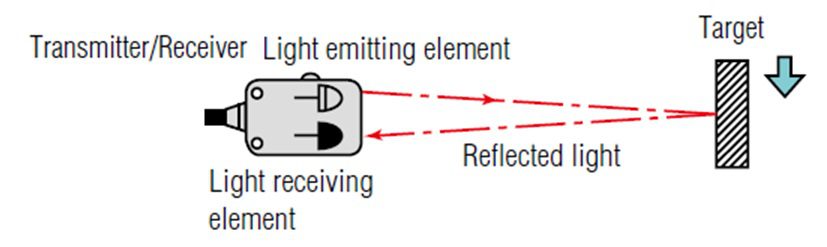

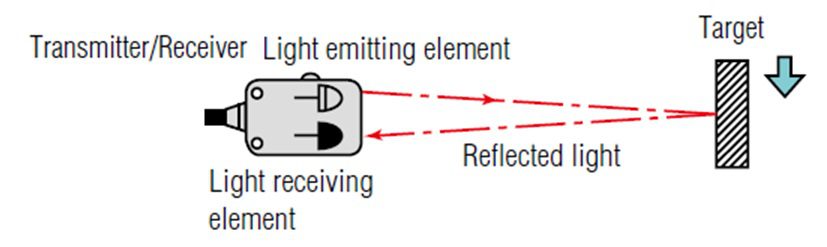

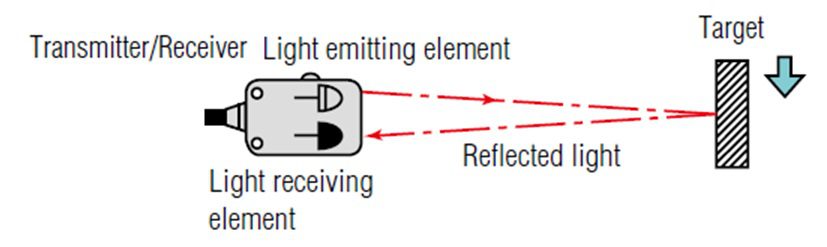

(III) Diffuse or Reflective method:

As in retro-reflective sensors, emitters, and receivers located in the same housing assembly. In this diffusion method, both the light-emitting and light-receiving elements fix in a single housing. The sensor receives the light reflected from the target.

Diffuse photoelectric sensors are similar in some respects to reflective sensors. This is because like reflective sensors they emit a light beam in the direction of the object to be detected. However, instead of a reflector used to bounce back the light to a detector, the object to be sensed functions as the reflector, bouncing back some of the light to be detected and register a presence of object.

Mostly, the diffuse sensors use in public washroom sinks, where they control automatic faucets. Hands placed under the spray head act as reflector, triggering the opening of a water valve. Diffuse sensors are somewhat colour dependent, certain versions are suitable for distinguishing dark and light targets in applications that require sorting or quality control by contrast.

3. Capacitive Proximity Switch:

Capacitive Proximity Switches Sensors detect changes in the capacitance between the sensing object and the Sensor. The amount of capacitance varies depending on the size and distance of the sensing object. An ordinary Capacitive Proximity Sensor is similar to a capacitor with two parallel plates, where the capacity of the two plates detected. One of the plates is the object being measured (with an imaginary ground), and the other is the Sensor’s sensing surface. It detects the changes

in the capacity generated between these two poles. The detection of the object depends on their dielectric constant, but they include resin and water in addition to metals. A typical sensing range for capacitive proximity sensors is from a few millimetres up to about 1 inch. (or 25 mm), and some sensors have an extended range up to 2 inch

Working Principle: The capacitive proximity switch consist a high-frequency oscillator along with a sensing surface formed by two metal electrodes. When an object comes near the sensing surface, it enters into the electrostatic field of the electrodes and changes the capacitance of the oscillator.

As a result, the oscillator circuit starts oscillating and changes the output state of the sensor when it reaches certain amplitude. As the object moves away from the sensor, the oscillator’s amplitude decreases, switching the sensor back to its initial state.

4. Magnetic Proximity Switch

Magnetic sensors are actuated by the presence of a permanent magnet. These can detect magnetic field even through ferromagnetic and non- ferromagnetic materials, it only depends on the power of permanent magnet. Furthermore, these magnetic proximity switches are extensively used for liquid level detection, monitoring of final position, stroke limitation in hydraulic cylinders etc.

Working Principle: There are several operating principles used including reed switches, GMR inductive, variable reluctance, magneto resistive or Hall Effect sensors.

Variable reluctance: Proximity sensors comprise of a permanent magnet and a pick up coil. A VR sensor uses as a simple proximity sensor can determine the position of a mechanical link in a piece of industrial equipment.

A Crankshaft position sensor (in an automobile engine) uses to provide the angular position of the crankshaft to the Engine control unit. The Engine control unit can then calculate engine speed (angular velocity).

A pickup uses in an electric guitar or in other musical instrument detect vibrations of the metallic “strings”.

Magneto-resistive: Proximity sensors measure the magneto-resistive effect or the impact of the resistivity of a ferromagnetic material in the presence of a magnetic field.

Magneto-resistance is the tendency of a material to change the value of its electrical resistance in an externally applied magnetic field.

1.- Reed Switches:

Reed switches are magnetically actuated switches. They typically manufacture with two ferromagnetic reeds (contact blades), which seal powered in a glass capsule. In which consists of two low reluctance ferromagnetic reeds enclosed in glass bulbs containing inert gas.

A magnetic field from an electromagnet or a permanent magnet will cause the reeds to attract each other to establish an electrical circuit. An example of a reed switch application is to detect the opening of a door, when used as a proximity switch for a security alarm.

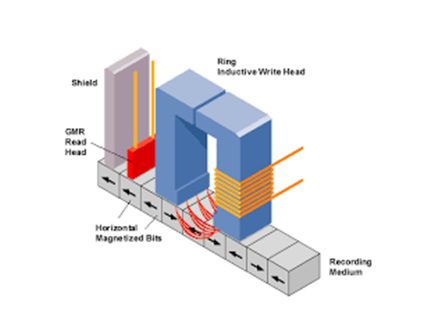

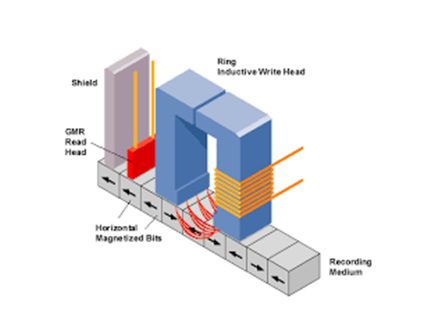

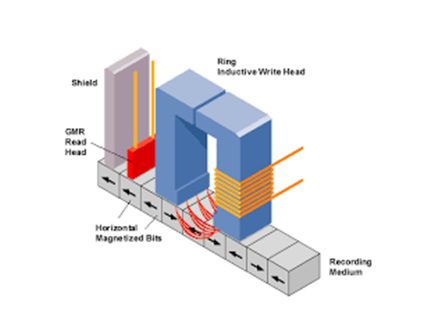

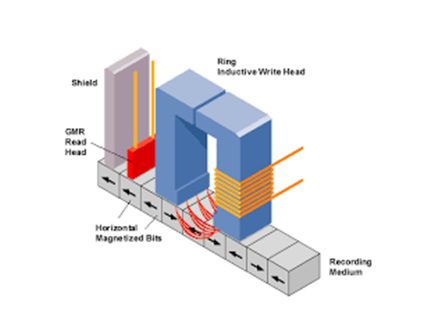

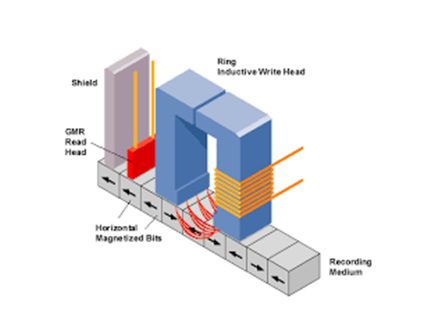

2.– Giant Magneto-Resistive Effect:

Magnetic sensors use GMR (Giant Magneto-Resistive Effect) technology.The measuring cell consists of resistors with several extremely fine, ferromagnetic and non-magnetic layers.

Two of these GMR resistors use to form a conventional Wheatstone bridge circuit which produces a large signal proportional to the magnetic field when a magnetic field is present. A threshold value defines and an output signal switches via a comparator.

The main application of GMR is magnetic field sensors, which use to read data in hard disk drives, biosensors, microelectromechanical systems (MEMS) and other devices. GMR multi layer structures also use in magneto-resistive random-access memory (MRAM) as cells that store one bit of information.

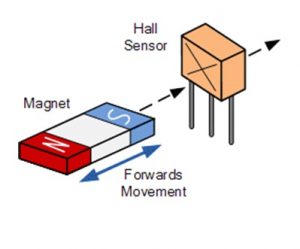

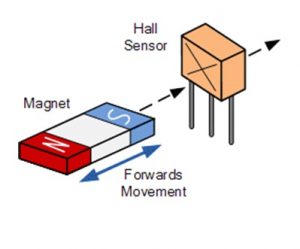

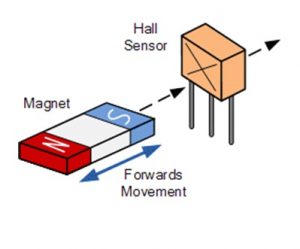

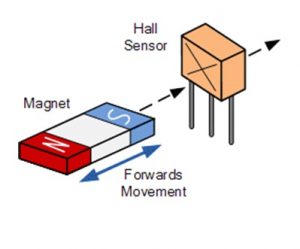

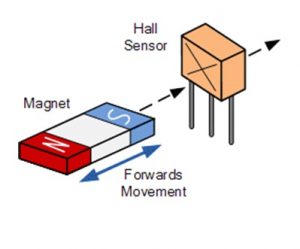

3.-Hall effect :

Hall effect sensor is a device that uses to measure the magnitude of a magnetic field. Its output voltage is directly proportional to the magnetic field strength through it.

Hall effect sensors used for proximity sensing, positioning, speed detection, and current sensing applications. Frequently, a Hall sensor combines with threshold detection so that it acts as a switch.

5.Ultrasonic Proximity Switch:

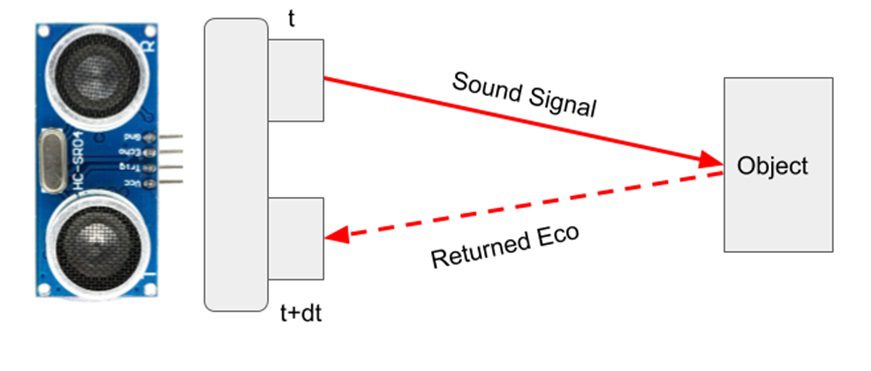

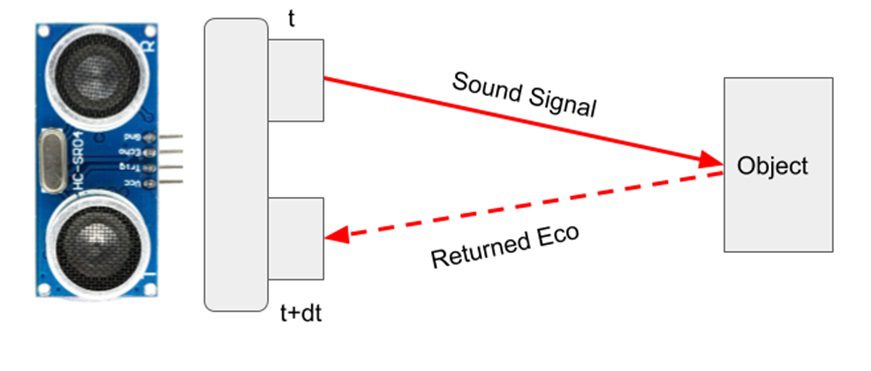

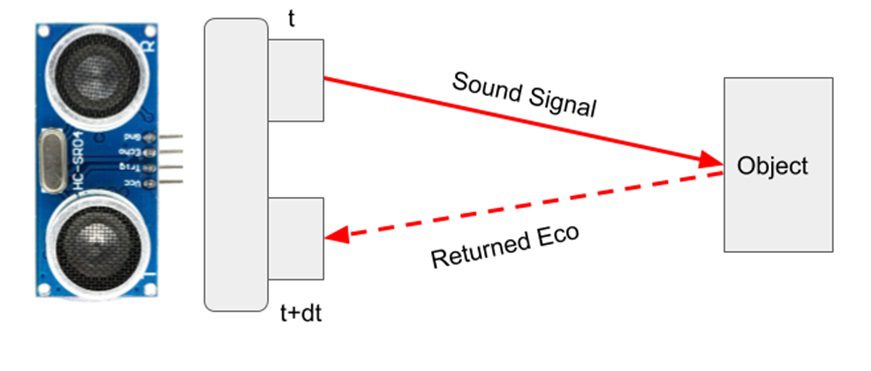

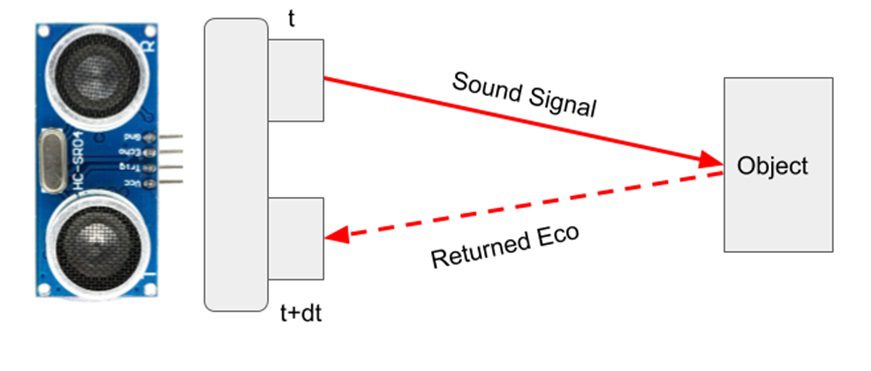

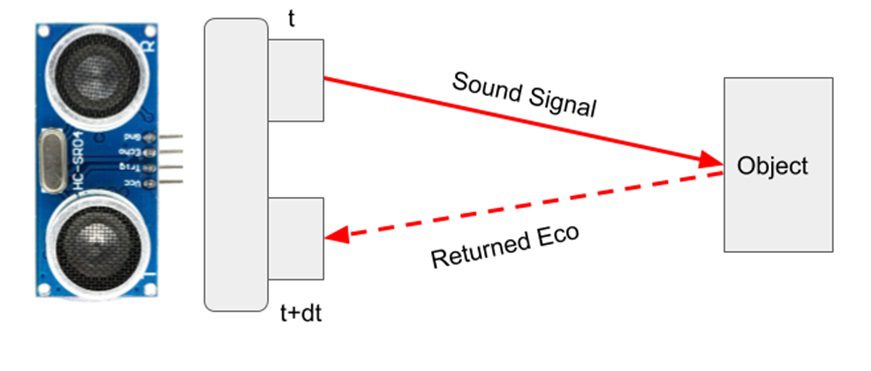

Ultrasonic Proximity switch consist a ultrasonic sensor which works at a frequency of 40 kHz. It uses two specially made ultrasonic transducers: One transducer emits 40kHz sound, while the other receives 40kHz sound and converts it into electrical variation of the same frequency. Ultrasonic proximity sensors operate by emitting and receiving high-frequency sound waves.

Working Principle: Ultrasonic proximity sensors emit and receive sound waves. The carrier signal is a high frequency, inaudible sound wave. They detect the presence of the target object in one of two configurations.

Diffuse or Reflective sensors have the transmitter and receiver packaged in the same housing. When a target enters the sensing range of the device, the ultrasonic waves are reflected back to the sensor.

Opposed or Thru-Beam sensors have the transmitter and receiver packaged separately. The receiver is mounted facing the transmitter and when an object enters the sensing range of an opposed sensor, it blocks the transmitted signal. Rather than activating the trigger when the frequency is received, the trigger is activated when the signal is broken.

Read Also:-

Remote seal DP transmitter Calibration