A level transmitter is a device used to measure the level of a liquid or solid material in a tank or vessel. It is an essential component of many industrial processes, such as chemical manufacturing, oil and gas production, and water treatment.

The principle of operation of a level transmitter is based on the measurement of the pressure exerted by the material in the tank. The transmitter consists of a sensor that is mounted on the tank and connected to a processing unit. The sensor measures the pressure exerted by the material on its surface and converts it into an electrical signal.

The electrical signal is then processed by the transmitter’s electronics to provide a reading of the material level in the tank. This reading can be displayed on a local indicator or transmitted to a remote control system for further processing.

Level transmitter types

There are several types of level transmitters available, each with its own advantages and limitations. The most common types are:

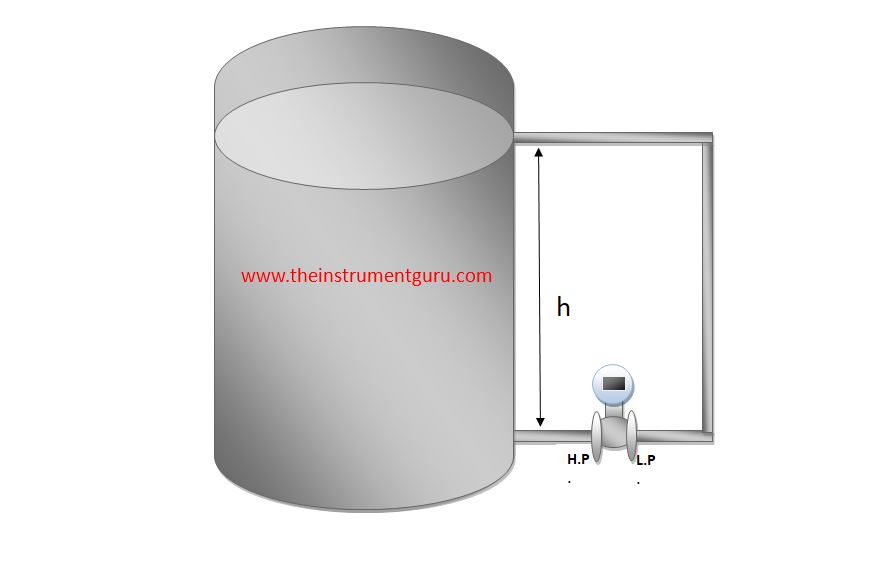

- Differential Pressure (DP) Level Transmitter: DP level transmitters work by measuring the difference in pressure between the top and bottom of the tank. This difference is proportional to the level of the material in the tank. DP level transmitters are simple and reliable, but they require periodic calibration and are sensitive to changes in temperature and pressure.

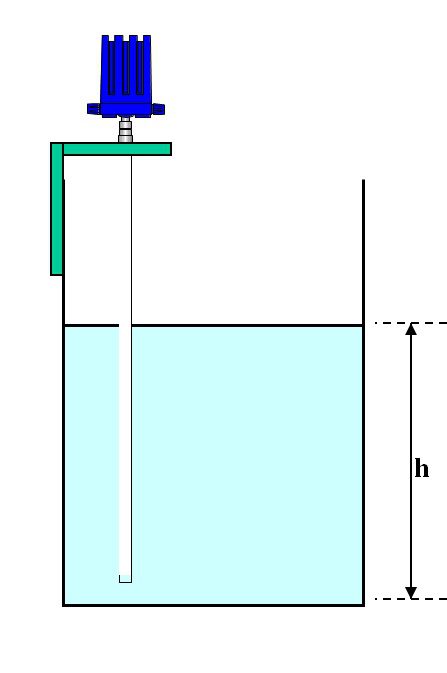

- Guided Wave Radar (GWR) Level Transmitter: GWR level transmitters use microwave signals that travel along a probe inserted into the tank. The signal is reflected back when it encounters the material in the tank, and the time taken for the signal to return is used to calculate the level. GWR level transmitters are very accurate and can work in high-temperature and high-pressure environments.

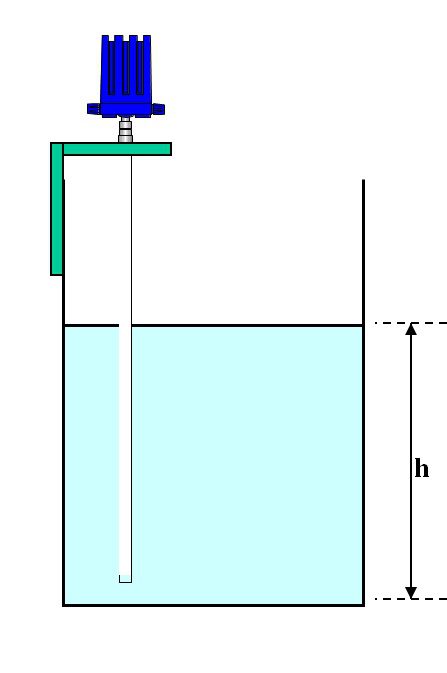

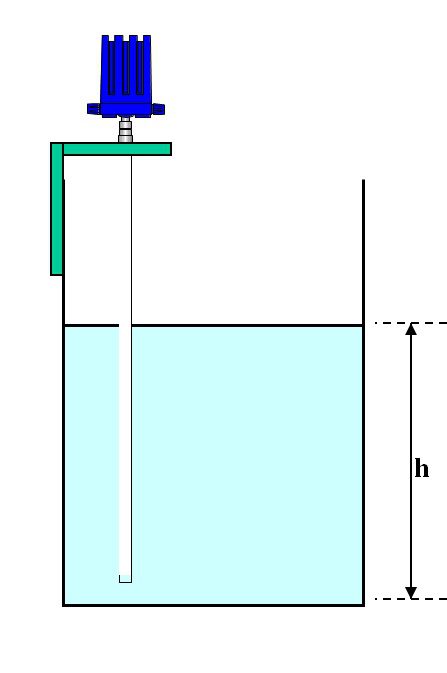

- Ultrasonic Level Transmitter: Ultrasonic level transmitters use high-frequency sound waves to measure the distance between the sensor and the material in the tank. The time taken for the sound wave to bounce back is used to calculate the level of the material. Ultrasonic level transmitters are easy to install and maintain, but they are sensitive to changes in temperature, pressure, and material density.

ULTRASONIC L TX - Capacitance Level Transmitter: Capacitance level transmitters use the principle of capacitance to measure the level of material in the tank. The sensor is a capacitor with two electrodes, one of which is mounted on the tank wall and the other on a probe that extends into the tank. The capacitance between the electrodes is proportional to the level of the material in the tank. Capacitance level transmitters are reliable and accurate, but they can be affected by changes in material composition and temperature.

Conclusion

In conclusion, level transmitters are critical components of industrial processes that require accurate measurement and control of material levels. The choice of level transmitter depends on the application requirements, such as accuracy, reliability, and environmental conditions. By choosing the right level transmitter, industries can improve their operational efficiency, reduce waste, and ensure product quality and safety.

Read Also